Revolutionizing the Industry with Unmanned Intelligent Coating Systems

September 11, 2024

September 11, 2024 Hits:249second

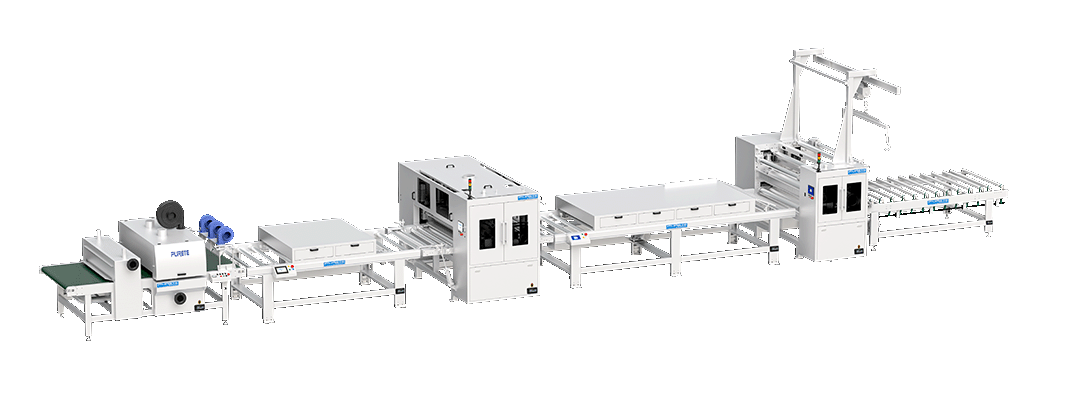

Hits:249secondIn the wave of industrial automation and intelligent manufacturing, the coating industry is undergoing a revolution. Traditional coating production lines are gradually being replaced by a new technology - the unmanned intelligent coating system. This system not only improves production efficiency but also ensures the consistency and diversity of coating quality.

Core Features of the Unmanned Coating System

The core of the unmanned intelligent coating system lies in its "unmanned" and "intelligent" characteristics. This system achieves full automation of the coating process through advanced automation technology and intelligent algorithms, without the need for human intervention. Here are some key features of the system:

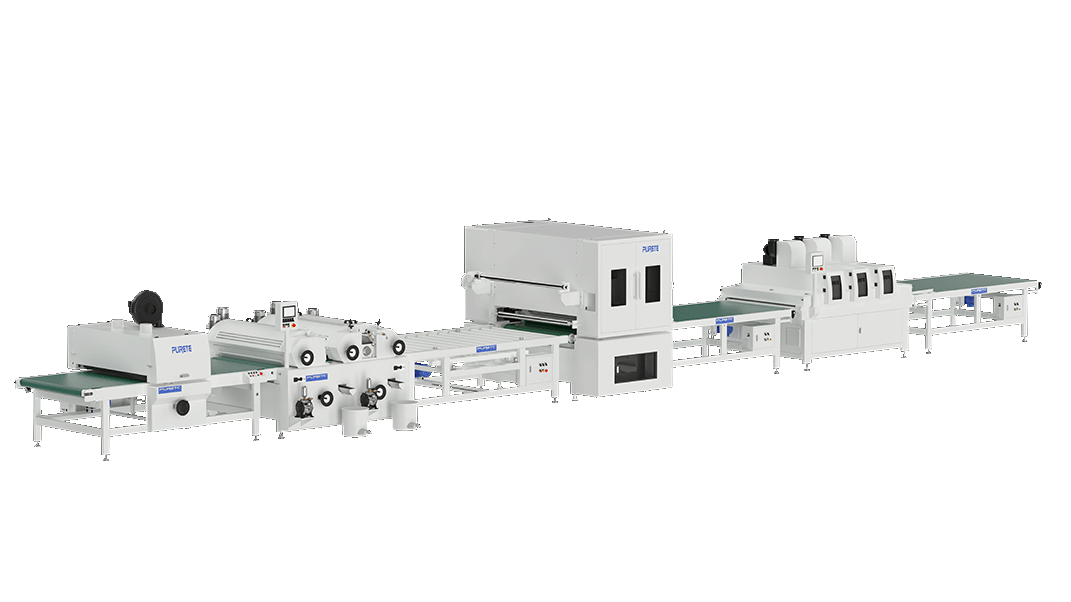

Flexibility (Flexible System):

The unmanned intelligent coating system can adapt to a variety of coating needs, whether it's solid color, transparency, skin touch effect, or high-gloss, all can be achieved on the same production line. This flexibility allows the production line to quickly switch between different coating processes, meeting the changing market demands.

Intelligence (Intelligent System):

The system's built-in intelligent algorithms can monitor the coating process in real-time, automatically adjusting parameters to ensure the best coating effect. The intelligent coating system can learn and optimize its operations, with performance continually improving over time.

Multi-process Online Processing

The unmanned intelligent coating system can handle multiple coating processes online simultaneously. This means that from primer to topcoat, to special effect coatings, all processes can be seamlessly connected on a single production line. This ability to process multiple processes online greatly shortens the production cycle and improves production efficiency.

Online Defect Detection and Automatic Sorting

Coating quality is an important indicator of the performance of a coating system. The unmanned intelligent coating system is equipped with online defect detection capabilities, able to detect any defects in the coating process in real-time. Once a problem is detected, the system automatically sorts the products into first-class, second-class, and defective products, ensuring that only products that meet quality standards enter the market.

Optimized Management through Data Monitoring System

Through an integrated data monitoring system, the unmanned intelligent coating system can provide detailed production data. Managers can view daily output, monthly output, annual output, equipment maintenance, and operation records at any time, thereby optimizing production planning and resource allocation. This transparency and traceability are crucial for improving production efficiency and product quality.

Industry Trend Insights and Production Optimization

The unmanned intelligent coating system also features a map board, a visual tool that displays the distribution of machine usage and industry data information. By analyzing this data, companies can gain the latest insights into industry trends and optimize production strategies accordingly. This open data sharing mechanism contributes to the progress and innovation of the entire industry.

The unmanned intelligent coating system represents the future of coating technology. With its unmanned and intelligent characteristics, it brings unprecedented efficiency and quality assurance to the coating industry. As technology continues to advance, there is reason to believe that this system will play an increasingly important role in future industrial production. It not only improves production efficiency but also drives continuous development and innovation in the entire industry through data analysis and intelligent optimization. As more and more companies adopt this system, we will usher in a new era of smarter, more efficient, and environmentally friendly coating.