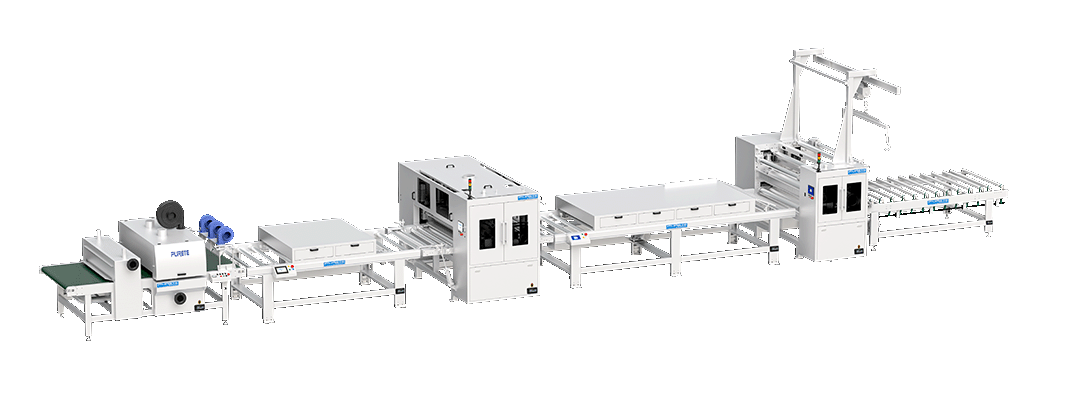

Guide to the PUR Laminating Machine Production Line

December 03, 2024

December 03, 2024 Hits:102second

Hits:102secondThe PUR laminating machine production line represents an advanced and efficient solution for bonding substrates with decorative materials using PUR (Polyurethane Reactive) glue. This guide provides a detailed overview of its process, components, and features, catering to industries such as furniture manufacturing, construction, and decoration.

Key Considerations in the Laminating Machine Line

When designing or operating a PUR laminating machine production line, it is crucial to consider several factors to achieve optimal results:

Glue:

PUR Glue is the adhesive of choice due to its strong bonding capability, flexibility, and durability. It offers excellent resistance to heat, moisture, and environmental conditions.

Panel Material:

Common substrates include melamine board, MDF, aluminum-plastic board, PVC board, gypsum board, calcium silicate board, glass magnesium board, honeycomb board, and metal board.

Decoration Material:

Roll Materials: PET, PETG, GAG, CPL, PVC, PP, paper, leather, aluminum foil, etc.

Sheet Materials: Acrylic, fireproof board, metal plates, etc.

Factory Environment:

A stable environment with controlled temperature and humidity is essential to ensure adhesive performance and avoid curing issues.

Laminating Process Flow

The PUR laminating process involves a sequence of precisely coordinated stages, ensuring a high-quality laminated product. Below is a detailed flow:

Loading Machine:

Feeds substrates into the production line efficiently and accurately.

Roller Conveyor with Alignment:

Aligns substrates for precise processing and reduces material wastage.

Chamfering Machine:

Prepares and smooths the edges of the substrates for seamless lamination.

Sanding Machine:

Provides a smooth surface by removing imperfections, enhancing glue adhesion.

Roller Conveyor:

Transfers substrates between processing stations seamlessly.

Two-Sided Cleaning Machine:

Removes dust and debris from both sides of the substrate, ensuring a clean surface for lamination.

IR Pre-Heating Machine:

Uses infrared heating for pre-warming substrates, improving glue activation and bonding.

PUR Glue Spreader:

Evenly applies PUR glue to the substrate surface with adjustable thickness control.

Sheet Lamination Operation Table:

Facilitates manual or automatic placement of decorative materials onto glued substrates.

Laminating Machine:

Bonds decorative material to the substrate with options for single or double roller systems.

Roller Conveyor with Side Trimming:

Trims excess material from the sides for a clean, finished edge.

Film Cutting Machine:

Cuts decorative film rolls to precise dimensions for the substrate.

Short Side Trimming Machine:

Provides fine trimming for short substrate edges.

Flipping Machine:

Flips substrates for inspection or dual-sided lamination.

Downloading Machine:

Safely removes finished products from the line for packaging or further processing.

Key Components and Features

1. Conveying System

· Design: Welded machine frame ensures a stable and robust system.

· Optional Features: Includes double-faced dust removal and a fan to enhance cleanliness.

2. Dust Removal System

· Utilizes double-faced electrostatic and plasma-jet systems to remove fine dust particles, dirt, and static, ensuring a flawless bond.

3. Substrate Pre-Heating System

· Infrared Heating: Middle-infrared lamps (18 kW) provide instant heating, activated via energy-saving sensor switches.

· Optional dust removal attachment improves substrate preparation.

4. Laminating Machines

· Single Roller Laminating Machine:

Air Pressure Mode: Uses an air cylinder for pressing.

Hydraulic Pressure Mode: Delivers stable pressure up to 4 tons with precise temperature control.

· Double Roller Laminating Machine:

Features motor-controlled press rollers, Siemens motors, and hydraulic pressing for even pressure distribution.

Optional Accessories for Customization

Corona Device:

Enhances film surface adhesion for materials with dyne values below 36.

Protective Film Device:

Adds a protective layer for delicate materials like PVC or PP, ensuring durability.

Doctor Blade System and Wrapping Machine:

Ideal for corner wrapping applications, ensuring precise cladding.

Double Roll Film Device:

Allows faster film changes, improving production efficiency.

Frame Hoisting Device:

Provides flexibility for multi-position operations.

Loose Film Roller with Heating Lampshade:

Softens films to prevent wrinkling or cracking, especially in cold environments.

Automation Equipment (Optional)

To enhance productivity and reduce manual intervention, various automation solutions can be integrated into the production line:

1. Loading Machine: Automated substrate feeding.

2. Chamfering Machine: Prepares precise edges.

3. Roller Conveyor with Side Trimming: For clean, finished edges.

4. Flipping Machine: Automates substrate flipping for dual-sided lamination.

5. Short Side Trimming Machine: Provides accurate edge cuts.

Advantages of the PUR Laminating Machine Production Line

Enhanced Adhesion:

PUR glue ensures strong and durable bonds that withstand heat and moisture.

Wide Material Compatibility:

Supports various substrates and decorative materials, offering flexibility in applications.

Efficiency and Precision:

Advanced automation and precise controls reduce production time and errors.

Customizable Features:

Optional accessories and automation cater to specific production needs.

Eco-Friendly Operation:

Low VOC emissions make PUR glue an environmentally sustainable choice.

The PUR laminating machine production line is a sophisticated, high-performance solution for laminating applications across diverse industries. Its precision-engineered components, customizable features, and advanced automation options make it a reliable choice for businesses aiming to achieve superior lamination quality while optimizing efficiency. By considering the critical factors outlined and utilizing the optional equipment, manufacturers can tailor the production line to meet specific operational needs, ensuring a competitive edge in the market.

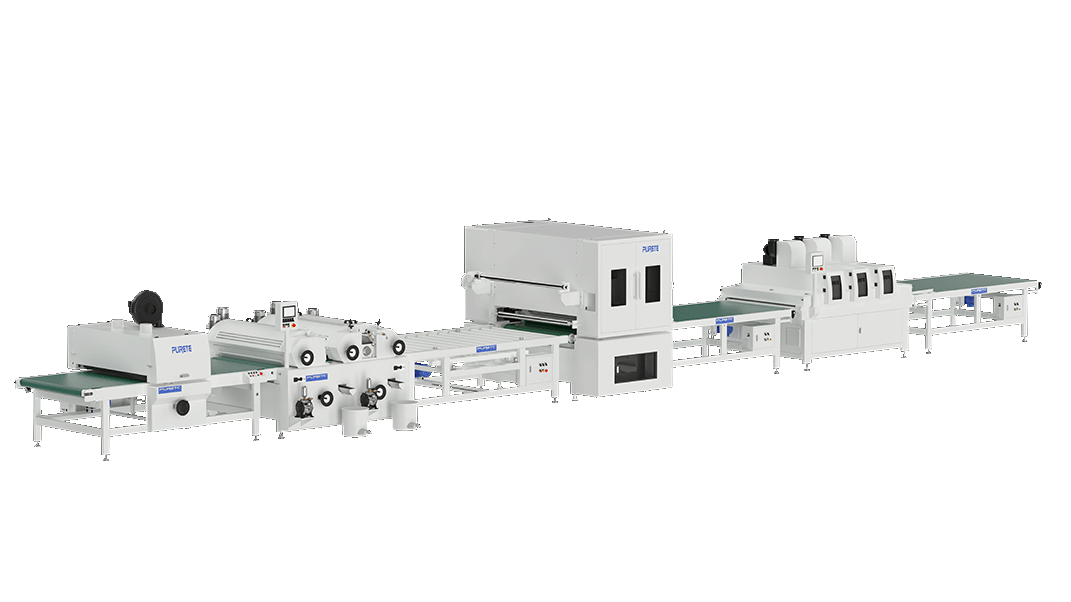

About Purete’s Spray Painting Machine Line

In addition to the PUR laminating production line, Purete also offers cutting-edge spray painting machine lines, designed to deliver exceptional surface finishing for a wide range of materials. These machines are engineered for high precision, uniform coating application, and enhanced productivity. Purete’s spray painting solutions cater to industries such as furniture, automotive, and electronics, ensuring smooth, flawless finishes with minimal overspray and waste.

Key features of Purete’s spray painting lines include:

· Advanced spray gun systems for precise and consistent application.

· High-efficiency drying systems to accelerate curing times and improve workflow.

· Customizable configurations to meet the specific needs of various substrates and coatings.

· Eco-friendly technology that minimizes emissions and supports sustainable operations.

By integrating Purete’s spray painting machines with laminating systems, manufacturers can achieve a seamless production process, delivering products with both superior aesthetic appeal and durable performance. Explore Purete’s comprehensive solutions to elevate your production standards to new heights.