Spraying Painting Machine Production Line: The Art of Precision and Uniformity

February 19, 2025

February 19, 2025 Hits:149second

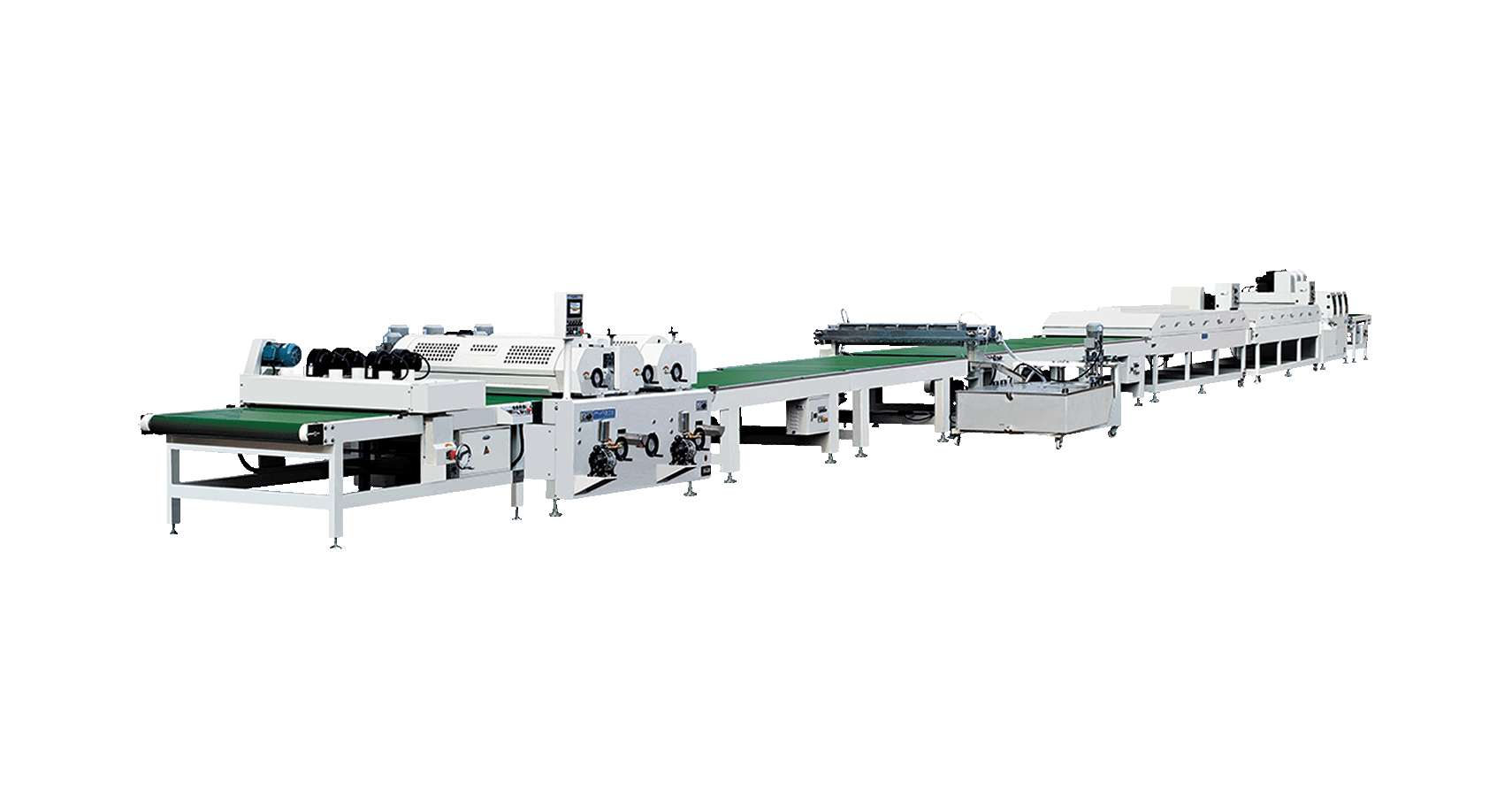

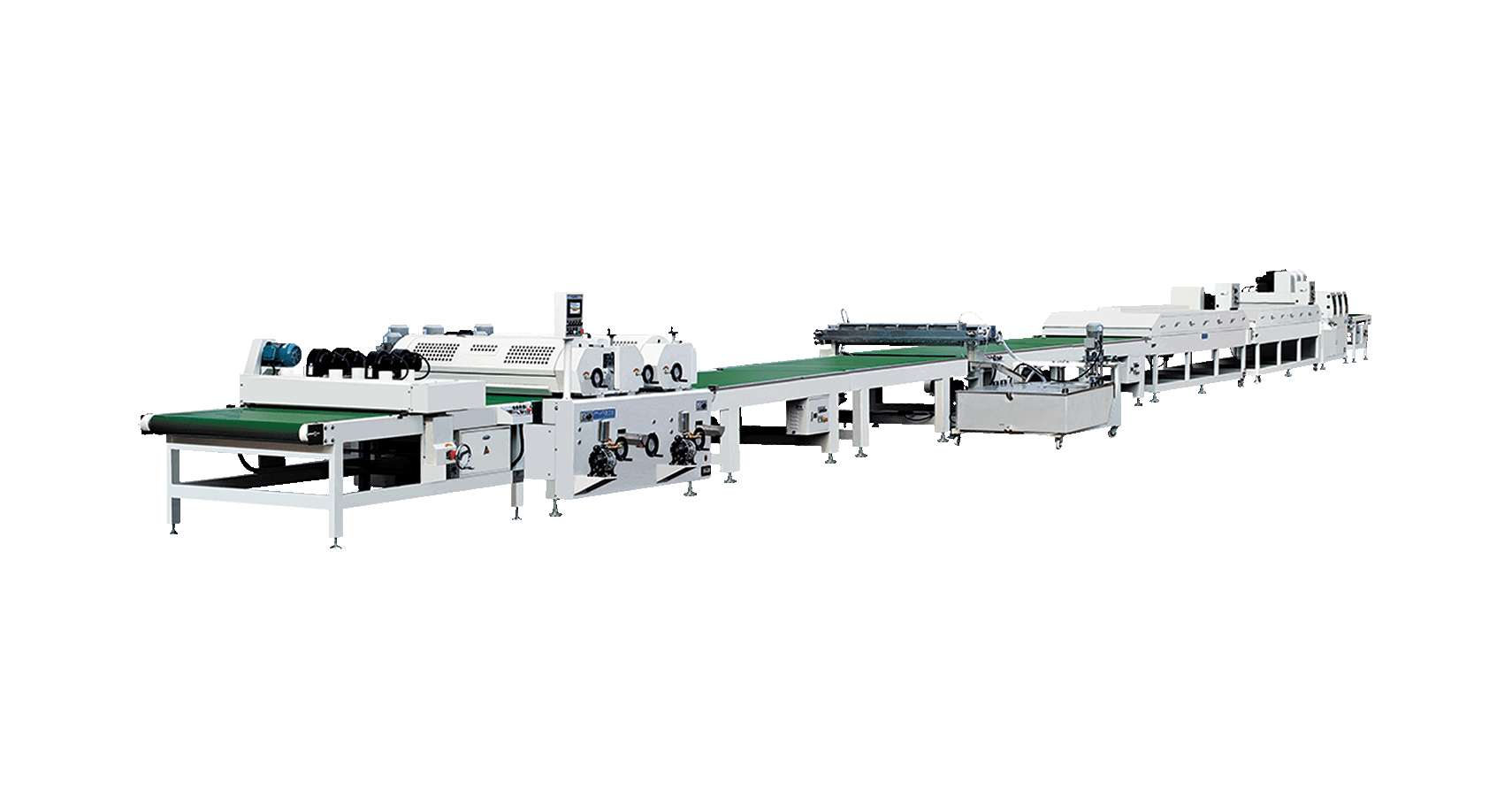

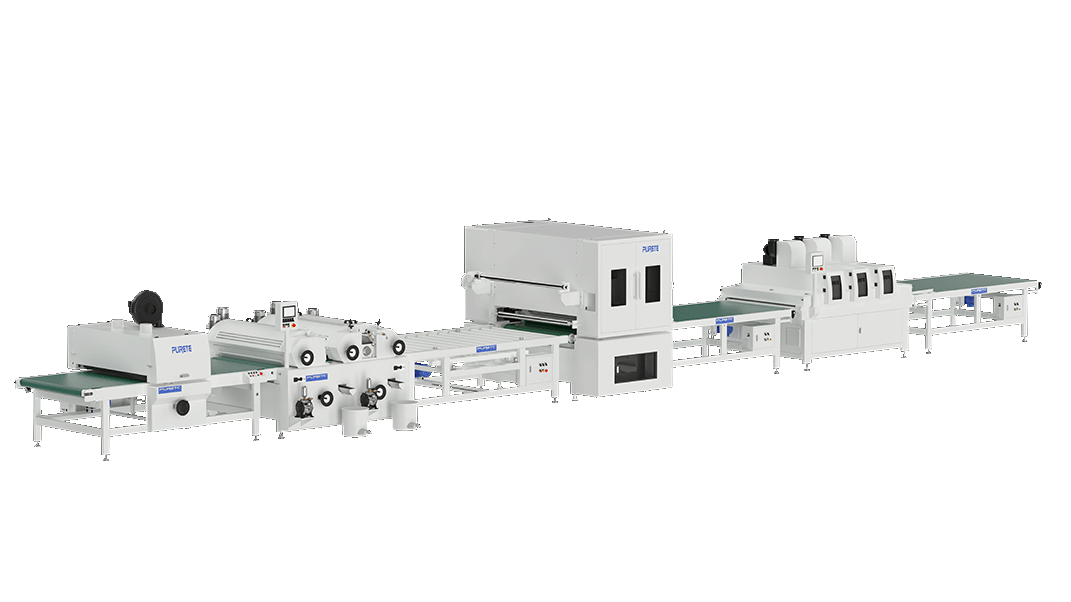

Hits:149secondIn modern manufacturing, achieving a flawless and consistent paint coating is a crucial process that enhances both the appearance and durability of products. The spraying painting machine production line is a sophisticated system designed to deliver precise and uniform coatings across various surfaces. By leveraging advanced technologies, adjustable parameters, and automation, these systems ensure optimal results for a wide range of industrial applications.

Technical Details of Spraying Painting Machine Production Line

A spraying painting machine production line consists of several interconnected components that work together to achieve a high-quality finish. The main elements include:

Pre-Treatment System: This stage involves cleaning, degreasing, and applying a primer to the surface to ensure strong paint adhesion.

Spray Booth: The enclosed environment where paint is applied to minimize contamination and ensure controlled application conditions.

Automatic or Manual Spray Guns: These tools atomize the paint into fine particles for a smooth and even coating.

Conveyor System: A continuous or stepwise mechanism that transports products through the painting process at a controlled speed.

Drying and Curing Chamber: This section ensures proper paint setting through heat treatment, UV curing, or air drying.

Exhaust and Filtration System: Helps maintain air quality by removing excess paint particles and volatile organic compounds (VOCs).

The integration of robotic arms, AI-driven sensors, and electrostatic painting technology further enhances the efficiency and consistency of the spraying painting process.

Optimizing Coating Quality Through Parameter Adjustments

To achieve the best painting results, various parameters must be meticulously adjusted and controlled. The most important parameters include:

1. Spray Pressure and Atomization

Higher pressure results in finer atomization, which provides a smooth and even coat.

Lower pressure can be used for thicker coatings, but it requires proper viscosity control.

2. Paint Viscosity and Flow Rate

Adjusting viscosity ensures the paint flows smoothly through the nozzles and adheres uniformly to the surface.

Flow rate control prevents excessive paint application, reducing drips and overspray.

3. Spray Angle and Distance

Optimal spray angles (typically 45°-90°) ensure maximum coverage without paint wastage.

Maintaining the right distance (usually 15-30 cm) prevents uneven layering and sags.

4. Conveyor Speed and Drying Time

Balancing conveyor speed with paint drying time ensures each product receives the necessary coating without defects.

Controlling drying temperatures prevents paint cracking or poor adhesion.

5. Environmental Conditions

Temperature and humidity control within the spray booth ensures consistent paint application and drying.

Air filtration prevents dust and contaminants from affecting the paint quality.

Application in Complex-Shaped Products

One of the significant advantages of spraying painting machine production lines is their ability to coat complex and irregularly shaped products with precision. Industries such as automotive, aerospace, electronics, and furniture manufacturing benefit greatly from this capability.

1. Multi-Axis Robotic Spraying

Robotic arms with multi-degree movement can efficiently coat intricate and multi-dimensional surfaces.

3D scanning technology enables the system to adapt spraying paths dynamically.

2. Electrostatic Spraying Technology

Charged paint particles are attracted to the product surface, ensuring uniform coverage even in hard-to-reach areas.

This technique is especially useful for grilled surfaces, metal tubing, and components with recessed sections.

3. Customizable Nozzle Designs

Specialized nozzles allow for precise control over spray patterns, making them ideal for complex geometries and delicate details.

Adjustable fan width and spray direction enhance efficiency and minimize overspray.

4. Masking and Shielding Techniques

Automated masking systems protect areas that should not be painted, ensuring clean edges and selective coating.

Laser-guided alignment helps maintain consistency across multiple pieces.

The spray painting machine production line is a technological advancement that combines precision, efficiency, and adaptability. By fine-tuning parameters such as spray pressure, paint viscosity, and conveyor speed, manufacturers can achieve optimal coating results tailored to various industrial needs. The ability to handle complex-shaped products with robotic precision, electrostatic technology, and specialized nozzles further underscores the versatility of these systems.

With continuous advancements in AI integration, environmental sustainability, and automation, spraying painting machines are set to become even more efficient, reducing material waste and improving production quality. Whether in automotive, aerospace, or consumer electronics, investing in an optimized spraying painting production line ensures superior surface finishing, durability, and cost-effectiveness for manufacturers worldwide.