Roll Coating: A Modern Approach to Industrial Coating Processes

October 12, 2024

October 12, 2024 Hits:231second

Hits:231secondIn the field of industrial manufacturing, the pursuit of efficiency and precision has always been paramount. Roll coating, a technique that has gained significant popularity in recent years, offers a solution that combines these two crucial aspects of production.

What is Roll Coating?

Roll coating is a method in which a rotating roller transfers a liquid coating onto a substrate. This process can handle a wide range of viscosities and is particularly favored for its ability to apply coatings uniformly and consistently over large surface areas, such as metal sheets, plastic films, flooring, wood panels, and textiles.

Advantages of Roll Coating

· High Efficiency: The roll coating process is highly automated and offers rapid production speeds, sometimes reaching up to 244 meters per minute.

· Consistency: Roll coating ensures a uniform thickness of the coating, which is critical for maintaining quality control during production.

· Versatility: It can accommodate various types of coatings, from low to high viscosity, making it suitable for both thin and thick film applications.

· Environmental Friendliness: Compared to other coating methods, roll coating is more material-efficient, reducing the emission of volatile organic compounds (VOCs).

Applications of Roll Coating

Roll coating can be applied across a wide range of industries, including:

· Automotive: For coating automotive parts and exteriors.

· Electronics: Used to apply conductive and protective coatings on circuit boards and components.

· Packaging: Coating packaging materials to enhance barrier properties or provide specific surface effects.

· Textiles: Used to finish fabrics, altering texture, color, or waterproof properties.

· Construction: Applied to flooring, walls, furniture, wood panels, and more.

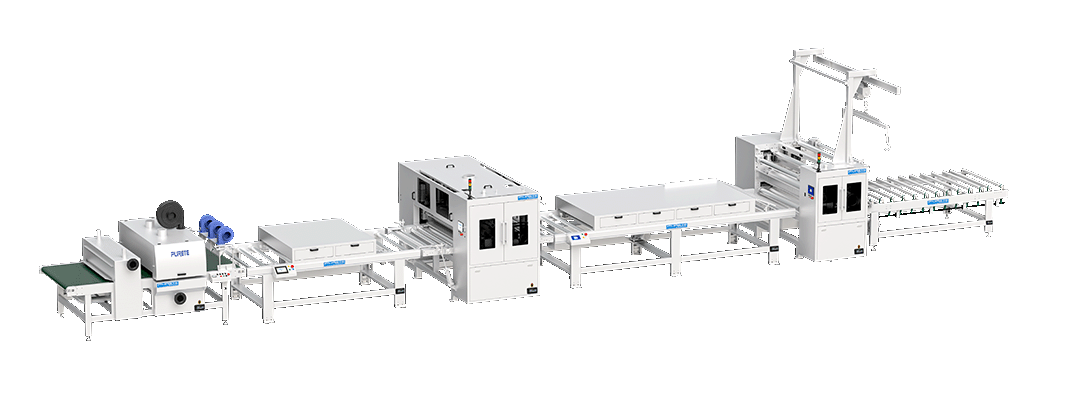

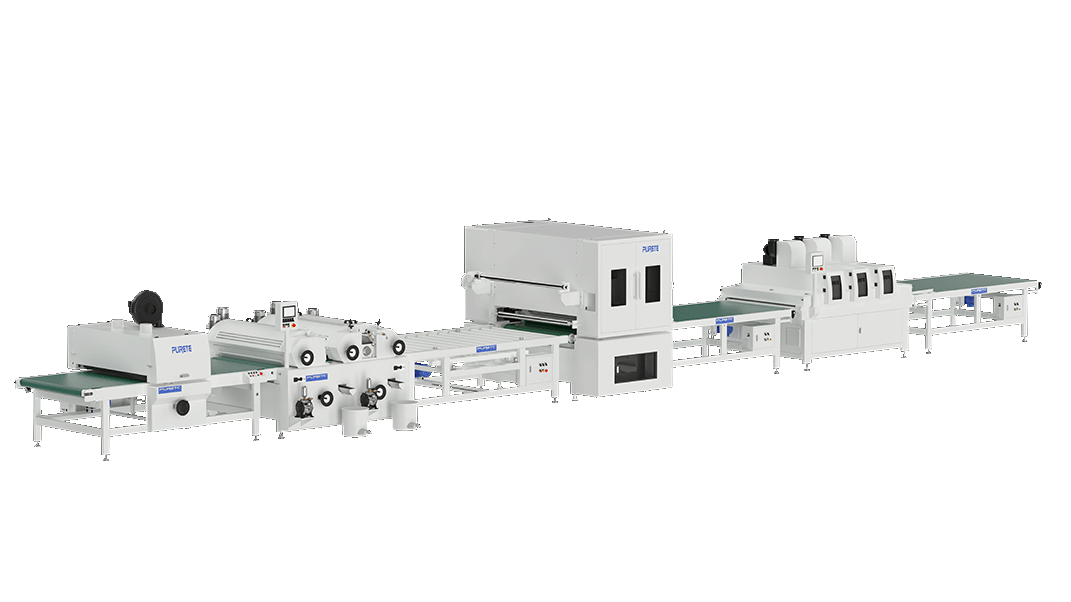

Integration with Modern Production Lines

The integration of roll coating technology into modern production lines has proven to be highly beneficial. Some common types of roller coating production lines and their advantages include:

· Multi-functional UV Coating Line

· Automatic Roller Coating Production Line

· Large Roller Coating Production Line

· Veneer Roller Coating Production Line

· Edge Banding Roller Coating Production Line

· SPC Floor Roller Coating Production Line

· Water-based High-speed Roller Coating Production Line

Key Features of Roller Coating Production Lines

· Customization: Each production line can be customized based on the specific coating materials and substrates used. Roller coating production lines can also be tailored to meet precise needs.

· Automation: Advanced control systems ensure that the production process is not only fast but also precise, minimizing the need for manual intervention.

· Quality Control: Online inspection systems monitor the coating process in real-time, detecting any deviations or defects.

· Sustainability: Production lines are designed to minimize waste and maximize the use of materials and energy.

As industries continue to evolve, the role of roll coating in production lines is expected to expand. With advancements in materials and technology, we can anticipate further improvements in the efficiency, precision, and sustainability of roll coating processes.

Roll coating is a testament to innovation in industrial manufacturing processes. Its integration into modern production lines signifies a shift towards more automated, efficient, and environmentally friendly production methods.