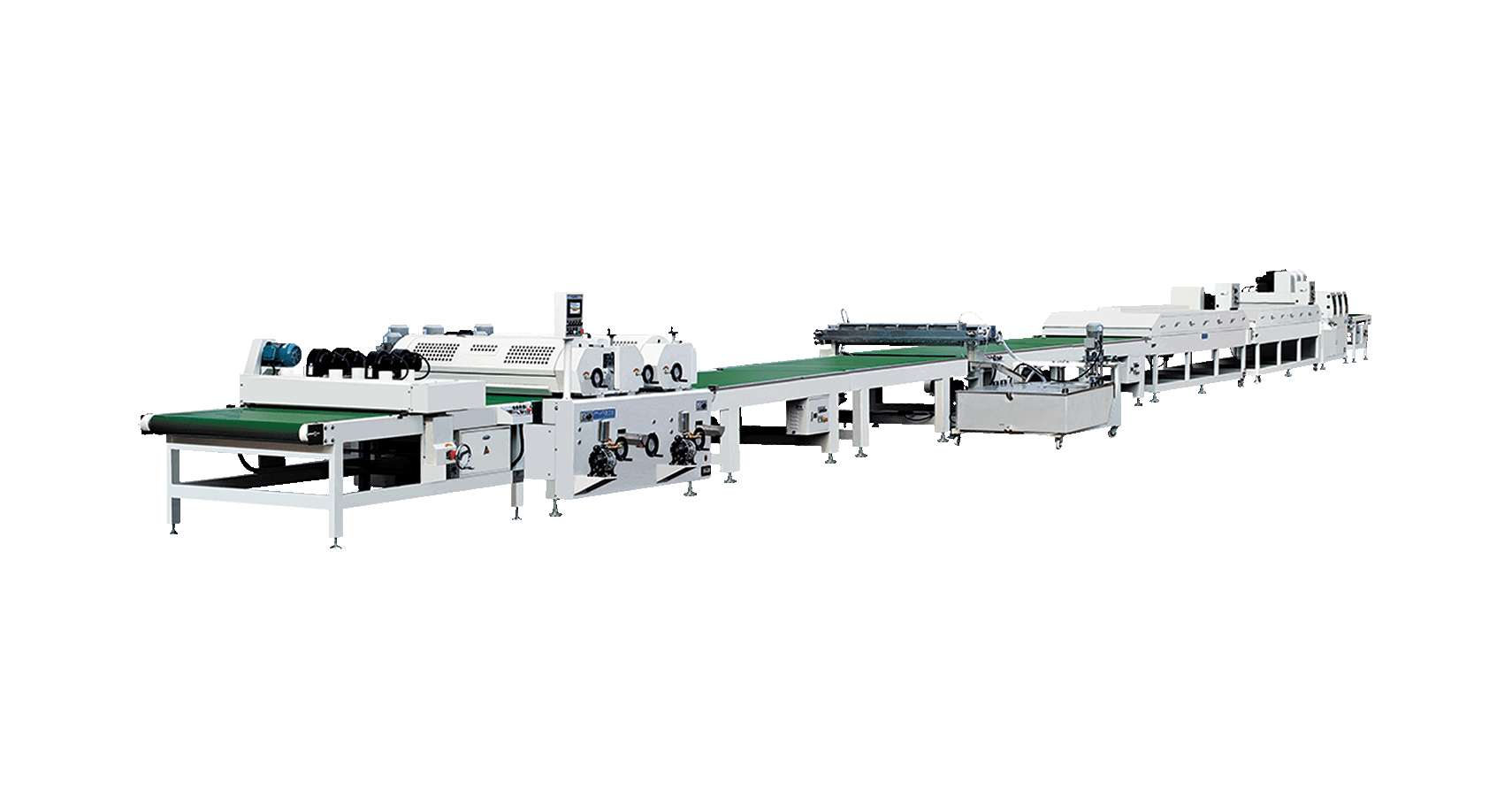

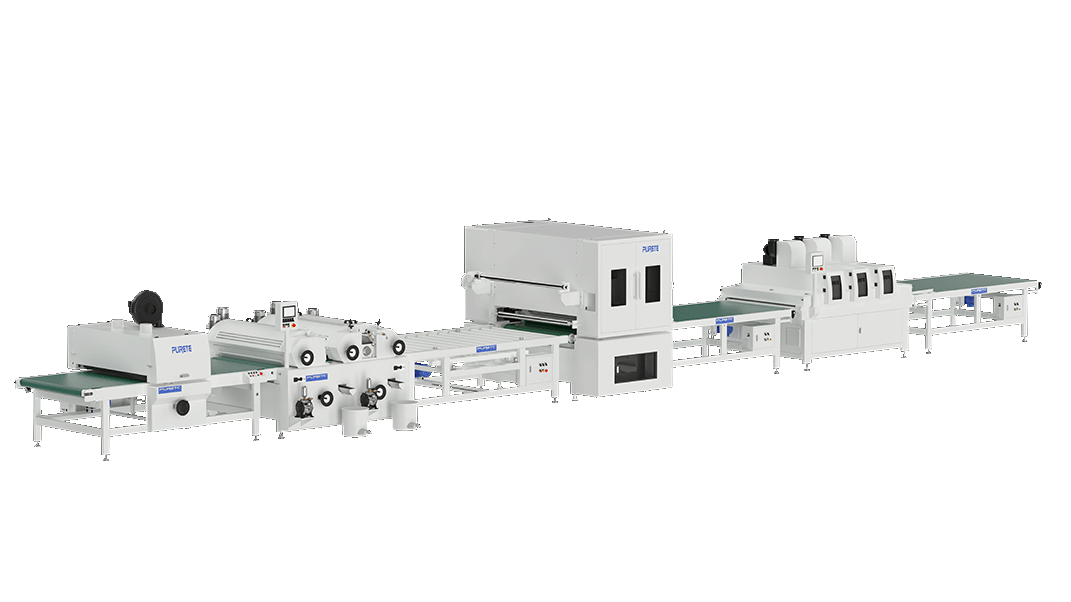

L10A-1950 Curtain Coating Production Line: Pioneering High-Gloss Finishing with Advanced Technology

February 26, 2025

February 26, 2025 Hits:84second

Hits:84secondIn the coating industry, where exceptional quality and a flawless glossy finish are paramount, the L10A-1950 Curtain Coating Production Line stands out with its high-performance capabilities and state-of-the-art technology, designed for large-scale substrates requiring a high-gloss finish.

Product Overview

The L10A-1950 is tailored for wide-type, large-scale substrates, delivering a high-gloss surface suitable for applications like marble and melamine boards. Commonly utilized in interior decorative wall panels, it meets the demands of high-end markets with its superior finishing effects.

Core Components and Functions

Dust Cleaner: Removes dust from the substrate surface prior to coating for uniform application and adhesion.

Forward and Reverse Coater: Offers versatile coating options to accommodate various process requirements.

Curtain Coater: Utilizes advanced curtain coating technology for a smooth, even coating film.

12M IR-Heating Oven: Rapid drying enhances production efficiency and ensures coating quality.

Three-lamp UV Curing: UV light curing for quick hardening and stabilization of the coating.

Technical Advantages

Coating Film: The production line achieves a high-quality, uniform coating film with excellent gloss and durability.

Curtain Coater System: The innovative system ensures continuous and consistent coating, compatible with water-based and high-flow rate materials.

Coating Layer: Adjustable coating layer thickness to meet different gloss and protective requirements.

High Quality: Every stage of the production line is strictly controlled to ensure the highest quality standards.

Flow Rate Control: Precise control of the flow rate to adapt to various coating needs.

Application Areas

The L10A-1950 is suitable for a variety of substrates, including but not limited to:

Marble slabs

Melamine boards

Interior decorative wall panels

Competitive Edge

Compared to competitors, the L10A-1950 Curtain Coating Production Line demonstrates its strengths in:

High Gloss Effect: Delivers an exceptional high-gloss finish.

High Capacity: An optimized production process increases overall capacity.

Eco-friendly Technology: Utilizes water-based coatings to minimize environmental impact.

Thick Coating Capability: Capable of applying thick coatings for enhanced protective performance.

The L10A-1950 Curtain Coating Production Line sets a new benchmark in the coating industry with its efficiency, flexibility, and eco-friendly features. It not only enhances the appearance and performance of products but also provides manufacturers with a strong competitive advantage in the market.