The Application of Spray Painting Machines in Wooden Door and Cabinet Coating

February 05, 2025

February 05, 2025 Hits:7second

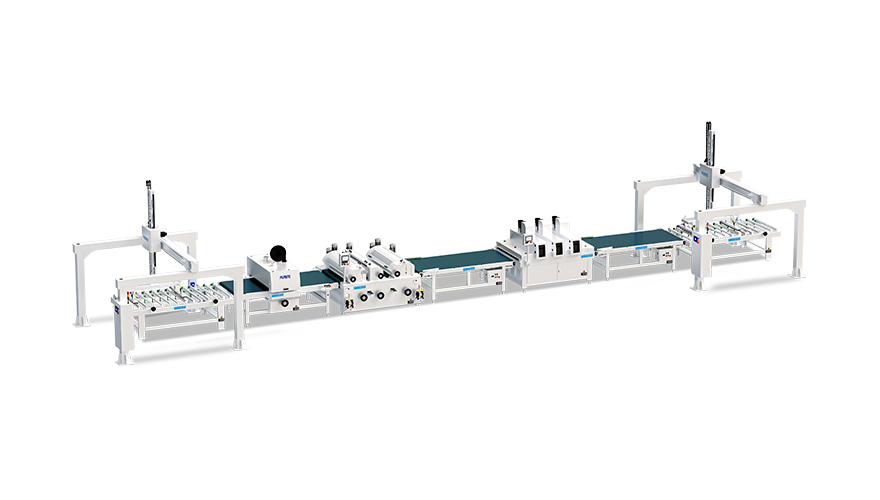

Hits:7secondSpray painting machines have revolutionized the coating industry, particularly in the realm of wooden doors and cabinets. These machines offer unparalleled precision, efficiency, and versatility, making them indispensable in modern manufacturing processes.

Wooden Door Coating

Wooden doors are a staple in both residential and commercial settings, and their aesthetic appeal is largely determined by the quality of their coating. Spray painting machines have become the go-to solution for achieving a variety of finishes on wooden doors, including high-gloss, matte, and wood-grain effects.

High-Gloss and Matte Finishes:

High-gloss finishes are popular for their sleek, reflective surfaces that add a touch of elegance to any space. Spray painting machines can evenly distribute high-gloss coatings, ensuring a smooth, mirror-like finish. On the other hand, matte finishes are favored for their understated, non-reflective appearance, which can be equally striking. The precision of spray painting machines ensures that these finishes are applied uniformly, without streaks or bubbles.

Wood-Grain Effects:

For those seeking a more natural look, spray painting machines can replicate the intricate patterns of wood grain. This is particularly useful for composite wood doors, which may not have the natural grain of solid wood. By using specialized nozzles and techniques, these machines can create realistic wood-grain effects that are virtually indistinguishable from the real thing.

Versatility Across Materials:

Spray painting machines are not limited to a specific type of wooden door. They can be used on a variety of materials, including flat-panel doors, composite wood doors, and solid wood doors. This versatility makes them a valuable asset in any door manufacturing facility.

Cabinet Coating

Cabinets are another area where spray painting machines excel. The coating process for cabinets often involves multiple layers, including UV coatings, colored paints, and transparent varnishes. Spray painting machines can handle these complex processes with ease, ensuring a high-quality finish every time.

UV Coatings:

UV coatings are widely used in cabinet manufacturing due to their durability and quick curing times. Spray painting machines can apply UV coatings evenly, ensuring that the entire surface is protected. This is particularly important for cabinets, which are subject to frequent use and need to withstand wear and tear.

Colored Paints and Transparent Varnishes:

Spray painting machines are also adept at applying colored paints and transparent varnishes. Whether you're looking for a bold, modern look or a more traditional, natural finish, these machines can deliver. The ability to switch between different colors and finishes quickly makes them ideal for custom cabinet designs.

Smooth Surfaces and High-Gloss Effects:

Modern home designs often feature cabinets with smooth, high-gloss surfaces. Achieving this look requires a high level of precision, which spray painting machines can provide. The machines can apply multiple thin layers of paint, resulting in a flawless, reflective surface that enhances the overall aesthetic of the kitchen or bathroom.

Edge and Detail Processing

One of the standout features of spray painting machines is their ability to handle intricate edges and details. This is particularly important for cabinets and doors with complex designs.

High-Precision Nozzles:

Spray painting machines are equipped with high-precision nozzles that can evenly coat even the most intricate edges. This ensures that every part of the door or cabinet is covered, leaving no room for imperfections. This level of precision is especially valuable for custom furniture designs, where attention to detail is paramount.

Uniform Coating on Complex Shapes:

Whether it's a curved cabinet door or a door with intricate carvings, spray painting machines can achieve a uniform coating. This is crucial for maintaining the aesthetic integrity of the design and ensuring that the final product meets the highest standards of quality.

Mass Customization

In today's market, customization is key. Consumers are increasingly seeking unique, personalized designs, and spray painting machines are well-equipped to meet this demand.

Rapid Color and Texture Changes:

One of the most significant advantages of spray painting machines is their ability to quickly switch between different colors and textures. This is particularly useful for manufacturers who offer a wide range of customization options. Whether it's a specific color match or a unique texture, spray painting machines can deliver without the need for extensive downtime.

Meeting Diverse Customization Needs:

The ability to rapidly change colors and textures allows manufacturers to cater to a diverse range of customer preferences. This flexibility is essential in a competitive market, where the ability to offer unique, customized products can set a brand apart.

Spray painting machines have transformed the coating process for wooden doors and cabinets, offering a level of precision, efficiency, and versatility that was previously unattainable. From high-gloss finishes to intricate wood-grain effects, these machines can achieve a wide range of aesthetic outcomes. Their ability to handle complex edges and details, coupled with their capacity for rapid color and texture changes, makes them an invaluable asset in modern manufacturing. As the demand for customized, high-quality finishes continues to grow, spray painting machines will undoubtedly play a central role in meeting these needs.