How does a spray painting machine line work?

November 14, 2024

November 14, 2024 Hits:172second

Hits:172secondA spray painting machine line is designed to automate the painting process for various materials and components, improving efficiency, consistency, and quality. Here’s an overview of how a typical spray painting machine line works:

1. Pre-Treatment Stage

· Cleaning: Parts undergo a thorough cleaning process to remove dirt, grease, and other contaminants that could affect the paint’s adherence.

· Drying: After cleaning, the parts are dried to ensure that the paint will adhere properly.

· Surface Preparation: Depending on the material, parts may be primed or treated with chemicals to enhance paint adhesion.

2. Loading and Conveyor System

· Loading: Parts are placed onto a conveyor belt or suspended on an overhead system. This setup allows for continuous movement through each stage of the painting process.

· Conveyor System: The conveyor transports parts at a controlled speed, ensuring consistent exposure to each step in the line. Adjustable conveyor speeds enable customization for parts of different sizes and shapes.

3. Painting Stage

· Spray Guns and Atomizers: The core of the line, spray guns, and atomizers, apply paint to the parts. High-volume, low-pressure (HVLP) spray guns or electrostatic sprayers are commonly used for a smooth, even finish.

· Automated Robots: For precision, especially with complex parts, robotic arms or automated sprayers apply paint based on pre-programmed settings. These robots can adjust spray angles, patterns, and speeds to match each part’s requirements.

· Electrostatic Spray: This technique charges the paint particles, helping them adhere more evenly, which reduces overspray and waste. It also improves paint adhesion, especially on metals and plastics.

4. Drying and Curing Stage

· Initial Flash-Off Zone: After painting, parts move through a flash-off zone to allow solvents to evaporate, preventing imperfections in the finish.

· Drying Oven: Parts are transported into drying ovens, where they undergo heat treatment to cure the paint. This stage can include infrared or convection ovens, depending on the paint type and requirements.

· Cooling Zone: Once cured, parts pass through a cooling zone to bring them to a safe temperature before handling.

5. Inspection and Quality Control

· Visual Inspection: After cooling, trained personnel or automated systems visually inspect parts for any defects, such as uneven coating or blemishes.

· Automated Quality Control: Cameras and sensors can detect paint thickness and uniformity, ensuring each part meets quality standards.

6. Unloading and Packaging

· Unloading: Finished parts are removed from the conveyor for packaging.

· Packaging: Proper packaging ensures the parts are protected during transport. This may include protective wraps, padding, and securing materials.

Additional Features in Advanced Spray Painting Lines

· Closed-Loop Control: Advanced lines often use feedback mechanisms, where sensors monitor spray gun performance, paint flow, and conveyor speed, automatically adjusting to maintain consistent quality.

· Environmental Controls: Many modern lines include air filtration, recycling systems, and exhaust systems to reduce emissions and ensure a safe working environment.

Benefits of Automated Spray Painting Machine Lines

· Efficiency: Increased throughput as the automated system allows for faster, continuous operation.

· Quality Consistency: Uniform paint thickness and finish with reduced defects.

· Reduced Waste: Electrostatic spraying and precise control help minimize overspray and paint wastage.

· Safety: Reduced manual handling of paints and chemicals lowers risks associated with toxic fumes and spills.

In short, a spray painting machine line integrates cleaning, painting, drying, and quality control into a seamless, automated process, ensuring high-quality finishes on a wide range of materials.

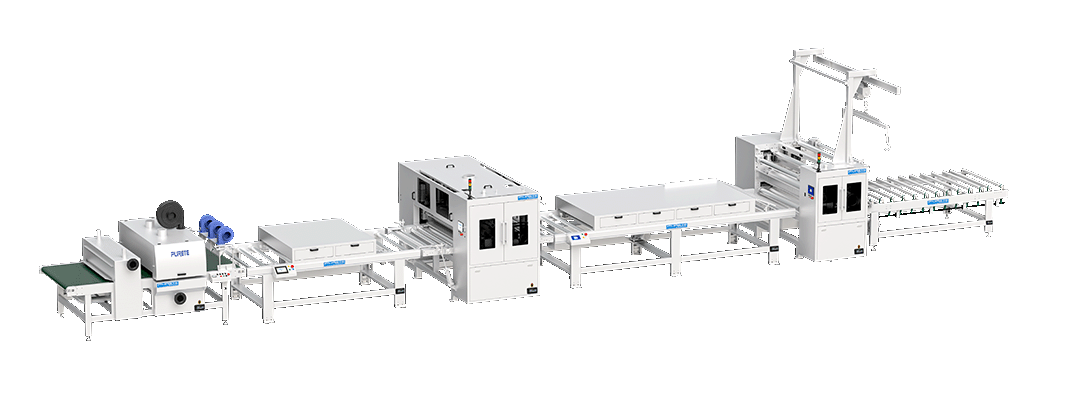

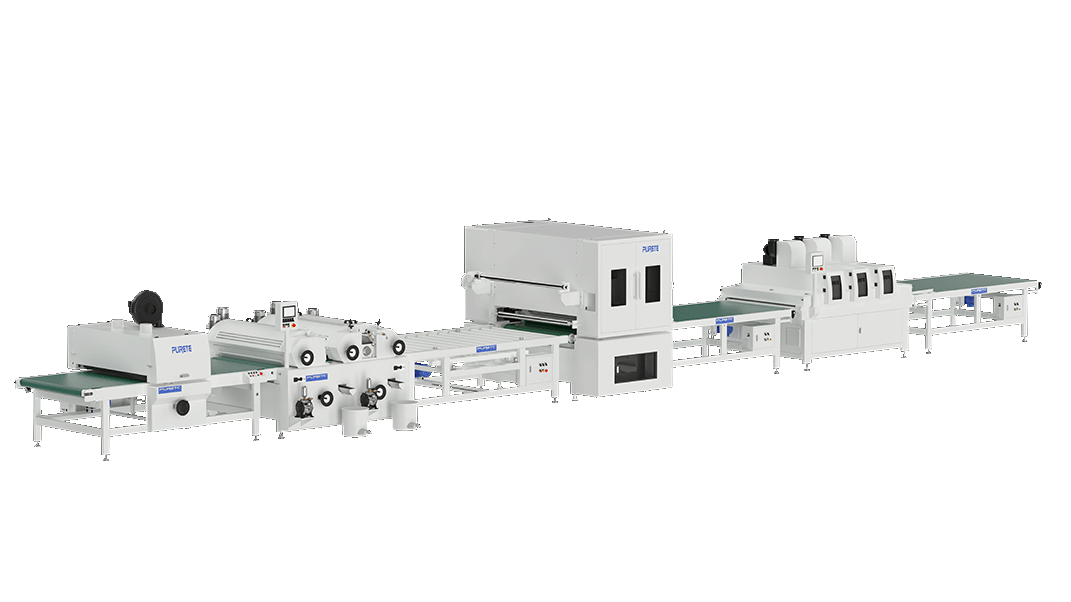

About Purete’s Spray Painting Machine Line

Purete specializes in advanced spray painting machine lines that provide high-quality, efficient, and sustainable painting solutions. Their lines integrate cutting-edge technology such as automated robotic arms, electrostatic spray systems, and precision controls that deliver exceptional consistency and minimal waste. Each system is designed to enhance productivity, reduce environmental impact, and meet strict quality standards. Whether for complex industrial applications or high-volume production, Purete's spray painting machine lines offer a customized solution that adapts to diverse manufacturing needs, ensuring reliable, high-quality finishes every time.

For more information about Purete's spray painting machine lines, visit Purete's website.