Short-Cycle Press Production Line: The Secret to Fast and Efficient Production

December 19, 2024

December 19, 2024 Hits:197second

Hits:197secondIn today’s competitive manufacturing landscape, the demand for speed, efficiency, and high-quality products has never been higher. The short-cycle press production line has emerged as a game-changer, offering unparalleled benefits for industries like furniture, construction, and automotive. Here’s a deep dive into why this technology is revolutionizing production processes.

What is a Short-Cycle Press Production Line?

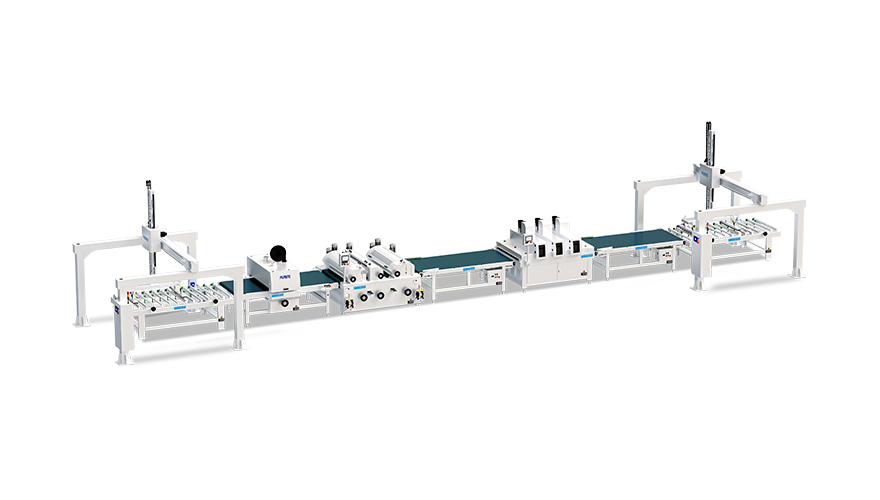

A short-cycle press production line is a highly automated system designed for rapid lamination or pressing processes. It applies pressure, heat, and sometimes adhesives to bind materials like wood, veneers, laminates, or composites into finished panels or components. These machines are engineered for fast cycle times, often completing a production cycle in less than a minute.

Key Features of a Short-Cycle Press Production Line

1. High-Speed Operation: Optimized for short cycle times, significantly boosting productivity.

2. Precision Engineering: Ensures consistent pressure and temperature distribution for uniform results.

3. Automation: Integrated systems for loading, pressing, and unloading minimize manual intervention.

4. Versatility: Supports a variety of materials and finishes, including decorative laminates and veneers.

Benefits of a Short-Cycle Press Production Line

1. Increased Productivity

· Rapid Cycle Times: Short pressing cycles mean more products can be manufactured in less time.

· Continuous Operation: Advanced lines can run 24/7, maximizing output.

2. Superior Quality

· Uniform Pressure and Temperature: Guarantees a flawless surface finish and strong bonding.

· Reduced Defects: Automation minimizes errors, ensuring consistent quality across batches.

3. Cost Efficiency

· Lower Labor Costs: Automation reduces the need for manual handling.

· Energy Efficiency: Optimized systems consume less energy per cycle compared to traditional methods.

· Minimal Waste: Precise operation reduces material waste.

4. Versatility

· Wide Application Range: Can be used for laminating furniture panels, flooring, and automotive interior components.

· Customizable Finishes: Handles a variety of surface finishes, from high-gloss to textured designs.

5. Easy Integration

· Scalability: Can be seamlessly integrated into existing manufacturing lines.

· Compatibility: Works with a variety of adhesives and surface materials.

6. Environmental Benefits

· Reduced Waste: Optimized processes ensure efficient use of materials.

· Energy Optimization: Advanced technologies minimize energy consumption and emissions.

Applications of Short-Cycle Press Production Lines

· Furniture Manufacturing: Laminating particle boards and MDF for cabinets, tables, and more.

· Flooring Production: Creating durable and decorative laminate flooring.

· Automotive Industry: Producing interior panels and components.

· Construction Materials: Fabricating high-strength, aesthetically appealing wall panels and doors.

Why Invest in a Short-Cycle Press Production Line?

For manufacturers aiming to stay competitive, investing in a short-cycle press production line is a strategic move. It combines speed, quality, and cost-efficiency, enabling businesses to meet high demand without compromising on quality.

By leveraging this advanced technology, manufacturers can not only streamline their operations but also enhance their market positioning with reliable, high-quality products.