Key Technologies and Application Scenarios of Spray Painting Machines in Wood Door Coating

January 13, 2025

January 13, 2025 Hits:116second

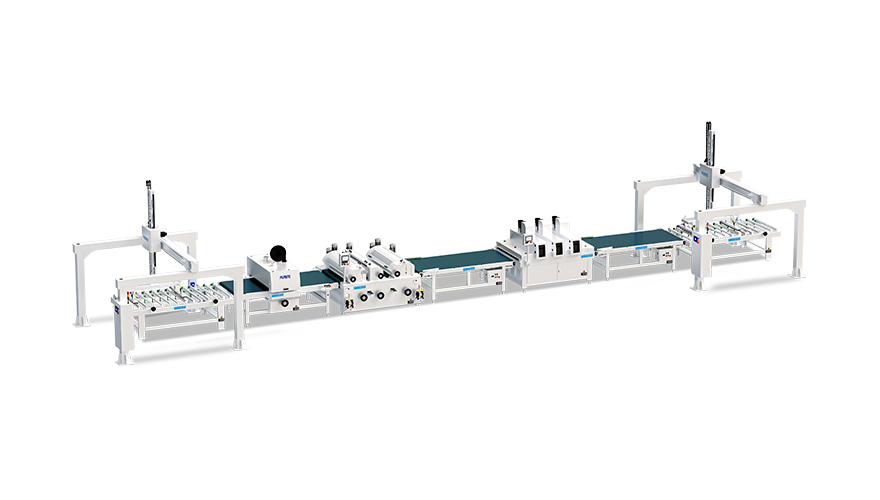

Hits:116secondAs the demand for surface coating quality, production efficiency, and environmental protection continues to rise in the wood door industry, spray painting machines have become an essential part of modern wood door coating processes. With their high efficiency, precision, and eco-friendly features, spray painting machines are transforming the wood door manufacturing industry.

Key Technologies of Spray Painting Machines in Wood Door Coating

1. Automated Coating Technology

The core advantage of spray painting machines lies in automation. Using robotic sprayers or CNC-controlled arms, spray painting machines precisely coat every part of a wood door, including complex edges and grooves. This automation reduces manual intervention and significantly improves coating efficiency.

2. Electrostatic Spraying Technology

Electrostatic spraying uses static electricity to evenly attract paint particles onto the wood door surface, minimizing paint waste and achieving uniform coatings. This technology is particularly suitable for large-scale production requiring high-quality surface finishes.

3. High-Speed Rotational Spraying

High-speed rotary atomizers break paint into fine particles for an even spray, ensuring smooth and glossy coatings on wood doors. This is especially beneficial for high-gloss or matte finishes.

4. Precision Control Systems

Modern spray painting machines are equipped with advanced control systems that adjust spray paths, speeds, and paint volumes based on the dimensions, shapes, and coating requirements of wood doors. Such precise control reduces paint waste and enhances coating consistency.

5. Eco-Friendly Coating Technology

Many spray painting machines are compatible with water-based paints and low-VOC (volatile organic compound) coatings, reducing environmental pollution during the painting process and meeting the demands for green manufacturing.

Application Scenarios of Spray Painting Machines in Wood Door Coating

1. High-End Wood Door Surface Coating

High-end wood doors often require complex multi-layer coating processes, such as primer, base coat, and topcoat. Spray painting machines seamlessly handle these layers with precise settings, ensuring uniform and high-quality finishes.

2. Customized Wood Door Coating

With the rise of customized furniture, wood door designs have become increasingly diverse in shape and size. Spray painting machines’ flexibility allows them to meet the coating needs of various complex shapes, ensuring every door aligns with customer specifications.

3. Mass Production of Wood Doors

In mass production, spray painting machines excel with their high efficiency and consistency. By operating in assembly-line setups, these machines continuously coat multiple doors, reducing production cycles and boosting efficiency.

4. Coating of Irregular-Shaped Wood Doors

The edges and intricate textures of irregular-shaped wood doors pose challenges for traditional coating methods. Spray painting machines, with their multi-axis robotic arms and flexible spray nozzles, easily cover hard-to-reach areas, ensuring complete and uniform coatings.

5. Eco-Friendly Wood Door Manufacturing

For manufacturers prioritizing eco-friendly practices, spray painting machines support the use of low-VOC and water-based paints, reducing environmental impact. Additionally, automated spraying minimizes overspray and waste, further reducing production costs.

Advantages of Spray Painting Machines in Wood Door Coating

1. Increased Production Efficiency

Automated operations in spray painting machines significantly reduce coating time while ensuring consistency and high efficiency in production.

2. Improved Coating Quality

Modern spray painting machines achieve uniform paint distribution, resulting in smoother, flawless surfaces, enhancing the aesthetic and commercial value of wood doors.

3. Reduced Labor Costs

Compared to manual painting, spray painting machines drastically cut labor requirements, reducing operational costs and minimizing errors caused by human intervention.

4. Support for Eco-Friendly Production

Spray painting machines’ compatibility with eco-friendly coatings and precision control systems minimizes VOC emissions and paint waste, aligning with green manufacturing goals.

5. Adaptability to Diverse Needs

Whether for standardized mass production or personalized custom designs, spray painting machines deliver efficient and precise coating solutions.

Future Development Trends

1. Intelligence and Digitization

With the advancement of smart manufacturing, spray painting machines will increasingly integrate AI and IoT technologies, enabling remote monitoring, parameter optimization, and intelligent maintenance.

2. Enhanced Eco-Friendly Features

Future spray painting machines will further improve their environmental performance by supporting a broader range of low-VOC paints and developing more efficient exhaust treatment systems.

3. Multi-Functional Equipment Development

Spray painting machines are expected to evolve into multi-functional devices that combine coating, drying, and quality inspection, further boosting production efficiency.

Spray painting machines play a vital role in wood door coating by leveraging automated, precise, and eco-friendly technologies to provide high-efficiency and high-quality coating solutions. Whether addressing mass production or meeting individual customization needs, spray painting machines demonstrate unparalleled advantages. As technology continues to advance and environmental regulations tighten, the application prospects of spray painting machines in wood door coating will become even broader, providing robust support for the high-quality development of the furniture industry.