What are the common applications of PUR laminating machines in the printing industry?

December 13, 2024

December 13, 2024 Hits:42second

Hits:42secondPUR laminating machines (Polyurethane Reactive laminating machines) are widely used in the printing industry for their ability to create high-quality, durable, and flexible laminated products. Here are the common applications of these machines in the printing industry:

1. Bookbinding

· Hardcover Books: PUR laminating machines provide a robust adhesive layer that enhances the durability and longevity of hardcover books.

· Softcover Books: The flexible bond created by PUR is ideal for softcover books, preventing cracking at the spine and ensuring smooth page-turning.

· Photo Books: Used for premium photo books to create a seamless and visually appealing finish with strong binding.

2. Packaging Materials

· Rigid Boxes: PUR laminating ensures a strong bond between decorative printed layers and rigid substrates, making it ideal for luxury packaging.

· Labels and Stickers: Provides durability and resistance to environmental factors like moisture and heat.

3. Commercial Printing

· Catalogs and Brochures: Ensures high-quality finishes that withstand frequent handling.

· Posters and Signage: Laminated prints remain vivid and protected from fading or physical damage.

· Menus and Flyers: Laminated with PUR for durability in environments like restaurants where items may be exposed to spills and frequent use.

4. Specialty Products

· Point of Sale (POS) Displays: PUR laminating is used for creating durable and visually appealing displays.

· Maps: Enhances tear resistance and weatherproofing, making maps more robust for outdoor use.

5. Flexible Printed Materials

· Magazines: Offers flexibility and durability for publications requiring a high-quality finish.

· Greeting Cards: Adds a protective layer that enhances the tactile and visual appeal of cards.

6. Textile Printing Applications

· Fabric Binders: For lamination of printed fabric or paper to textiles used in promotional or decorative items.

7. Custom Applications

· Photographic Prints: PUR laminating provides a protective and polished finish for large-format or high-end photographic prints.

· Art Prints: Ensures archival quality, protecting artwork from moisture, UV rays, and wear.

Advantages in the Printing Industry

· Durability: Resistant to moisture, heat, and wear, making products more robust.

· Flexibility: Ideal for applications requiring bendable or foldable outputs without cracking.

· Versatility: Compatible with a wide range of substrates, including paper, plastic films, and fabric.

· High Bond Strength: Ensures strong adhesion even on challenging surfaces like coated papers or glossy prints.

PUR laminating machines play a crucial role in enhancing the aesthetic and functional qualities of printed materials, making them indispensable in modern printing operations.

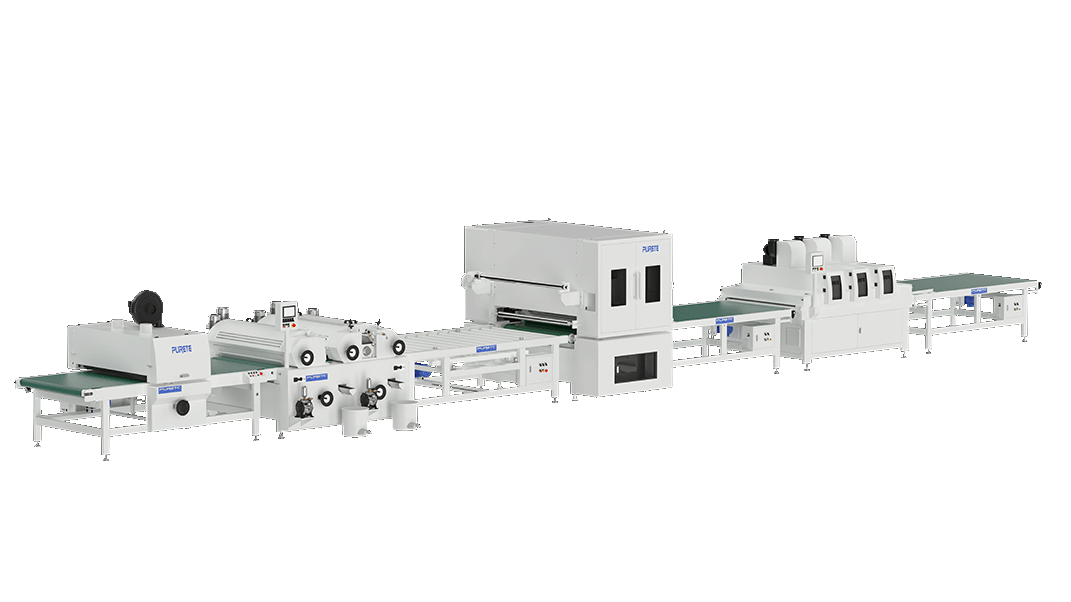

About Purete’s PUR Laminating Machines Line

Purete's PUR laminating machines are designed to meet the diverse needs of the printing industry, offering exceptional performance and reliability. These machines utilize advanced polyurethane reactive (PUR) adhesive technology, ensuring strong bonding, flexibility, and resistance to environmental factors like moisture, heat, and wear. With features such as precision control, high-speed operation, and compatibility with various substrates, Purete's laminating machines are ideal for applications ranging from bookbinding and packaging to commercial printing and specialty products. By choosing Purete's PUR laminating solutions, businesses can achieve superior quality and durability for their printed materials, enhancing both functionality and aesthetic appeal.