What is a Surface Finishing Machine?

February 18, 2025

February 18, 2025 Hits:140second

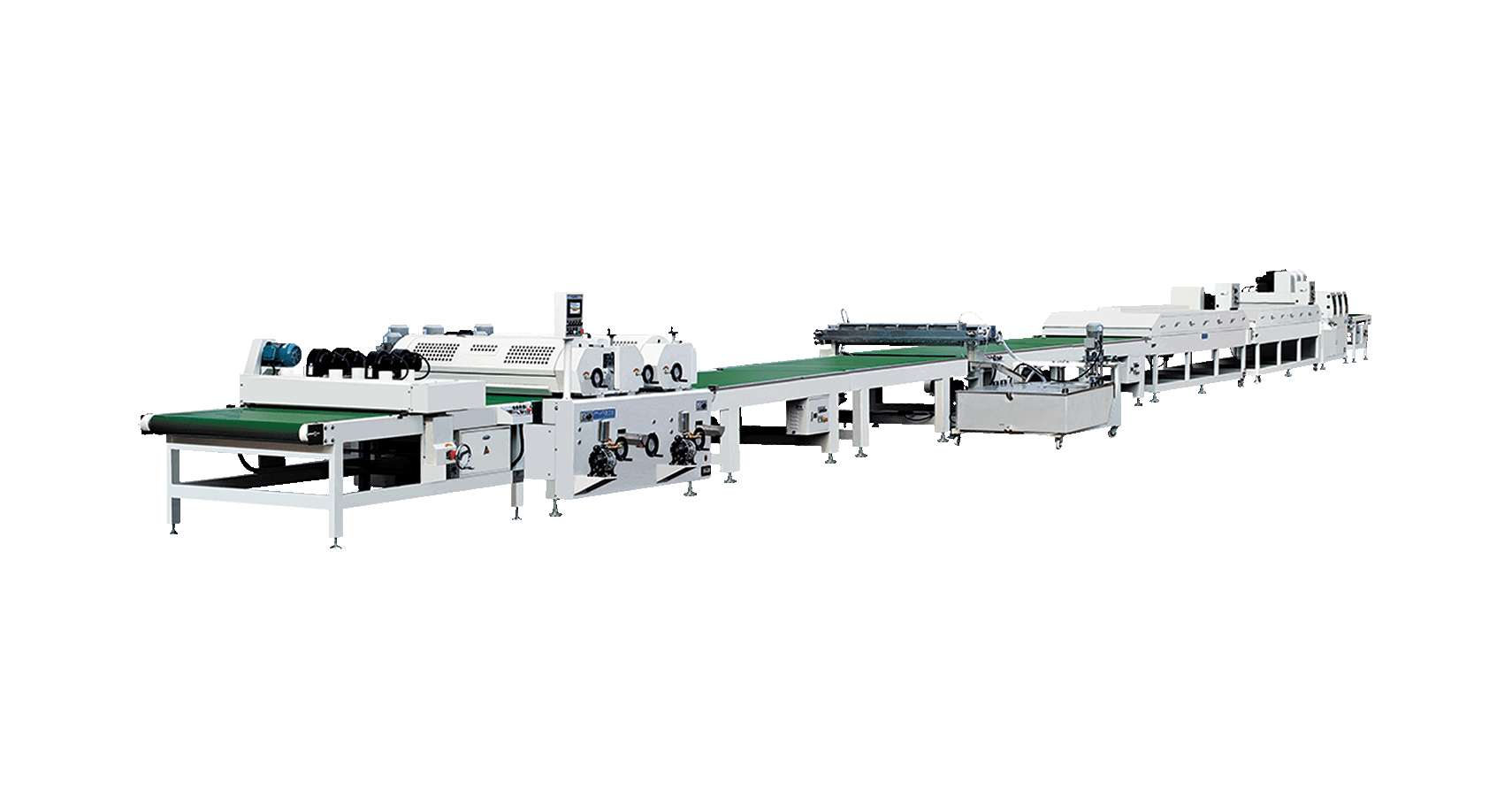

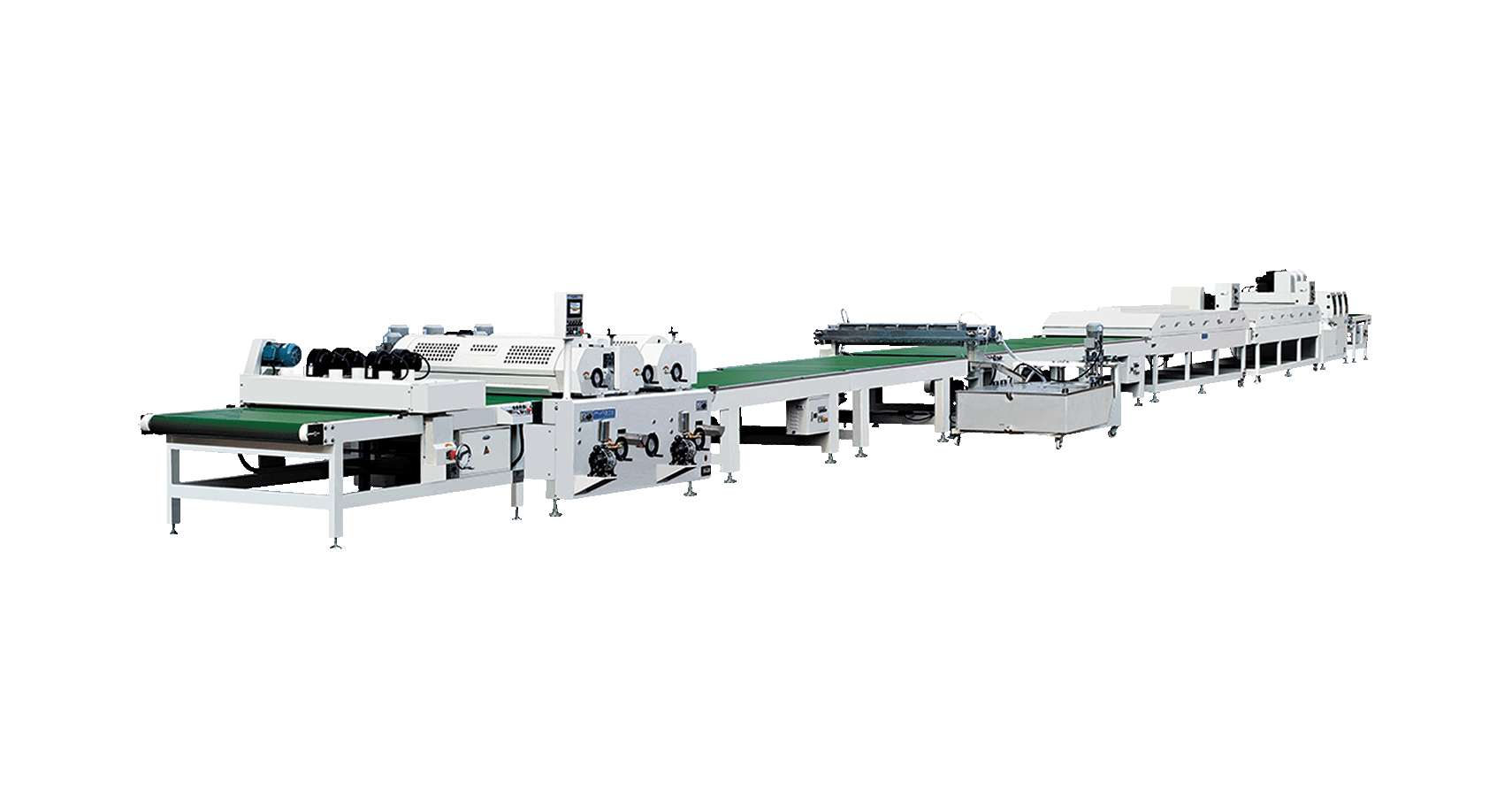

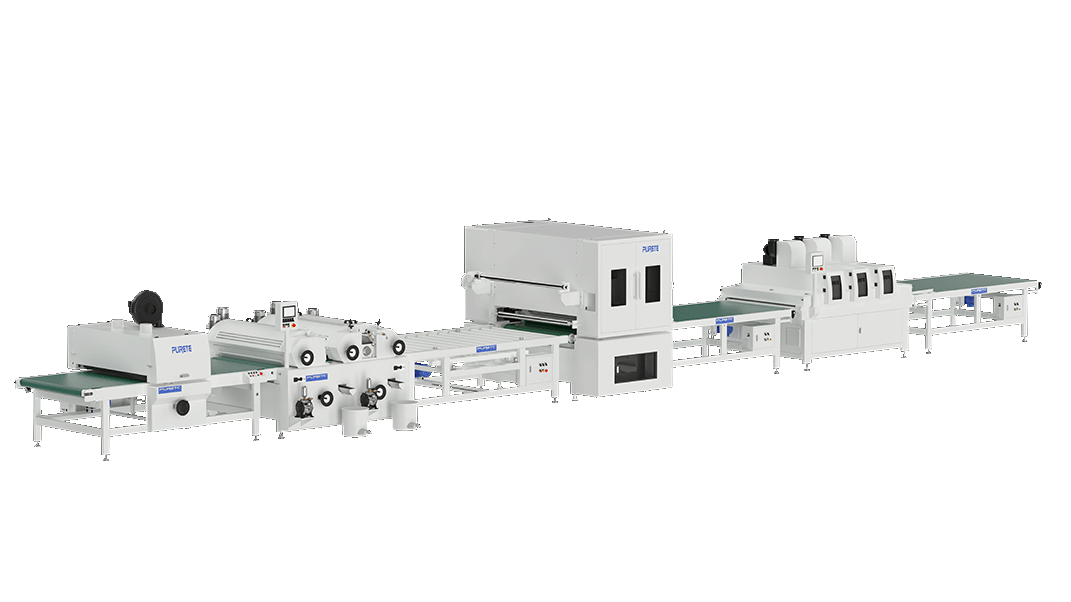

Hits:140secondA surface finishing machine is specialized equipment used to enhance the surface quality of a material by refining its texture, removing imperfections, and improving its overall appearance. These machines are widely used in industries such as automotive, aerospace, medical devices, metalworking, and construction. They play a crucial role in ensuring that products meet strict quality and aesthetic standards before reaching consumers.

The Purpose of Surface Finishing Machines

Surface finishing machines serve multiple purposes, including:

Deburring – Removing sharp edges, burrs, or excess material from manufactured components.

Polishing – Enhancing the smoothness and shine of a surface to improve aesthetics and functionality.

Grinding – Achieving precise material removal to meet specific dimensional tolerances.

Cleaning – Removing rust, oxidation, and contaminants from metal and non-metal surfaces.

Coating Preparation – Preparing surfaces for painting, plating, or other finishing processes by ensuring they are clean and smooth.

Types of Surface Finishing Machines

There are various types of surface finishing machines designed for different applications and materials. The most common types include:

1. Vibratory Finishing Machines

Used for mass finishing of parts by placing them in a bowl with abrasive media and compounds.

Ideal for deburring, polishing, and descaling metal and plastic components.

Efficient for high-volume production.

2. Buffing and Polishing Machines

Used to create a high-gloss finish on metals, plastics, and other materials.

Operate using rotating wheels covered with polishing compounds.

Common in jewelry making, automotive detailing, and stainless-steel finishing.

3. Grinding Machines

Used for precise material removal using abrasive wheels.

Essential in manufacturing industries requiring high-precision finishes.

Types include belt grinders, surface grinders, and cylindrical grinders.

4. Sandblasting Machines

Use high-pressure air to propel abrasive materials like sand, glass beads, or aluminum oxide.

Effective for removing rust, paint, and corrosion from metal surfaces.

Used in restoration, automotive repair, and industrial maintenance.

5. Electropolishing Machines

Utilize an electrochemical process to remove material and smooth metal surfaces.

Improve corrosion resistance and create a mirror-like finish.

Commonly used in medical, food processing, and aerospace industries.

6. Shot Peening Machines

Strengthen metal components by bombarding them with small metallic or ceramic shots.

Increase resistance to fatigue and stress-related failures.

Used in aerospace, automotive, and structural engineering applications.

Key Industries Using Surface Finishing Machines

Surface finishing machines are critical in numerous industries, including:

Automotive Industry: Used for finishing engine components, gears, and body panels.

Aerospace: Ensures high precision and durability for turbine blades, landing gears, and aircraft frames.

Medical Equipment: Provides smooth, hygienic surfaces for surgical instruments and implants.

Metal Fabrication: Improves the appearance and functionality of fabricated metal parts.

Electronics: Enhances the surface quality of semiconductors, circuit boards, and casings.

Benefits of Using Surface Finishing Machines

Improved Product Quality: Enhances appearance, durability, and performance of finished products.

Consistency and Precision: Ensures uniform surface treatment across large batches.

Enhanced Efficiency: Reduces manual labor and increases production speed.

Material Conservation: Minimizes waste and improves the sustainability of manufacturing.

Increased Longevity: Helps prevent corrosion, wear, and fatigue in metal components.

Choosing the Right Surface Finishing Machine

When selecting a surface finishing machine, consider:

Material Type: Different materials require different finishing techniques.

Surface Requirements: Define the required roughness, smoothness, or gloss level.

Production Volume: High-volume production may need automated or batch processing machines.

Cost and Budget: Balance between initial investment, operational cost, and long-term benefits.

Environmental Impact: Some finishing processes use chemicals or generate waste; consider eco-friendly options.

Future Trends in Surface Finishing

The surface finishing industry is evolving with innovations in automation, sustainability, and precision technology. Some emerging trends include:

Automation and Robotics: Increasing efficiency and consistency through robotic finishing solutions.

Eco-Friendly Techniques: Development of non-toxic, water-based, and energy-efficient finishing methods.

Advanced Coatings: Integration of nanotechnology for superior surface protection.

3D Printing Integration: Custom surface finishing solutions for additive manufacturing components.

Surface finishing machines are indispensable tools in modern manufacturing, providing critical improvements in quality, efficiency, and durability. With continuous advancements in technology, these machines are becoming more sophisticated, sustainable, and adaptable to industry needs. Whether in aerospace, automotive, medical, or general manufacturing, selecting the right surface finishing machine ensures high-quality end products and enhanced performance.