Innovation and development of the Roller Coating production process

October 21, 2024

October 21, 2024 Hits:198second

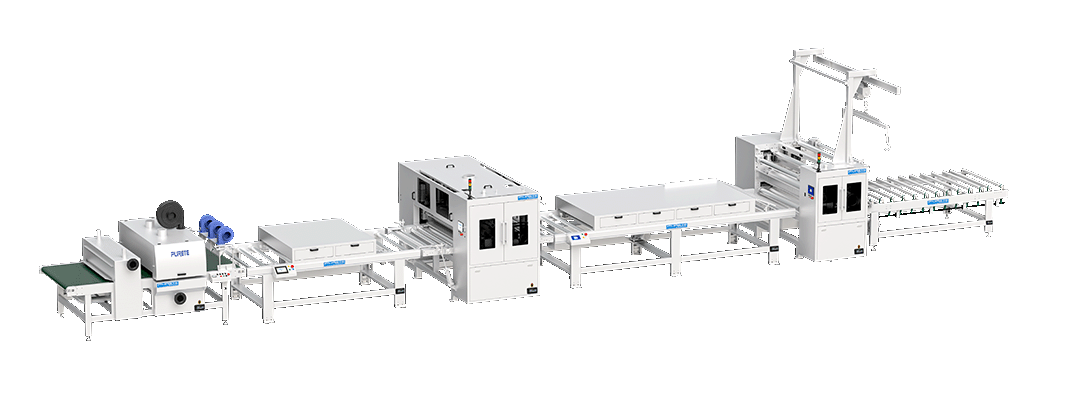

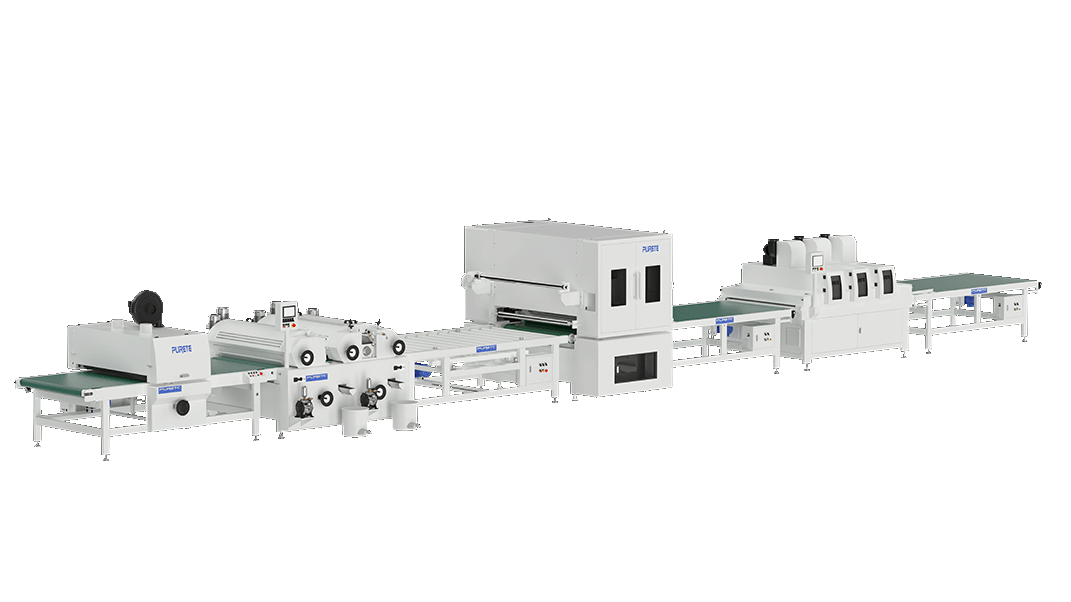

Hits:198secondRoller coating is an efficient coating technology that is widely used in industries such as furniture and building materials. Here is a discussion on the working principle, process, applications, innovative aspects, and future development trends of Roller coating production lines.

Working Principle and Process:

Roller coating production lines apply a uniform layer of coating to the surface of the substrate through rollers. By controlling the speed of the rollers and the supply of the coating, precise control of the coating can be achieved, ensuring uniform painting. This process typically includes steps such as coating supply, application, drying, and post-treatment. The high efficiency and uniformity of the production line give it a unique advantage in large-area painting.

Applications in Different Industries:

Furniture Industry: The application of roller coating technology in furniture manufacturing has attracted wide attention because it can provide a uniform coating, avoiding the unevenness that may occur in traditional painting. In addition, the roller coating process can paint very quickly, improving production efficiency, and can reduce the waste of paint, increasing the utilization rate of the coating.

Building Materials Industry: In the field of building materials, roller coating technology is often used for surface treatment of metal plates, such as the production of roller-coated plates. Roller-coated plates have advantages such as good temperature resistance, strong environmental protection, durability, and sturdiness. The metal plates processed by roller coating have a uniform and delicate color, soft and beautiful, and are not easy to have color difference.

Innovative Aspects of the Technology:

High Efficiency: Roller coating technology can achieve fast painting, greatly improving production efficiency.

Environmental Protection: Many roller coating processes are compatible with water-based paints, which helps to achieve green production.

Uniformity: Roller coating technology can ensure the uniformity of the coating, improving the appearance quality of the product.

Flexibility: The roller coating process can be applied to a variety of substrates, including solid wood, man-made panels, and metal materials.

Future Development Trends:

Technical Optimization: With the development of technology, roller coating technology will continue to be optimized to overcome challenges such as high equipment requirements and large initial investment.

Intelligentization: Roller coating production lines will likely become more automated and intelligent in the future to further improve efficiency and quality.

Environmental Protection Trend: The strengthening of environmental regulations will promote the development of roller coating technology in a more environmentally friendly direction, such as the application of water-based paints.

Personalized Customization: The controllability of roller coating technology makes it easier for coating customization, and there may be more personalized painting products in the future.

With the continuous advancement of manufacturing technology, roller coating technology is expected to play a more important role in the furniture manufacturing industry. Its efficient and environmentally friendly characteristics will meet the industry's pursuit of high quality.