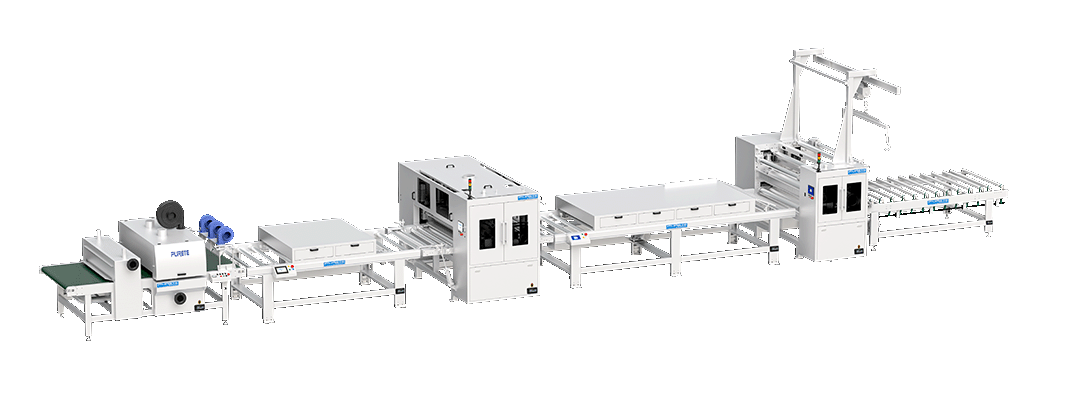

What is a curtain coating machine

October 29, 2024

October 29, 2024 Hits:163second

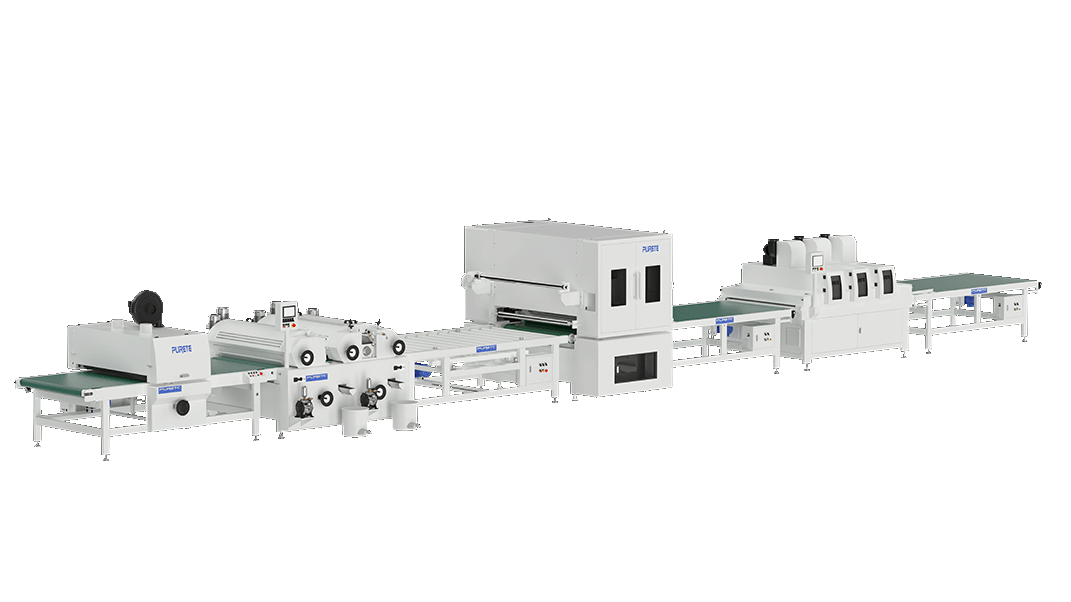

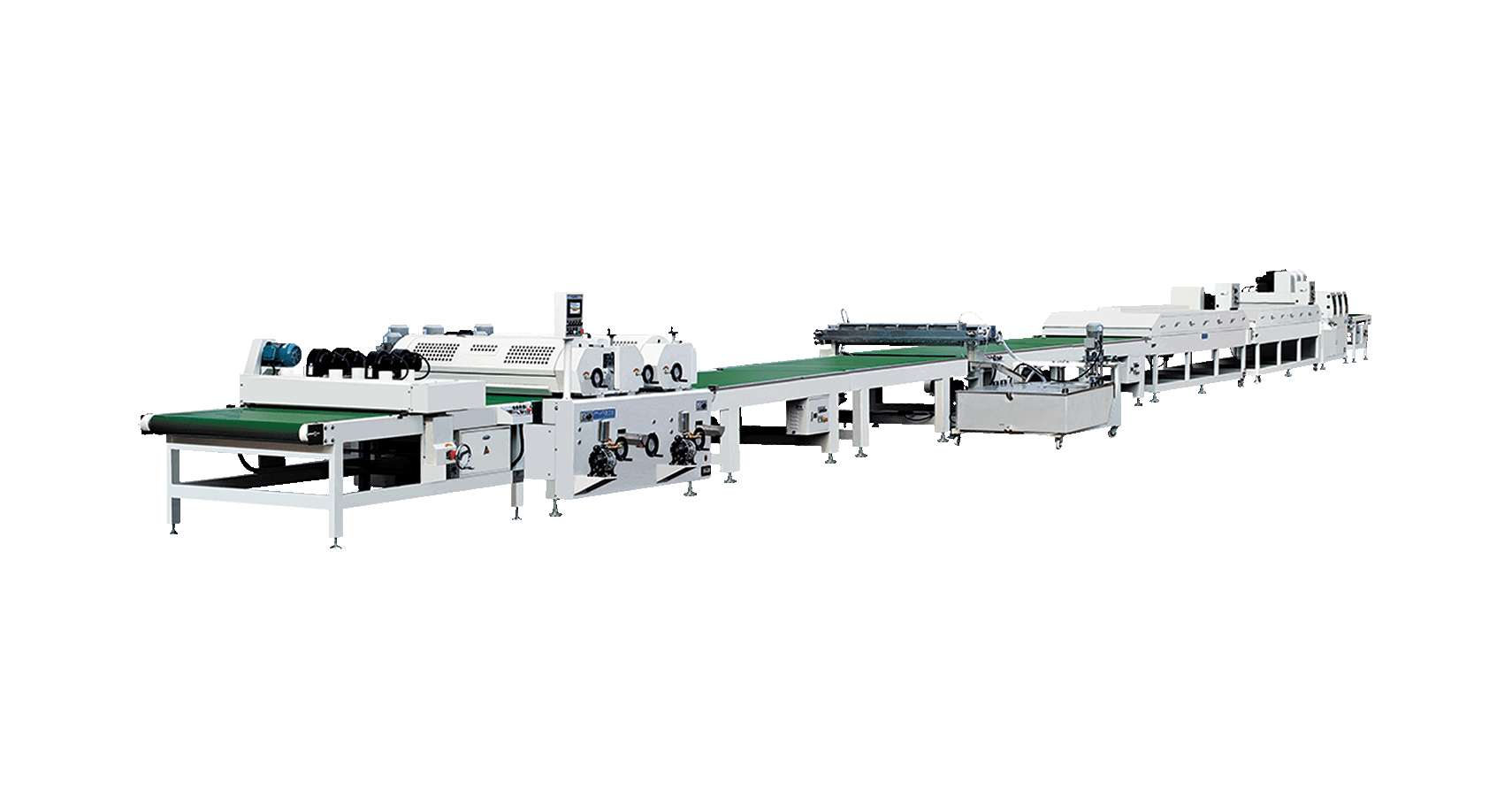

Hits:163secondCurtain coating machine is a type of equipment used to apply coatings onto a continuously moving substrate, such as paper, cardboard, metal sheets, plastic sheets, etc. The working principle of this machine involves a special device that creates a continuous "curtain" or "waterfall" of coating material that evenly falls onto the substrate, thus achieving the coating process. Here are some key features and applications of the curtain coating machine:

Working Principle:

The coating material flows out through a slot or a V-shaped groove, forming an even curtain that falls onto the substrate moving at a controlled speed. This coating method allows for the control of coating thickness and achieves uniform coating across the entire width of the substrate.

Multi-layer Coating:

Some curtain coating machines can apply multiple layers of coating simultaneously, with each layer being individually controlled. This provides the possibility of using functional coatings, such as thermal or barrier coating colors.

Uniformity and Quality:

Since the coating forms an even liquid curtain before coming into contact with the substrate, the integrity and coverage of the coating are virtually guaranteed. This technology is particularly suitable for applications that require uniform, pinhole-free coating layers, such as barrier coatings.

Flexibility and Versatility:

Curtain coating machines can work with various types of coatings, including water-based, polyurethane, and UV coatings, which can be clear or pigmented, and can achieve matte, semi-gloss, or glossy finishes. This technology can be used for various substrates, including wood, plastics, metals, ceramics, etc.

Efficiency and Cost:

Because of the coating method, the substrate can be produced with less or no white fibers at all. Each coating layer can be adjusted to the desired function and cost, which makes it possible to optimize the base paper and coating layer to achieve the most cost-effective solution.

Application Fields:

Curtain coating machines have a wide range of applications in various industries, including furniture manufacturing (such as drawers, flat doors), flooring (such as parquet), flat panels, indoor furniture, interior lining, and home furnishings.

Environmentally Friendly:

Since the unused coating can be recycled back into the system, this coating method wastes less paint than other methods and is more environmentally friendly.

High-speed Production:

Some systems can coat from 3,000 to 4,000 pieces per hour, indicating that curtain coating machines can be used for high-speed production.

In summary, the curtain coating machine is an efficient, flexible, and environmentally friendly coating equipment suitable for various substrates and coating requirements.