What is a spray painting machine?

November 22, 2024

November 22, 2024 Hits:261second

Hits:261secondA spray machine, also known as a spray painting machine, is a device used to apply paint, coatings, or other liquids in a fine mist or spray. These machines are popular in industrial and commercial applications for painting surfaces quickly and evenly. Unlike traditional brush or roller methods, spray machines offer high efficiency and precision, making them ideal for covering large surfaces or applying thin, uniform coatings on intricate or irregularly shaped objects.

Key Components of a Spray Painting Machine

Spray painting machines generally include:

1. Pump or Compressor: Delivers the paint or coating through the system and builds the pressure needed to atomize the liquid.

2. Spray Gun: The handheld component that releases the coating as a fine mist. It includes a trigger mechanism to control the spray flow.

3. Nozzle: Determines the spray pattern and droplet size, adjustable to suit different applications.

4. Paint or Coating Container: Holds the liquid being sprayed, which may be attached directly to the spray gun or connected through a hose in larger systems.

Types of Spray Painting Machines

1. Airless Spray Machines: Use high pressure to atomize paint without the need for compressed air. These are powerful and ideal for large-scale applications, such as painting walls, fences, or industrial equipment.

2. HVLP (High Volume Low Pressure) Spray Machines: Use a high volume of air at low pressure to create a softer spray, resulting in minimal overspray. HVLP machines are often used in automotive, woodworking, and other applications where precision and finish quality are crucial.

3. Compressed Air Sprayers: Use compressed air to atomize paint. These are commonly used for smaller projects and can achieve a very smooth finish.

4. Electrostatic Sprayers: Charge the paint particles, allowing them to wrap around the surface evenly. This type is often used in industrial applications, especially for painting metal objects.

Applications of Spray Painting Machines

Spray machines are widely used in:

· Automotive Industry: For painting car bodies, parts, and accessories.

· Construction and Building: To apply paints or protective coatings on walls, ceilings, and other surfaces.

· Woodworking: For finishing furniture and other wood products.

· Industrial Coating: To protect equipment, machinery, and structural components.

· Consumer Goods: For coating appliances, electronics, and other products that require an even and consistent finish.

Benefits of Spray Painting Machines

· Efficiency: Cover large areas quickly.

· Uniform Coverage: Ensures smooth, even layers of paint.

· Versatility: Accommodates different paint types and finishes.

· Precision: Adjustable settings allow for control over spray pattern and pressure, suitable for various surfaces and textures.

Spray painting machines are essential in industries requiring efficient and high-quality coating processes and have numerous settings and types tailored to specific needs and finishing standards.

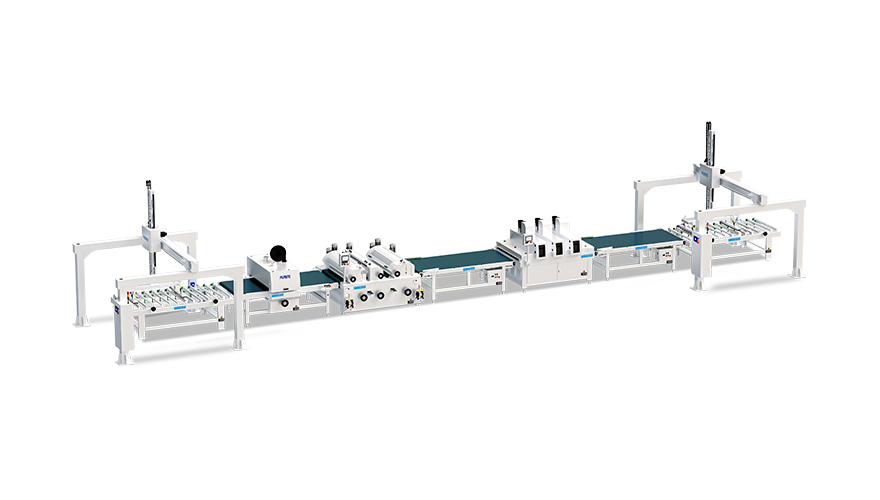

About Purete’s Spray Painting Machine Line

Purete specializes in advanced spray painting machine lines that provide high-quality, efficient, and sustainable painting solutions. Their lines integrate cutting-edge technology such as automated robotic arms, electrostatic spray systems, and precision controls that deliver exceptional consistency and minimal waste. Each system is designed to enhance productivity, reduce environmental impact, and meet strict quality standards. Whether for complex industrial applications or high-volume production, Purete's spray painting machine lines offer a customized solution that adapts to diverse manufacturing needs, ensuring reliable, high-quality finishes every time.