Features and Benefits of the Curtain Coating Line

October 23, 2024

October 23, 2024 Hits:175second

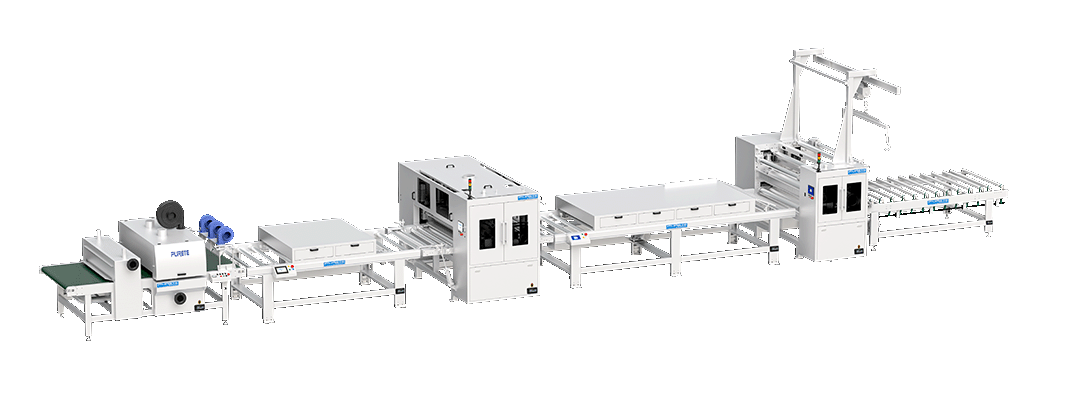

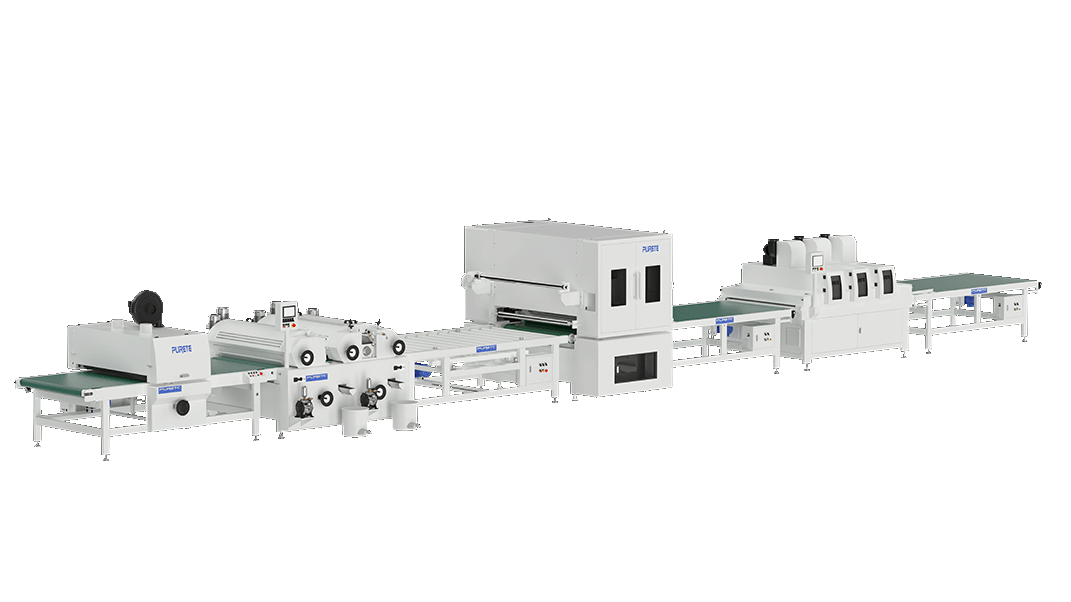

Hits:175secondCurtain Coating production lines are used for applying single or multi-layer functional coatings onto continuously running substrates. Here are some key features and advantages of Curtain Coating production lines:

Excellent Coating Uniformity: Curtain Coating technology can achieve excellent uniformity of the coated film in both machine direction (MD) and cross-web direction (CD), which is crucial for the quality of the coating.

High-Speed Production Capability: Curtain Coating production lines are capable of operating at speeds of 1000 meters per minute or higher, making them ideal for large-scale industrial applications typically found in the paper and pressure-sensitive adhesive (PSA) industries.

Multi-layer Coating Capability: The technology enables the application of multiple layers of coatings, which helps to optimize the functional performance of the product as well as the economics and technology of the production processes.

Scalability: The Curtain Coating process can be scaled up from research and development through pilot stages to full-scale production, demonstrating its good scalability and adaptability.

Cost-Effectiveness: By using Curtain Coating technology, it is possible to combine a relatively thick layer of expensive coating liquid with a part of inexpensive filling material and a second part of sophisticated coating liquid. This option is becoming increasingly attractive in the field of pressure-sensitive adhesive (PSA) labels to be more efficient in terms of raw material costs.

Environmental Friendliness: Curtain Coating machines offer precise control over coating thickness and minimize material waste, making them an environmentally friendly option. As industries worldwide strive for sustainable manufacturing processes, Curtain Coating production lines are welcomed for their environmental benefits.

Technological Innovation: There is a growing demand in the market for more advanced and efficient Curtain Coating production lines. Manufacturers are investing in research and development to create machines that offer greater precision, efficiency, and versatility.

Wide Range of Applications: Curtain Coating production lines are used across various industries, including furniture, automotive, electronics, and construction, highlighting their versatility and significant growth potential in the market.

Automation Trend: With the advancement of industrial automation, automatic Curtain Coating machines are becoming more popular due to their high efficiency, precision, and ability to handle large-scale operations. These machines are equipped with advanced sensors and control systems to ensure consistent and high-quality coating applications.

Regional Market Growth: The Asia Pacific region is expected to dominate the market for Curtain Coating machines, driven by rapid industrialization and urbanization in countries like China and India. The expansion of the furniture and construction industries in these regions also contributes to market growth.

These features and advantages of Curtain Coating production lines make them a new choice for efficient coating in many industries, and the market is expected to continue growing in the coming years.