Roller Coating Production Line: The Application of High-Efficiency Coating Technology

October 21, 2024

October 21, 2024 Hits:228second

Hits:228secondIn the modern manufacturing industry, the application of coating technology is becoming increasingly widespread, especially in fields such as automotive, construction, and aerospace. The roller coating production line, also known as the roll coating production line, is a highly efficient and automated coating equipment capable of uniformly coating substrates.

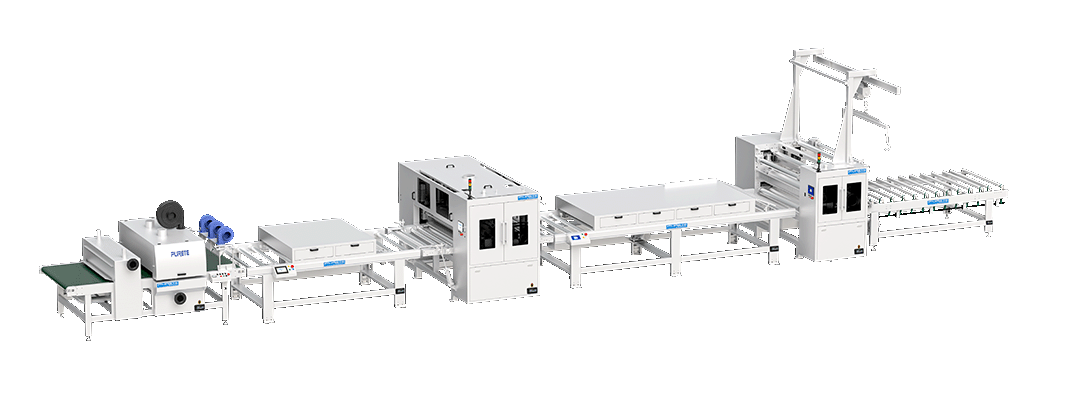

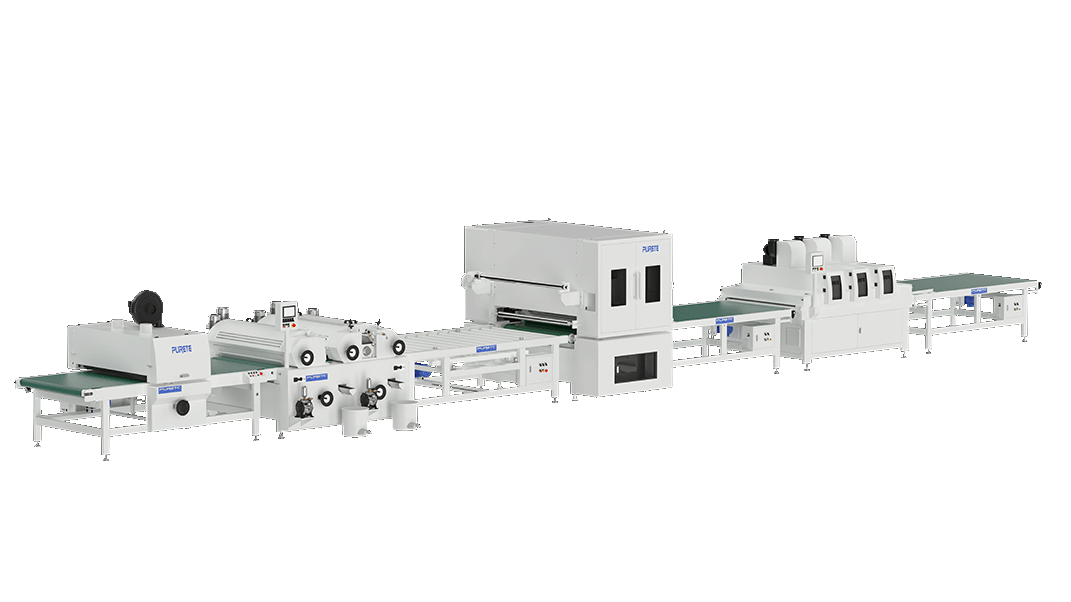

Equipment Composition

The roller coating production line mainly consists of coating machines, curing chambers, cooling rooms, and packaging equipment. The coating machine is the core of the entire production line, responsible for uniformly coating the paint on the substrate. The curing chamber is used for the drying and curing of the paint, while the cooling room ensures the stability of the coating, and the packaging equipment is responsible for the final packaging of the products.

Working Principle

The working principle of the roller coating production line mainly relies on the combination of multiple rollers. These rollers, through different arrangements and combinations, can handle various viscosities of coating liquids and are suitable for different coating film thicknesses. The working method of the coating machine can be classified according to the state of the coating liquid before coating, and the measurement and determination of the coating amount before or after coating.

Gravure Coating: The engraving roller is processed to form a concave-convex shape on the surface, and the coating liquid attached to the engraving roller is scraped off with a scraper, and the liquid accumulated in the concave part is used to coat the web roll of the coated material. This method is suitable for coatings that require specific patterns or textures.

Reverse Coating: Composed of a coating roller, a support roller, and a metering roller, the coating liquid is transferred to the web roll of the base material by rotating the support roller and the coating roller in the same direction. The film thickness depends on the gap between the coating roller and the metering roller, as well as the speed of the rollers.

Slot Die Coating: Utilizing the technology of plastic film extrusion molding, the coating liquid passes through the "die" to produce a uniform liquid film, which then contacts the base material for coating. This method can achieve stable coating and is suitable for high-viscosity coating liquids and the formation of thick films.

Lip Coating: The coating liquid is supplied to the lip-type nozzle, and the coating is carried out by contacting the moving base material. This method can achieve precise control of the coating amount.

Operational Process

Preparation Work: Before use, it is necessary to check whether the equipment is working normally, such as whether the electrical system is powered, whether the transmission system is flexible, and whether the conveyor belt is tightened. At the same time, select the appropriate raw materials according to the product requirements and ensure that their quality meets the standards.

Parameter Setting: Set parameters according to product requirements, such as speed, temperature, and pressure. These parameters directly affect the uniformity of the coating and the quality of the coating.

Adjusting the Coating Head: Adjust the position and angle of the coating head according to the product requirements and ensure that it maintains an appropriate distance from the conveyor belt. This step is crucial as it determines the uniformity and film thickness of the coating.

Coating: The coating machine uniformly coats the paint on the substrate through the rollers, forming the required coating film thickness. The uniformity and quality of the coating must be closely monitored during the coating process.

Curing: After coating, the substrate enters the curing chamber and is cured through hot air circulation or other heating methods to ensure the drying and curing of the coating. The curing process requires strict control of temperature and time to prevent excessive drying or incomplete curing of the coating.

Cooling: The cured substrate enters the cooling room for cooling treatment to ensure the stability and hardness of the coating.

Packaging: The cooled finished products are packaged and prepared for shipment. The packaging process needs to ensure the integrity of the product and protect the coating from damage.

Application Fields

The roller coating production line is not only suitable for the coating of thin flat materials such as films and sheets but can also perform continuous high-speed coating on wider and longer substrates. This production line is widely used in various industrial fields such as electronic components, optical/LCD products, food, and pharmaceuticals. Its efficient and uniform coating capability has made it an important position in the manufacturing industry.

The roller coating production line, with its efficient coating technology and automated operational process, greatly improves production efficiency and product quality. With the continuous advancement of technology, the application of the roller coating production line in the manufacturing industry will become more and more extensive, providing a reliable production guarantee for various coated products.