The Working Principle of the Short-Cycle Press

January 22, 2025

January 22, 2025 Hits:94second

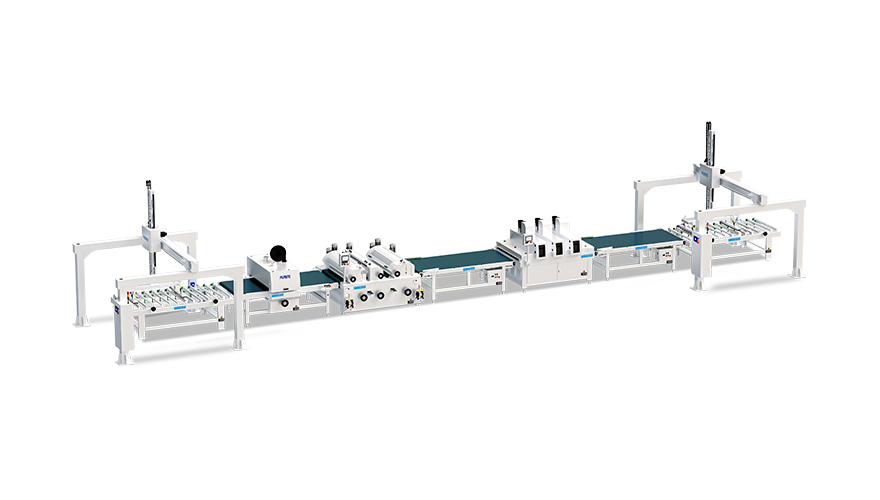

Hits:94secondThe short-cycle press is a highly efficient machine designed for the production of laminated wood-based panels, widely used in decorative panels, furniture components, and flooring. Its core principle involves utilizing high temperature, high pressure, and precise cycle control to bond decorative materials (such as melamine-impregnated paper) firmly to the surface of a substrate. Below is a breakdown of the working principle of the short-cycle press:

1. Preheating Stage: Ensuring Compatibility Between Substrate and Decorative Paper

Before the pressing process begins, the short-cycle press preheats the equipment and materials using an integrated heating system.

· Heating of Substrate and Decorative Paper: The heating system (typically electric or thermal oil circulation) raises the temperature to a specified range, ensuring that the adhesive layer cures effectively during the pressing process.

· Uniform Temperature Distribution: The high thermal conductivity of the hot pressing plates ensures even heat distribution across the substrate and decorative paper, avoiding localized overheating or cooling.

The goal of this stage is to activate the resin in the decorative paper and the adhesive on the substrate’s surface to enhance bonding performance.

2. Pressing Stage: High Temperature and Pressure from the Hot Press Plates

During the pressing stage, the short-cycle press applies high temperature and high pressure to the substrate and decorative paper via a hydraulic system.

2.1 Role of Pressure

· The hydraulic system generates high pressure to bond the decorative paper tightly to the substrate, eliminating air bubbles and gaps between them.

· Different materials require different pressing pressures. For instance, MDF may need higher pressure to ensure bonding strength, while particleboard might require slightly lower pressure.

2.2 Role of Temperature

· The hot press plates maintain a high temperature (typically between 150°C and 200°C), ensuring the melamine resin in the decorative paper cures fully and forms a strong chemical bond with the substrate.

· High temperatures also ensure even coloration of the decorative paper while preventing wrinkles or detachment.

2.3 Time Control

· The pressing time usually ranges from 10 to 30 seconds, depending on the material type, thickness, and adhesive characteristics.

· The short-cycle press achieves rapid pressing with precise time control, ensuring consistent product quality.

3. Cooling Stage: Stabilizing Surface Performance

After pressing, the short-cycle press initiates a cooling process.

· Cooling System: Cooling is achieved through water circulation or air-cooling systems to rapidly lower the temperature of the hot press plates and materials.

· Function: Cooling helps solidify the resin structure, stabilize panel dimensions, and prevent warping or deformation.

Once the cooling stage is complete, the press automatically separates the hot plates from the finished product, which is then transferred to the next processing step.

4. Automation and Intelligent Control

Modern short-cycle presses leverage advanced automation and intelligent control systems to optimize the entire operation:

· Automatic Loading and Unloading: Fully automated loading and unloading systems reduce manual labor, boosting production efficiency.

· Real-Time Parameter Monitoring: Sensors monitor key parameters such as temperature, pressure, and time in real-time, ensuring each panel meets the set standards.

· Smart Adjustments: The system can automatically adjust pressing parameters based on the type of substrate and decorative paper, accommodating diverse production requirements.

5. Workflow Summary

The core workflow of a short-cycle press can be summarized as follows:

1. Preheating Stage: Heating the press plates, substrate, and decorative paper to prepare materials for optimal bonding.

2. Pressing Stage: Applying high temperature and pressure to bond the decorative paper and substrate tightly.

3. Cooling Stage: Reducing the temperature to solidify materials and stabilize the panel’s dimensions and performance.

4. Unloading and Inspection: Automatically unloading the finished product for quality inspection and subsequent processing.

Key Features of the Short-Cycle Press

1. Rapid Cycles: Short pressing times enable high production efficiency, making it ideal for mass production.

2. High-Precision Control: Accurate regulation of temperature, pressure, and time ensures consistent product quality.

3. Energy Efficiency: The use of energy recovery and optimized designs reduces energy consumption while supporting environmentally friendly adhesives.

4. Versatility: Capable of handling various substrates (such as MDF and particleboard) and decorative materials, meeting diverse market demands.

Applications

Short-cycle presses are widely used in:

· Furniture Manufacturing: Producing durable and aesthetically pleasing surfaces for tabletops, cabinet doors, and wardrobes.

· Flooring Production: Laminating high-strength decorative layers to meet wear resistance and moisture-proof requirements.

· Decorative Panels: Creating wall panels, partitions, and other decorative materials with diverse surface textures and effects.

The short-cycle press plays a crucial role in wood-based product manufacturing with its efficient and precise laminating capabilities. By leveraging advanced temperature, pressure, and time control, along with the integration of automation and intelligent technologies, the short-cycle press meets modern production demands for efficiency and quality. It provides robust technical support for the decorative panel industry’s growth, ensuring high-quality outputs for various applications.