How does the PUR laminating process differ from other laminating methods?

December 23, 2024

December 23, 2024 Hits:184second

Hits:184secondThe PUR laminating machine process (Polyurethane Reactive) differs from other laminating methods primarily due to its adhesive properties, bonding mechanisms, and resulting durability. Below are the key differences that set PUR laminating machine apart from other common laminating methods such as EVA (Ethylene Vinyl Acetate), hot melt, or pressure-sensitive laminating:

1. Adhesive Type

· PUR: Utilizes a polyurethane reactive adhesive that chemically reacts with moisture in the air or substrate to form a strong, cross-linked bond.

· Other Methods:

o EVA: Uses thermoplastic adhesives that bond through cooling.

o Pressure-Sensitive: Relies on pre-applied adhesives that adhere under pressure without heat.

o Hot Melt: Similar to EVA but designed for lower-cost, simpler applications with less strength.

2. Bond Strength

· PUR: Offers superior bond strength due to the chemical cross-linking. It works well with difficult substrates like coated papers, glossy finishes, and synthetic materials.

· Other Methods: EVA and hot melt adhesives provide adequate bonds but are less effective on challenging or coated materials.

3. Heat Resistance

· PUR: Highly heat-resistant, maintaining its bond in high-temperature environments.

· Other Methods: EVA and hot melt adhesives are more sensitive to heat and may weaken or fail under high temperatures.

4. Flexibility

· PUR: Retains excellent flexibility after curing, making it ideal for products like softcover books, catalogs, and other items requiring bending or folding.

· Other Methods: EVA and hot melt adhesives can become brittle over time, leading to cracking along folds or spines.

5. Moisture Resistance

· PUR: Moisture-resistant after curing, ensuring durability in humid or wet conditions.

· Other Methods: EVA and hot melt adhesives are less resistant to moisture, making them unsuitable for certain environments.

6. Curing Process

· PUR: Requires a curing period for the adhesive to fully react and form its strongest bond, which can take several hours.

· Other Methods:

o EVA/Hot Melt: Bonds as the adhesive cools, resulting in shorter processing times.

o Pressure-Sensitive: Bonds instantly upon application.

7. Substrate Compatibility

· PUR: Works well with a wide range of substrates, including coated papers, plastics, textiles, and metals.

· Other Methods: EVA and pressure-sensitive adhesives are more limited in substrate compatibility.

8. Cost and Equipment

· PUR: Typically requires specialized equipment and is more expensive due to the adhesive and precision application requirements.

· Other Methods: EVA and hot melt systems are more cost-effective and simpler to operate but lack the durability and versatility of PUR.

Advantages of PUR Laminating Machines

· Strong and durable bond.

· Works with challenging materials.

· Flexible and resistant to cracking.

· Resistant to heat and moisture.

· Ideal for high-quality applications, including bookbinding, luxury packaging, and specialty printing.

Applications Best Suited for PUR

· Hardcover and softcover books.

· High-end packaging materials.

· Laminated prints and displays for humid or outdoor environments.

· Flexible materials requiring strong adhesion.

In summary, the PUR laminating machine process stands out for its durability, flexibility, and ability to bond challenging substrates, making it ideal for premium and demanding applications. While other methods like EVA or hot melt may suffice for less critical tasks, PUR is the preferred choice for industries requiring high-performance laminated products.

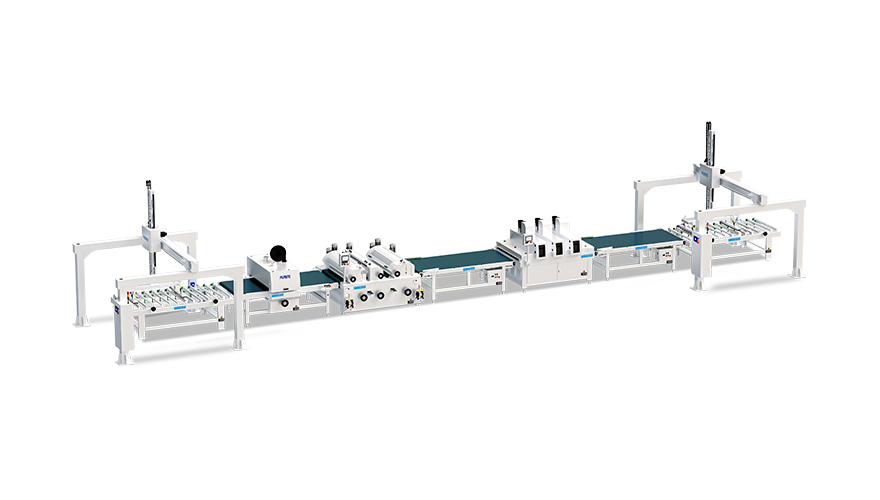

About Purete’s PUR Laminating Machines Line

Purete's PUR laminating machines are designed to meet the diverse needs of the printing industry, offering exceptional performance and reliability. These machines utilize advanced polyurethane reactive (PUR) adhesive technology, ensuring strong bonding, flexibility, and resistance to environmental factors like moisture, heat, and wear. With features such as precision control, high-speed operation, and compatibility with various substrates, Purete's laminating machines are ideal for applications ranging from bookbinding and packaging to commercial printing and specialty products. By choosing Purete's PUR laminating solutions, businesses can achieve superior quality and durability for their printed materials, enhancing both functionality and aesthetic appeal.