What is the purpose of a coating machine?

December 11, 2024

December 11, 2024 Hits:48second

Hits:48secondA coating machine is a specialized piece of equipment designed to apply a layer of material, often in the form of liquid, powder, or film, onto a substrate or surface. The purpose of a coating machine varies depending on the application and industry, but its primary goals typically include the following:

1. Surface Protection

· Purpose: To protect the substrate from environmental factors such as moisture, corrosion, UV radiation, and physical wear.

· Applications: Anti-corrosion coatings for metals, protective films for electronics, and moisture barriers in packaging materials.

2. Enhancing Appearance

· Purpose: To improve the aesthetic qualities of a product by adding color, gloss, or texture.

· Applications: Paint coatings for automobiles, decorative coatings for consumer goods, and finishes for furniture.

3. Functional Properties

· Purpose: To provide specific functional properties to a surface.

· Applications:

o Anti-reflective coatings for optical lenses.

o Conductive coatings for electronics.

o Non-stick coatings for cookware.

4. Improving Durability

· Purpose: To increase the lifespan and performance of a product by making it more resistant to wear, chemicals, or extreme conditions.

· Applications: Industrial tools, medical devices, and automotive components.

5. Efficiency and Performance in Manufacturing

· Purpose: To ensure uniformity and precision in the application of coatings, enhancing the quality and consistency of the end product.

· Applications: Film coating for pharmaceuticals, adhesive layers for laminates, and dielectric coatings for semiconductors.

6. Economic Benefits

· Purpose: To reduce waste and material costs by ensuring precise application and minimizing overcoating or defects.

· Applications: Roll-to-roll coating systems in packaging, spray coating for furniture, and vacuum deposition in electronics.

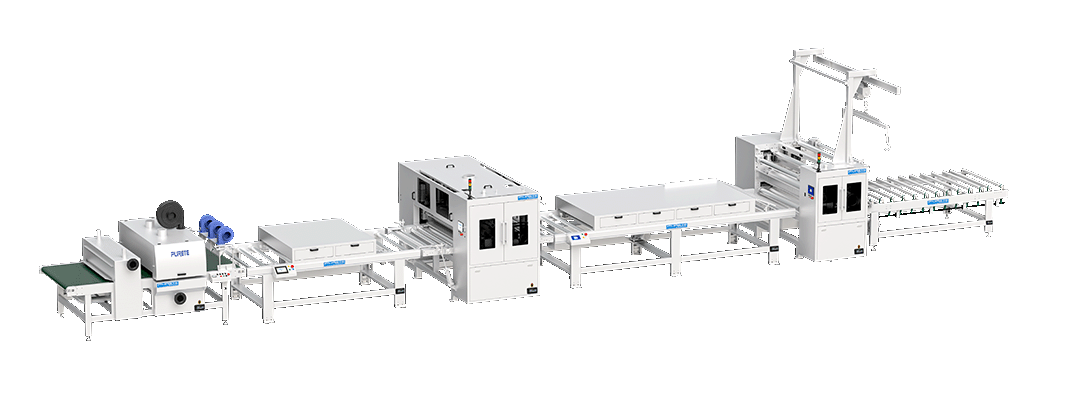

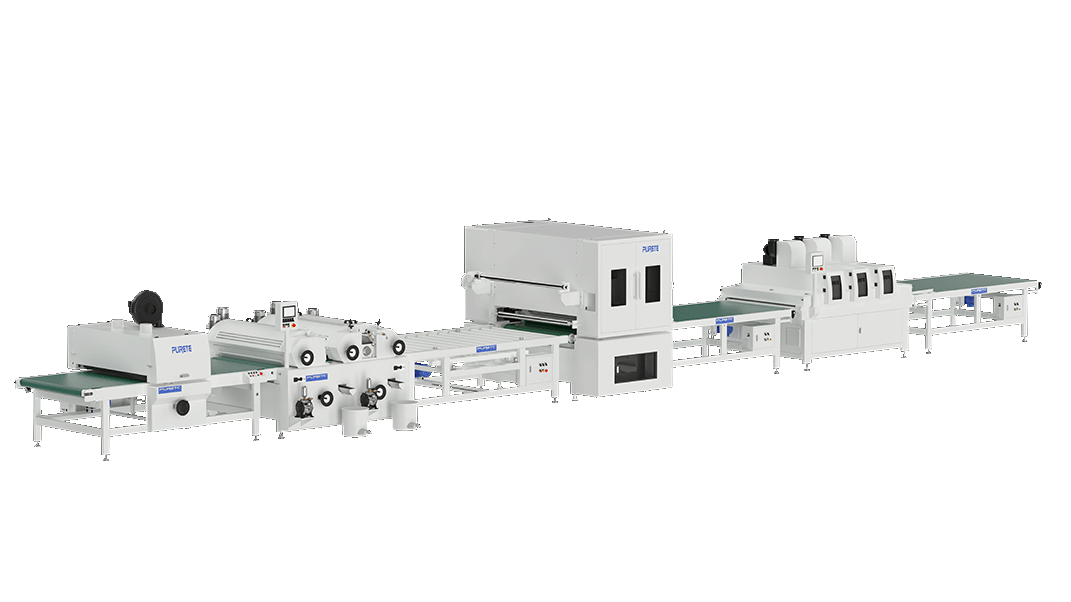

Common Types of Coating Machines

1. Roll Coating Machines: Used for applying coatings to flat surfaces, such as sheets or films.

2. Spray Coating Machines: Ideal for uneven or irregular surfaces.

3. Dip Coating Machines: Used when the entire surface needs uniform coverage.

4. Vacuum Coating Machines: For thin-film applications in industries like semiconductors and optics.

5. Curtain Coating Machines: Suitable for high-speed applications requiring precise thickness control.

Coating machines are essential across industries such as automotive, electronics, packaging, textiles, pharmaceuticals, and construction. Their versatility in applying various types of coatings makes them integral to modern manufacturing processes.