Key Features of Automatic Spray Painting Machine Systems

December 12, 2024

December 12, 2024 Hits:46second

Hits:46secondAutomatic spray painting machine systems are advanced solutions designed to enhance efficiency, consistency, and productivity in industrial coating processes. Below are the key features that make these systems essential for modern manufacturing and production lines:

1. Precision and Consistency

· Uniform Coating: Achieves a consistent paint thickness across all surfaces, regardless of shape or size.

· High Accuracy: Robotic arms or programmable sprayers apply paint with pinpoint precision, reducing overspray and waste.

2. Speed and Efficiency

· Fast Operation: Automates the painting process, significantly increasing production throughput.

· Reduced Downtime: Advanced systems are designed for continuous operation with minimal interruptions for maintenance.

3. Customizable Settings

· Adjustable Spray Patterns: Offers multiple spray patterns (fan, round, elliptical) to suit different applications.

· Programmable Parameters: Allows customization of spray angles, speed, and paint flow rate for varied products and surfaces.

4. Versatility

· Material Compatibility: Handles a variety of coatings, including water-based paints, solvent-based paints, and powder coatings.

· Application Flexibility: Suitable for a wide range of substrates like metal, plastic, wood, glass, and ceramics.

5. Advanced Automation and Control

· Robotic Integration: Features robotic arms or gantry systems for precise movement and complex painting tasks.

· Control Interfaces: Includes intuitive software for programming and monitoring the painting process in real time.

· IoT and AI Capabilities: Modern systems integrate with Industry 4.0 technologies for predictive maintenance and data analysis.

6. Environmental Compliance

· Reduced VOC Emissions: Designed to minimize volatile organic compound emissions, meeting stringent environmental regulations.

· Overspray Control: Incorporates efficient filters and exhaust systems to capture excess paint and reduce waste.

7. Cost-Effectiveness

· Material Savings: Minimizes paint wastage through precise application and controlled flow rates.

· Labor Reduction: Automation reduces the need for manual labor, lowering operating costs.

8. Safety Enhancements

· Reduced Human Exposure: Automates painting in hazardous environments, protecting workers from toxic fumes and chemicals.

· Fire and Explosion Prevention: Systems are equipped with safeguards for handling flammable materials.

9. Durability and Low Maintenance

· Robust Construction: Built with high-quality materials to withstand industrial wear and tear.

· Ease of Maintenance: Modular designs simplify cleaning, repairs, and part replacements.

10. Scalability

· Adaptability to Production Lines: Easily integrates into existing manufacturing processes.

· Expandable Systems: Configurations can be scaled up or down based on production volume and needs.

The key features of automatic spray painting machine systems highlight their ability to streamline operations, improve product quality, and ensure environmental sustainability. These systems are indispensable for industries aiming to optimize their coating processes while maintaining cost efficiency and safety standards.

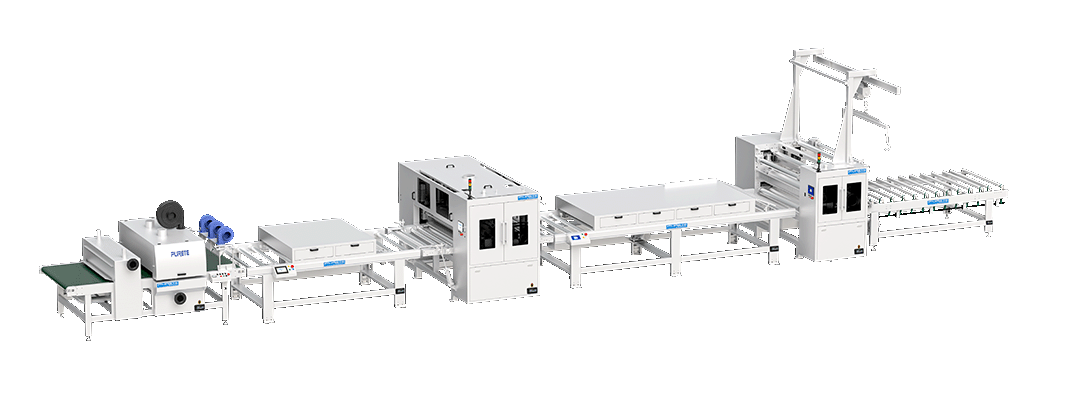

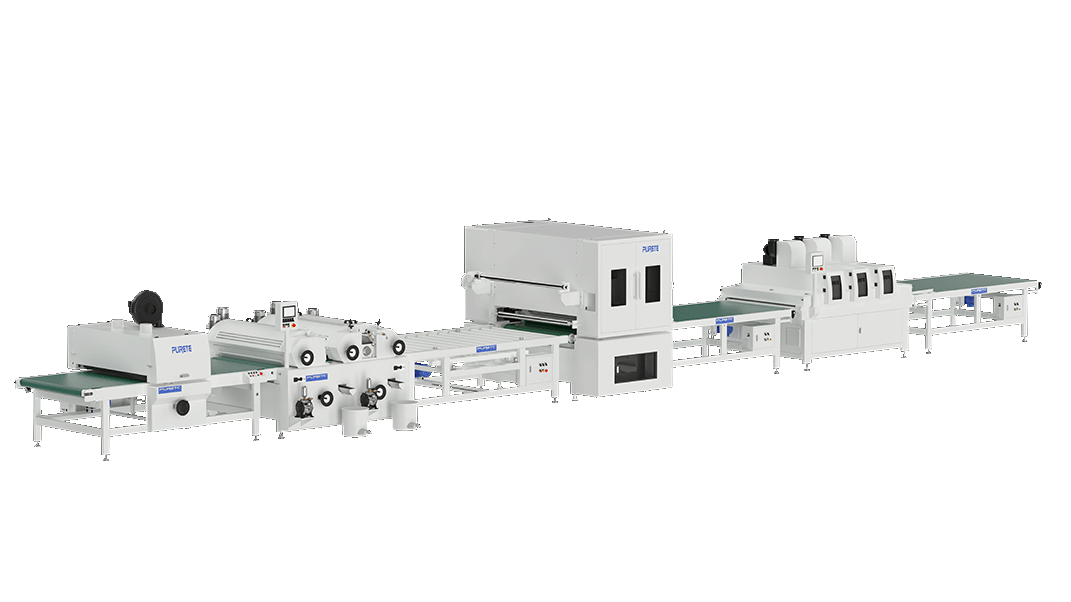

About Purete’s Spray Painting Machine Line

Purete specializes in advanced spray painting machine lines that provide high-quality, efficient, and sustainable painting solutions. Their lines integrate cutting-edge technology such as automated robotic arms, electrostatic spray systems, and precision controls that deliver exceptional consistency and minimal waste. Each system is designed to enhance productivity, reduce environmental impact, and meet strict quality standards. Whether for complex industrial applications or high-volume production, Purete's spray painting machine lines offer a customized solution that adapts to diverse manufacturing needs, ensuring reliable, high-quality finishes every time.