What is an Automatic Spray Painting Machine System?

December 06, 2024

December 06, 2024 Hits:242second

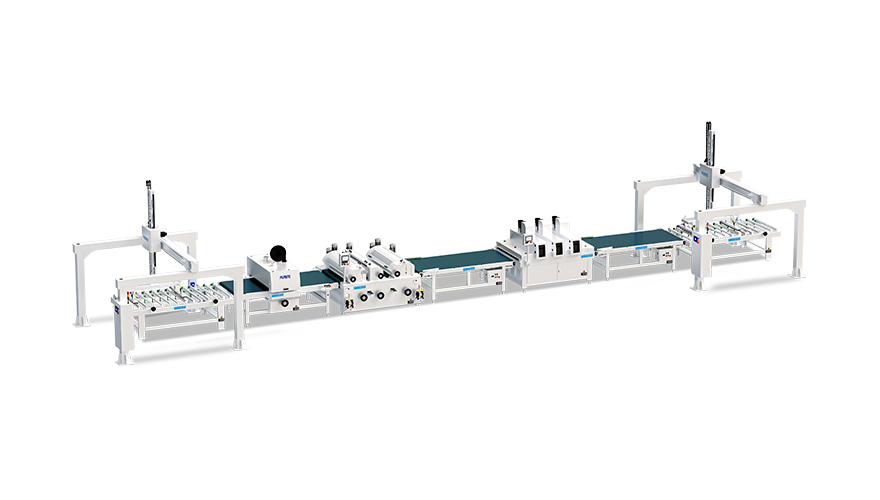

Hits:242secondAn Automatic Spray Painting MachineSystem is a mechanized solution designed to automate the process of applying paint or other coatings to surfaces in a consistent and efficient manner. These systems replace manual labor with advanced technology, ensuring high precision, uniform coverage, and reduced operational costs across various industries.

Core Components of an Automatic Spray Painting Machine System

Robotic Arms or Automated Sprayers

Equipped with spray nozzles, these units move with programmed precision to apply paint evenly over surfaces.

Conveyor Systems

Transport items through the painting process, synchronizing their movement with the sprayer for uninterrupted workflows.

Control Units

Programmable interfaces that allow customization of spray patterns, speeds, and paint thickness for different applications.

Spray Nozzles

Designed to atomize the paint into fine particles, ensuring smooth and even application.

Paint Delivery Systems

Pumps, reservoirs, or pressure systems that supply paint consistently to the sprayers.

Filters and Exhaust Systems

Reduce overspray and capture volatile organic compounds (VOCs) to ensure environmental compliance.

Key Features of an Automatic Spray Painting Machine System

· Precision: Guarantees uniform coating thickness and minimal wastage.

· Speed: Significantly faster than manual methods, increasing production efficiency.

· Versatility: Compatible with various paint types, including water-based, solvent-based, and powder coatings.

· Customization: Programmable settings to accommodate different shapes, sizes, and materials.

· Environmental Compliance: Designed to reduce paint waste and VOC emissions.

Applications of Automatic Spray Painting Machine Systems

Automatic spray painting machine systems are widely used in industries requiring high-quality surface finishes, such as:

· Automotive Manufacturing: Painting car bodies, bumpers, and accessories.

· Consumer Electronics: Coating device casings like laptops and phones.

· Furniture Production: Applying finishes to wooden and metal furniture.

· Aerospace Industry: Coating aircraft parts for protection and aerodynamics.

· Construction and Metalworking: Protecting pipes, machinery, and structural components.

Advantages of Automatic Spray Painting MachineSystems

1. Consistent Quality: Delivers a uniform finish regardless of surface shape or size.

2. Increased Efficiency: Speeds up the production process while maintaining quality.

3. Cost Savings: Reduces labor requirements and minimizes material waste.

4. Worker Safety: Limits human exposure to toxic fumes and hazardous environments.

5. Eco-Friendly: Advanced systems are designed to reduce overspray and environmental impact.

An Automatic Spray Painting MachineSystem is a transformative tool for industries aiming to enhance productivity, ensure consistent product quality, and reduce costs. Its integration into manufacturing and production lines marks a significant step toward automation, making it an indispensable asset in competitive industrial landscapes.