What is the Function of a Spray Painting Machine?

December 24, 2024

December 24, 2024 Hits:184second

Hits:184secondA spray painting machine is specifically designed to apply paint or coatings to surfaces efficiently, evenly, and with high precision. It automates the painting process, ensuring consistent coverage, reducing material waste, and enhancing productivity in various industrial, commercial, and residential applications.

Key Functions of a Spray Painting Machine

1. Uniform Application of Paint

· Purpose: Delivers paint evenly across surfaces, ensuring a smooth and consistent finish.

· Benefits: Eliminates brush marks and inconsistencies caused by manual application.

2. Atomization of Paint

· Purpose: Breaks the paint into fine droplets using high pressure, air, or electrostatic forces.

· Benefits: Creates a smooth and professional-quality finish, even on complex shapes.

3. Increased Efficiency

· Purpose: Automates the painting process, enabling faster application compared to manual methods.

· Benefits: Reduces time and labor costs while maintaining high-quality output.

4. Precision Painting

· Purpose: Targets specific areas with controlled spray patterns and adjustable settings.

· Benefits: Reduces overspray and ensures minimal paint wastage.

5. Versatility in Paint Types and Surfaces

· Purpose: Handles a wide range of paint types (water-based, solvent-based, or powder coatings) and surface materials (metal, wood, plastic, etc.).

· Benefits: Adapts to various industrial and decorative applications.

6. Environmental Efficiency

· Purpose: Minimizes paint waste and reduces volatile organic compound (VOC) emissions.

· Benefits: Supports environmentally sustainable practices and complies with regulations.

Applications of Spray Painting Machines

Automotive Industry

o Coats car bodies, parts, and accessories with precision and durability.

Consumer Goods

o Applies finishes to appliances, furniture, and electronic devices for a polished appearance.

Industrial Coatings

o Protects machinery, equipment, and structural components from corrosion and wear.

Construction and Infrastructure

o Used for painting walls, ceilings, and large-scale projects efficiently.

Aerospace Industry

o Coats aircraft components for protection and aesthetic purposes.

Art and Decorative Applications

o Enables artistic expression and design on various surfaces.

Benefits of Using a Spray Painting Machine

Quality Improvement

o Delivers a consistent and professional-quality finish.

Cost Savings

o Reduces labor and paint consumption through efficient application.

Safety

o Limits human exposure to paint fumes and hazardous chemicals.

Customization

o Adjustable settings cater to diverse requirements and finishes.

Scalability

o Suitable for both small-scale and high-volume painting tasks.

The function of a spray painting machine is to streamline the painting process by delivering precision, efficiency, and consistent quality. Its ability to handle diverse materials and applications makes it an invaluable tool in industries such as automotive, construction, and manufacturing. By investing in a spray painting machine, businesses can enhance productivity, reduce costs, and achieve superior finishes in their products.

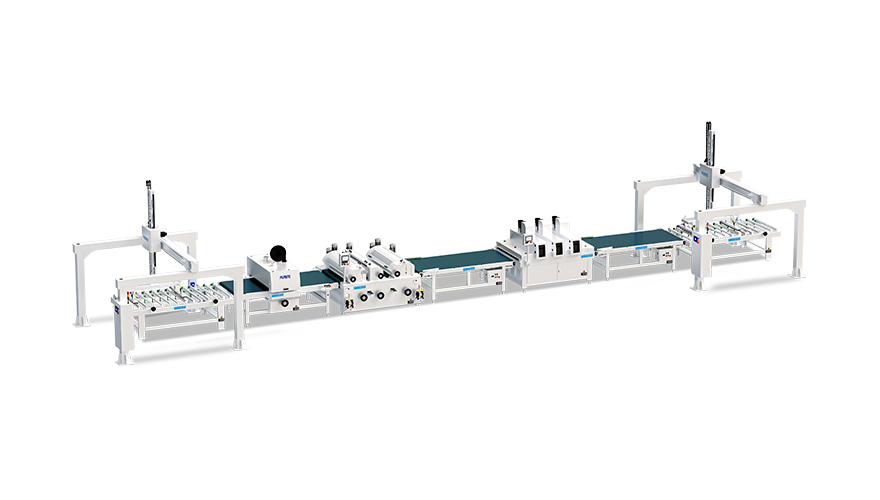

About Purete’s Spray Painting Machine Line

Purete specializes in advanced spray painting machine lines that provide high-quality, efficient, and sustainable painting solutions. Their lines integrate cutting-edge technology such as automated robotic arms, electrostatic spray systems, and precision controls that deliver exceptional consistency and minimal waste. Each system is designed to enhance productivity, reduce environmental impact, and meet strict quality standards. Whether for complex industrial applications or high-volume production, Purete's spray painting machine lines offer a customized solution that adapts to diverse manufacturing needs, ensuring reliable, high-quality finishes every time.