Innovative Material Applications in Soft-Touch (Excimer) Coating Production Lines

March 03, 2025

March 03, 2025 Hits:58second

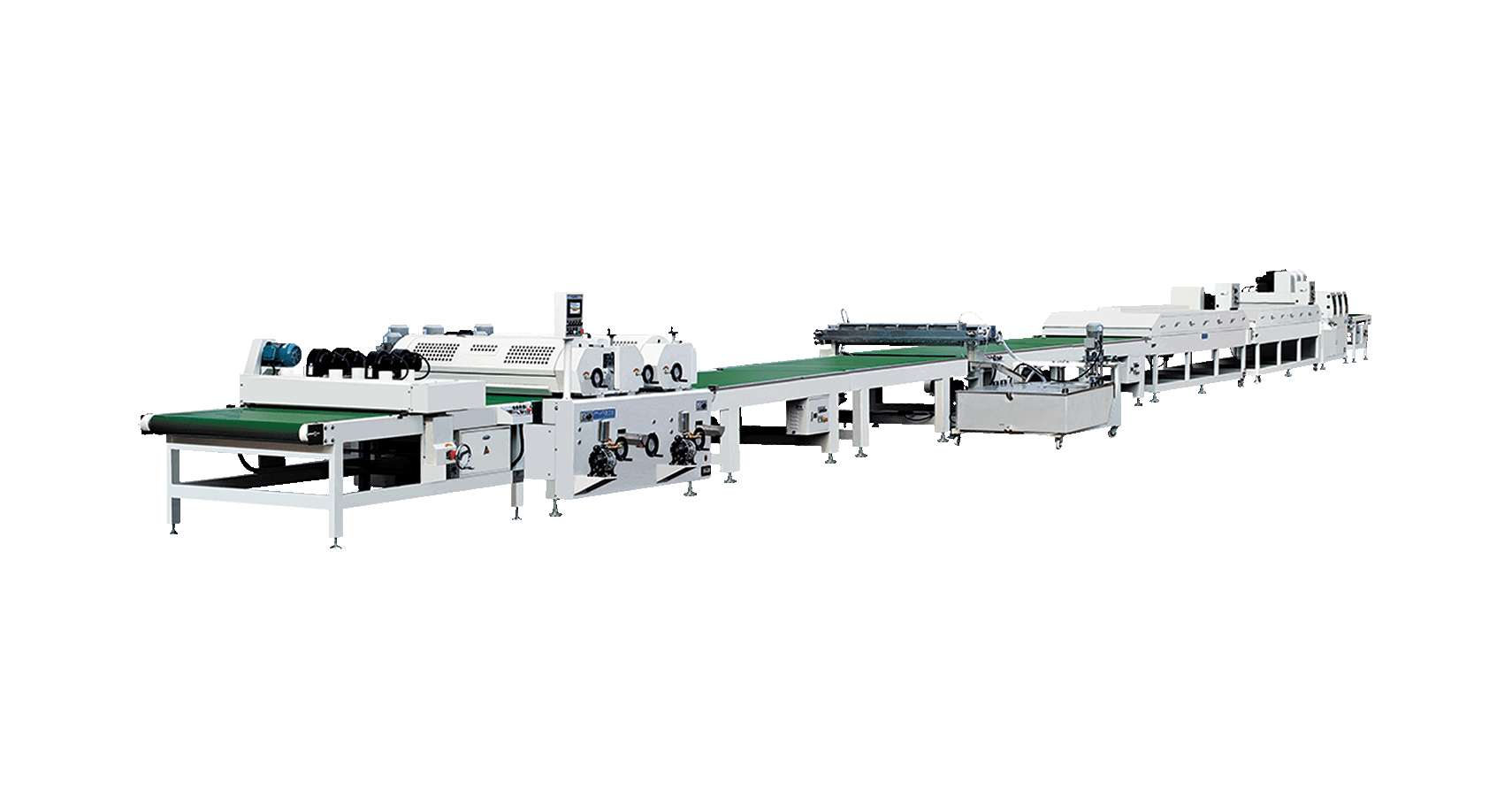

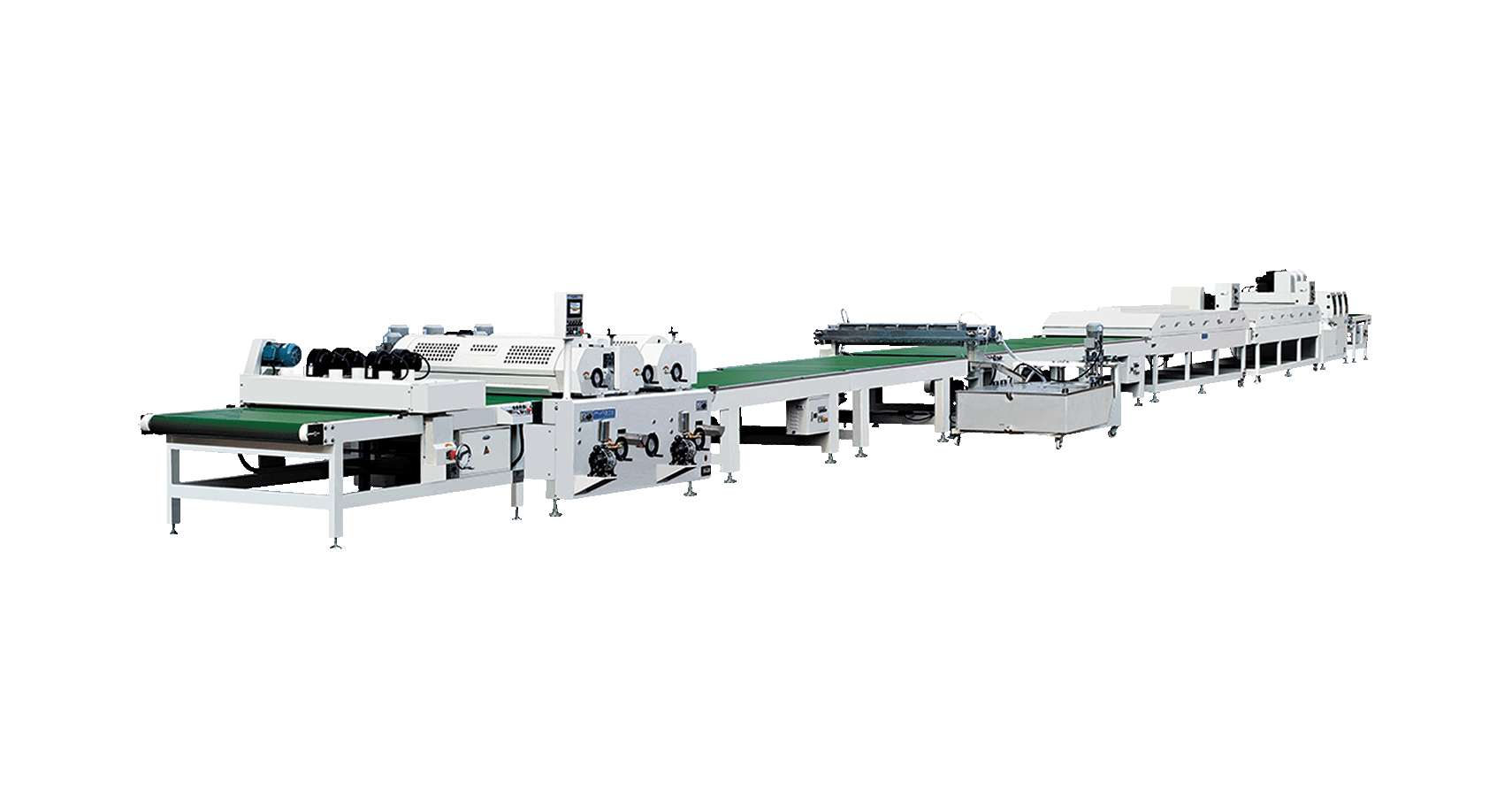

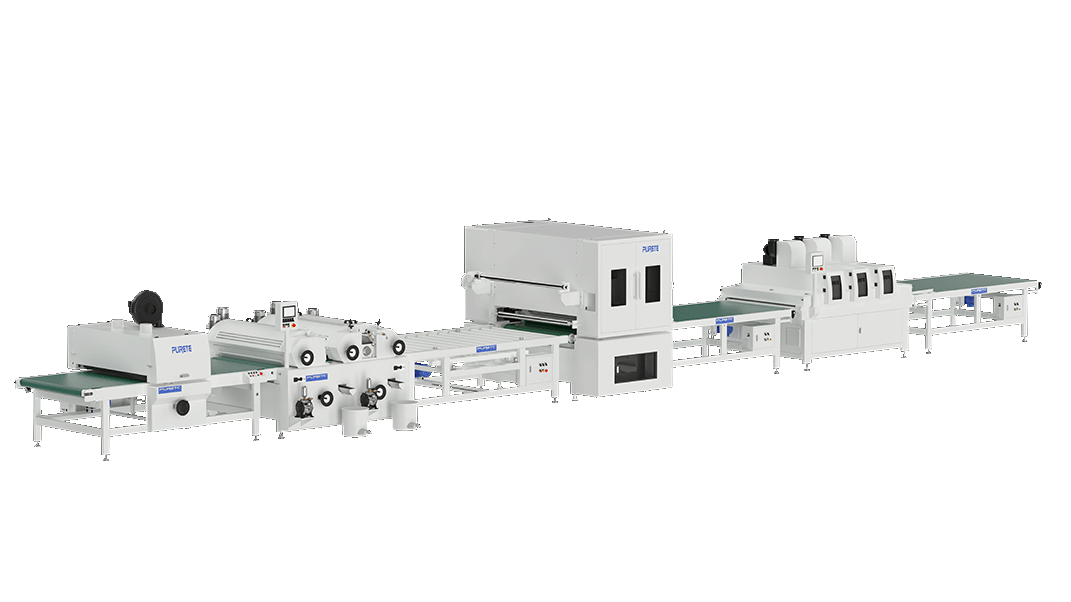

Hits:58secondIn modern manufacturing, surface finishing plays a crucial role in determining the aesthetic appeal, durability, and functional performance of products. Among various coating technologies, Soft-Touch (Excimer) Coating has gained increasing popularity due to its ability to provide a high-end, velvety texture while enhancing surface protection. With the advancement of innovative materials, Excimer coating production lines have evolved significantly, enabling superior performance in industries such as automotive, furniture, consumer electronics, and luxury packaging.

Understanding Soft-Touch (Excimer) Coating

Soft-Touch (Excimer) Coating is a UV-curable surface treatment that utilizes excimer laser technology to create ultra-matte, textured finishes with a pleasant soft-touch feel. The key process involves:

1. Application of UV-curable coatings on the substrate.

2. Exposure to low-wavelength Excimer UV light (172 nm), which initiates surface structuring at the nano level.

3. Curing of the coating layer, creating a non-reflective, ultra-matte effect while maintaining surface durability.

This process not only improves the tactile sensation of coated surfaces but also enhances scratch resistance, anti-fingerprint properties, and chemical durability.

Innovative Material Applications in Excimer Coating

Recent advancements in coating formulations, nano-materials, and hybrid polymer technology have expanded the capabilities of Excimer coatings. Below are some of the most promising material innovations driving the evolution of Soft-Touch (Excimer) Coating production.

1. Advanced UV-Curable Polymers

Traditional UV coatings rely on standard acrylate formulations, but the latest hybrid polymer coatings integrate silicone-modified or polyurethane-based materials. These innovations provide:

· Enhanced flexibility, reducing surface cracking and increasing lifespan.

· Higher scratch resistance, making them ideal for high-touch applications like furniture and automotive interiors.

· Improved adhesion to diverse substrates, including plastics, metals, and glass.

2. Nano-Structured Additives for Improved Soft-Touch Feel

Soft-Touch Coatings have benefited from the development of nano-structured additives, which create microscopic surface textures that enhance tactile sensation.

· Silica-based nano-fillers increase matte effects and minimize light reflection.

· Organic softening agents contribute to a silk-like texture, commonly used in luxury packaging and high-end electronics.

· Polymeric microcapsules offer a more durable Soft-Touch feel, even after extended use.

These materials allow manufacturers to customize the level of softness and improve the overall user experience.

3. High-Performance Excimer-Compatible Pigments

Color stability and optical properties are critical for Soft-Touch finishes. Recent innovations in Excimer-compatible pigments have led to:

· Improved dispersion, ensuring uniform matte effects across the entire surface.

· Better UV stability, preventing color fading or yellowing over time.

· Metallic and pearlescent matte finishes, expanding the design possibilities for premium applications.

These pigments are particularly useful in automotive dashboards, luxury goods packaging, and high-end electronics where aesthetics and longevity are essential.

4. Eco-Friendly & VOC-Free Coating Formulations

As industries move toward sustainable manufacturing, the latest Soft-Touch coatings feature low-VOC, water-based, and bio-based formulations. Benefits include:

· Reduced environmental impact, complying with stricter global regulations.

· Lower emissions, creating a safer workplace for production line workers.

· Improved recyclability, supporting circular economy principles.

Manufacturers are increasingly adopting bio-based urethane coatings, which replace petroleum-derived ingredients with renewable plant-based sources while maintaining high-performance Soft-Touch properties.

5. Self-Healing and Anti-Fingerprint Coatings

One of the latest breakthroughs in Excimer coating technology is the incorporation of self-healing polymers and anti-fingerprint technology.

· Self-healing coatings use microencapsulated polymer networks that can repair minor scratches over time.

· Anti-fingerprint coatings utilize hydrophobic and oleophobic additives to repel oils and smudges, maintaining a clean, high-quality surface.

These features are highly desirable in smartphones, touchscreens, and automotive interiors, where cleanliness and longevity are crucial.

Advantages of These Innovative Materials in Excimer Coating Production

The integration of these advanced materials in Soft-Touch (Excimer) Coating production lines offers several significant advantages:

1. Superior Surface Performance – Higher resistance to abrasion, chemicals, and fingerprints ensures long-lasting quality.

2. Customization Flexibility – Manufacturers can fine-tune matte levels, textures, and colors to meet diverse application needs.

3. Increased Production Efficiency – Advanced materials reduce curing time and enhance adhesion, speeding up production.

4. Sustainability & Compliance – VOC-free, bio-based coatings align with global green manufacturing standards.

5. Enhanced Consumer Experience – Products with soft-touch, anti-smudge, and self-healing properties improve user satisfaction.

Applications of Soft-Touch (Excimer) Coating in Various Industries

Due to these innovations, Excimer-coated surfaces are now widely used in:

· Automotive Interiors – Dashboard panels, control buttons, and door trims for a premium tactile experience.

· Luxury Packaging – High-end cosmetic boxes, perfume bottles, and electronic device packaging.

· Consumer Electronics – Smartphones, laptop casings, and gaming consoles with anti-fingerprint coatings.

· High-End Furniture – Scratch-resistant matte coatings for tables, cabinets, and decorative surfaces.

· Medical Equipment – Soft-touch surfaces in medical devices to improve ergonomics and hygiene.

The advancement of innovative materials in Soft-Touch (Excimer) Coating production lines has revolutionized surface finishing, offering superior durability, aesthetics, and functionality. From UV-curable polymers and nano-structured additives to self-healing coatings and VOC-free formulations, these innovations are driving efficiency and sustainability in various industries.

As manufacturers continue to explore new material applications, Soft-Touch (Excimer) Coating technology will expand its market presence, setting new benchmarks in product quality, user experience, and eco-friendly production. In the coming years, we can expect even more breakthroughs, further enhancing the performance and versatility of Soft-Touch coatings across multiple industries.