Applications of Intelligent Coating Machine Systems Across Industries

January 06, 2025

January 06, 2025 Hits:144second

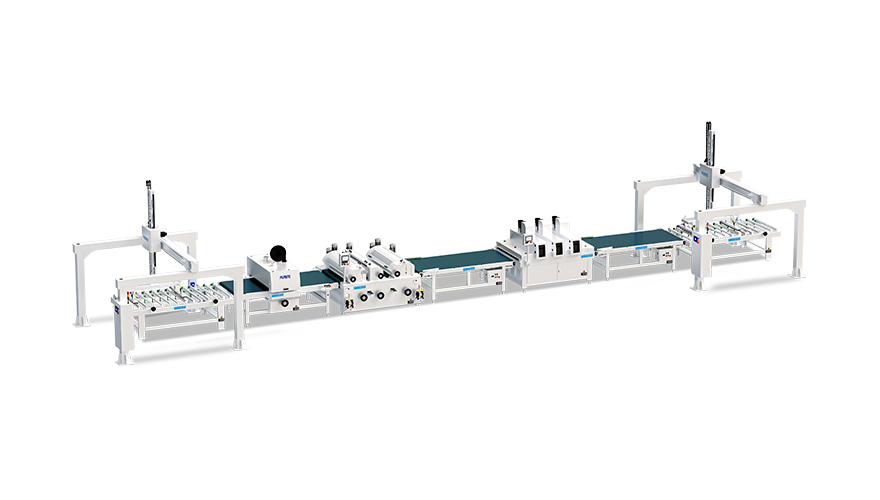

Hits:144secondIntelligent coating machine systems have revolutionized the way materials are coated in modern manufacturing. By integrating cutting-edge technologies like artificial intelligence (AI), real-time monitoring, and automated controls, these systems deliver exceptional precision, efficiency, and adaptability. Their applications span a wide range of industries, meeting diverse requirements from protective coatings to aesthetic finishes. This article explores how intelligent coating systems are utilized across various industrial sectors.

1. Electronics Industry

In the electronics industry, precision is paramount, and intelligent coating systems are indispensable for ensuring the reliability and durability of products. Key applications include:

Printed Circuit Boards (PCBs): Protective coatings are applied to safeguard circuits from moisture, dust, and chemical exposure.

Sensors and Components: Thin and uniform coatings enhance performance and provide resistance against environmental factors.

Flexible Electronics: The adaptability of intelligent systems enables effective coating of flexible and irregular surfaces, crucial in modern electronics.

The integration of real-time feedback ensures consistency in coating thickness and minimizes defects, critical for maintaining quality standards in sensitive electronics.

2. Medical Devices

The medical field demands high levels of precision and biocompatibility, making intelligent coating systems vital. Applications include:

Drug Delivery Systems: Coatings regulate drug release rates, improving treatment efficacy.

Diagnostic Tools: Protective layers enhance the durability and accuracy of devices like test strips and sensors.

Implants and Prosthetics: Advanced coatings ensure biocompatibility and long-term functionality in medical implants.

The ability to monitor and adjust parameters in real time ensures compliance with stringent medical standards and optimizes product performance.

3. Automotive Industry

In the automotive sector, intelligent coating systems are used to enhance both the functionality and aesthetics of vehicles. Applications include:

Anti-Corrosion Coatings: Protecting metal components like chassis and engine parts from rust and wear.

Aesthetic Finishes: Applying smooth, even layers of paint or decorative finishes to achieve high-quality visual appeal.

Specialty Coatings: Heat-resistant or UV-protective layers for specific vehicle components.

Automated controls and adaptive technologies ensure uniform application, reducing waste and improving production efficiency.

4. Packaging Industry

Packaging materials often require protective or decorative coatings to enhance functionality and appeal. Intelligent systems are used for:

Food Packaging: Coatings provide moisture and oxygen barriers, extending shelf life.

Decorative Layers: High-quality finishes for branding and visual appeal.

Recyclable Materials: Ensuring eco-friendly coatings compatible with sustainable practices.

Real-time monitoring and precise control help achieve consistent results, ensuring high throughput in packaging production lines.

5. Renewable Energy Sector

The renewable energy industry relies on intelligent coating systems to enhance the efficiency and durability of equipment. Applications include:

Solar Panels: Anti-reflective and protective coatings improve energy absorption and longevity.

Wind Turbines: Protective layers shield components from harsh environmental conditions.

Energy Storage Systems: Advanced coatings ensure the safety and performance of batteries and other storage devices.

The adaptability of intelligent systems makes them ideal for handling the unique requirements of renewable energy components.

6. Textile Industry

In textiles, intelligent coating systems enhance functionality and aesthetics. Key uses include:

Waterproofing: Applying water-repellent layers to outdoor and sportswear.

Flame Resistance: Coatings that add fire-retardant properties to fabrics for industrial or home use.

Aesthetic Finishes: Decorative coatings that add textures or colors to enhance fabric appearance.

The precision of intelligent systems ensures uniform application, even on large or complex surfaces, maintaining quality while minimizing material waste.

7. Construction Materials

Construction materials benefit from intelligent coatings to improve durability, functionality, and appearance. Applications include:

Glass Coatings: Anti-glare and self-cleaning layers for windows and facades.

Steel and Wood: Protective coatings enhance resistance to corrosion, moisture, and UV damage.

Insulating Layers: Thermal or acoustic coatings improve energy efficiency and comfort in buildings.

Advanced monitoring ensures consistent performance, even in high-volume production settings, supporting large-scale construction projects.

Intelligent coating machine systems have become essential in modern manufacturing, offering unparalleled precision, efficiency, and adaptability. From electronics and medical devices to automotive and renewable energy applications, these systems address the unique needs of each industry. By leveraging advanced technologies such as AI, real-time monitoring, and adaptive controls, they deliver superior results while reducing waste and optimizing energy usage. As industries continue to evolve, the role of intelligent coating systems will only grow, driving innovation and sustainability across diverse sectors.