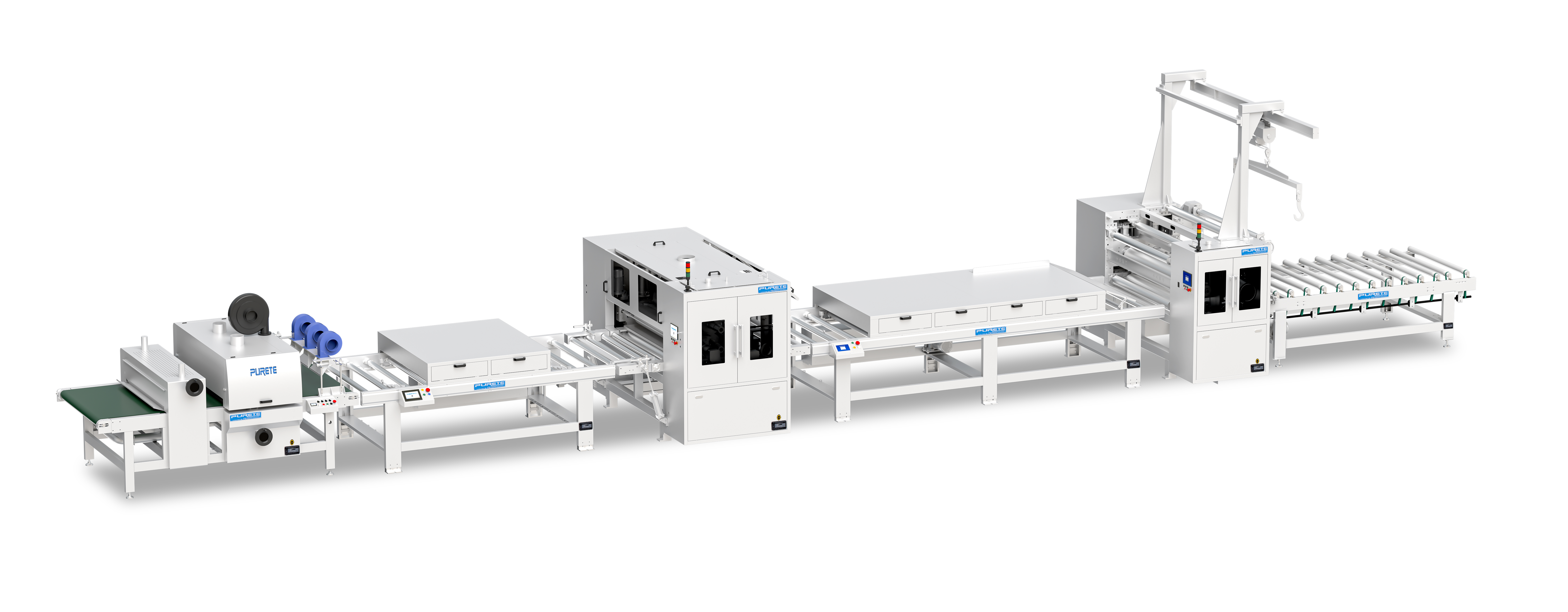

T1 Automatic Laminating Production Line

The T1 Automatic Laminating Production Line is designed for high-efficiency lamination of both sheet and coil materials, such as PET, PETG, PP, PVC, CPL, HPL, acrylic, aluminum foil, and SPC panels. It provides precise temperature and pressure control to ensure strong adhesion, bubble-free surfaces, and durable decorative finishes.

This automatic PUR laminating line supports large-scale continuous production, offering superior flexibility for different substrate types and coating materials. It is widely used in furniture manufacturing, interior wall panels, cabinets, and decorative board production.

Composed of: Double-surface dust cleaner, infrared preheating machine, gluing machine, sheet feeding station, and laminating machine.

Read more

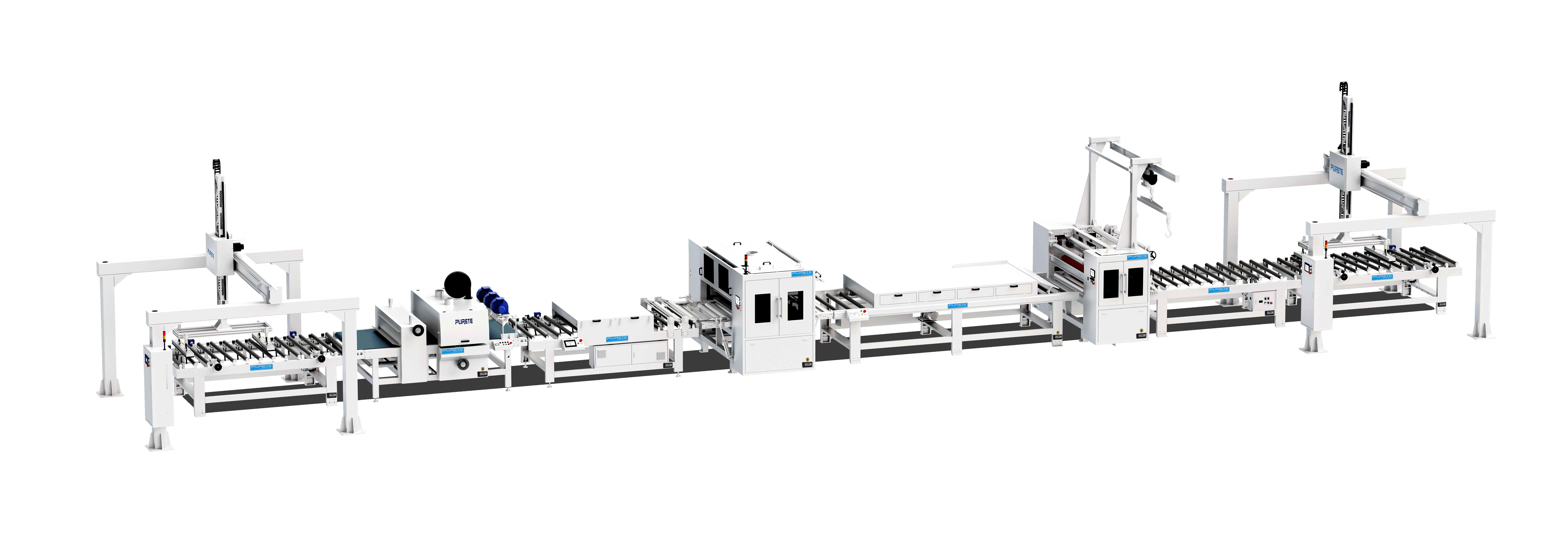

T2 Automatic Laminating Production Line

The T2 Automatic Laminating Production Line is designed for high-efficiency, automated panel lamination, integrating a gantry loading and unloading system to significantly reduce manual handling and labor intensity. This intelligent setup improves production efficiency, safety, and operational precision, making it ideal for continuous large-scale manufacturing.

The line supports PUR and hot-melt adhesive lamination for various substrates such as MDF, plywood, PET, PVC, and decorative sheets. It ensures smooth surface finishes, strong bonding, and uniform coating quality—perfect for furniture, doors, and interior wall panels.

Composed of: Gantry loading, polishing and dust removal system, gluing machine, laminating machine, and unloading system.

Read more

T3 Automatic Laminating Production Line

The T3 Automatic Laminating Production Line is a fully automated, high-capacity lamination system designed for continuous production without human intervention. It integrates advanced material handling, precise trimming, and high-efficiency lamination technology to ensure stable performance, consistent adhesion, and superior surface quality across large production volumes.

This line is ideal for manufacturers requiring high-speed PUR lamination, decorative panel production, and mass customization for furniture, cabinets, doors, and wall panels. Its automated workflow reduces labor costs, enhances accuracy, and maintains reliable quality across every board.

Composed of: Gantry loading, 8-edge trimming unit, sanding machine, gluing machine, laminating machine, short-edge film cutting system, board flipping machine, and unloading unit.

Read more