What is a coating machine?

December 10, 2024

December 10, 2024 Hits:48second

Hits:48secondA coating machine is a type of industrial equipment designed to apply a specific layer of material—such as liquid, powder, or film—onto a substrate or surface. This process can serve a variety of purposes, including protection, decoration, or functionality, depending on the material being coated and the industry where it's used.

Key Features of Coating Machines

1. Substrate Compatibility: Can work with various substrates, such as metal, plastic, fabric, paper, glass, or film.

2. Material Flexibility: Designed to apply different types of coatings, including paints, adhesives, powders, or films.

3. Application Methods: Incorporates techniques like spraying, rolling, dipping, or vacuum deposition to ensure a uniform layer.

How Coating Machines Work

The machine typically consists of a mechanism to feed the substrate, a coating application unit, and a drying or curing system. For example:

· The substrate is moved through the machine.

· The coating is applied via rollers, sprays, or dipping mechanisms.

· Excess material is removed, and the coating is dried, hardened, or cured to adhere properly to the surface.

Types of Coating Machines

1. Roll Coaters: Use rollers to apply coatings to flat or cylindrical surfaces.

2. Spray Coaters: Use nozzles to spray coatings evenly onto irregular or complex shapes.

3. Dip Coaters: Immerse the substrate into a coating liquid for uniform coverage.

4. Curtain Coaters: Create a flowing curtain of liquid coating that the substrate passes through.

5. Vacuum Coaters: Use vacuum deposition techniques to apply thin films for high-precision applications.

6. Powder Coating Machines: Apply a dry powder, followed by heating to create a durable finish.

Applications of Coating Machines

· Automotive: For painting car bodies and protective undercoatings.

· Electronics: For insulating or conductive coatings on circuit boards.

· Packaging: For applying protective or decorative coatings on paper, plastic, or metal.

· Pharmaceuticals: For coating tablets to control drug release or improve appearance.

· Textiles: For water-repellent or fire-resistant coatings.

· Optics: For anti-reflective or scratch-resistant coatings on lenses.

Benefits of Coating Machines

· Uniformity: Ensures even application of coatings for consistent quality.

· Efficiency: Automates the coating process, reducing labor and material waste.

· Customization: Can be adapted for specific materials, thicknesses, or finishes.

In summary, a coating machine is an essential tool in modern manufacturing, enhancing product durability, aesthetics, and performance across diverse industries.

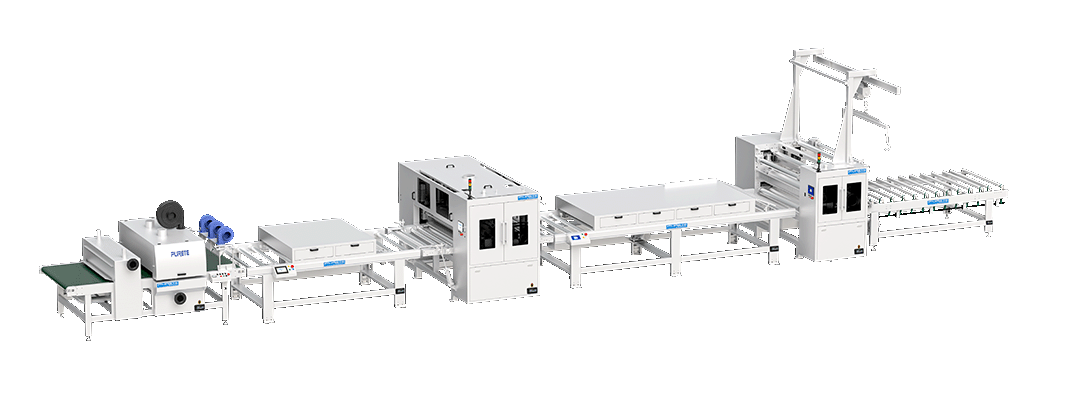

About Purete’s Coating Machine Line

Purete specializes in advanced Coating machine lines that provide high-quality, efficient, and sustainable painting solutions. Their lines integrate cutting-edge technology such as automated robotic arms, electrostatic Coating systems, and precision controls that deliver exceptional consistency and minimal waste. Each system is designed to enhance productivity, reduce environmental impact, and meet strict quality standards. Whether for complex industrial applications or high-volume production, Purete's Coating machine lines offer a customized solution that adapts to diverse manufacturing needs, ensuring reliable, high-quality finishes every time.