What industries benefit most from PUR laminating machines?

March 10, 2025

March 10, 2025 Hits:18second

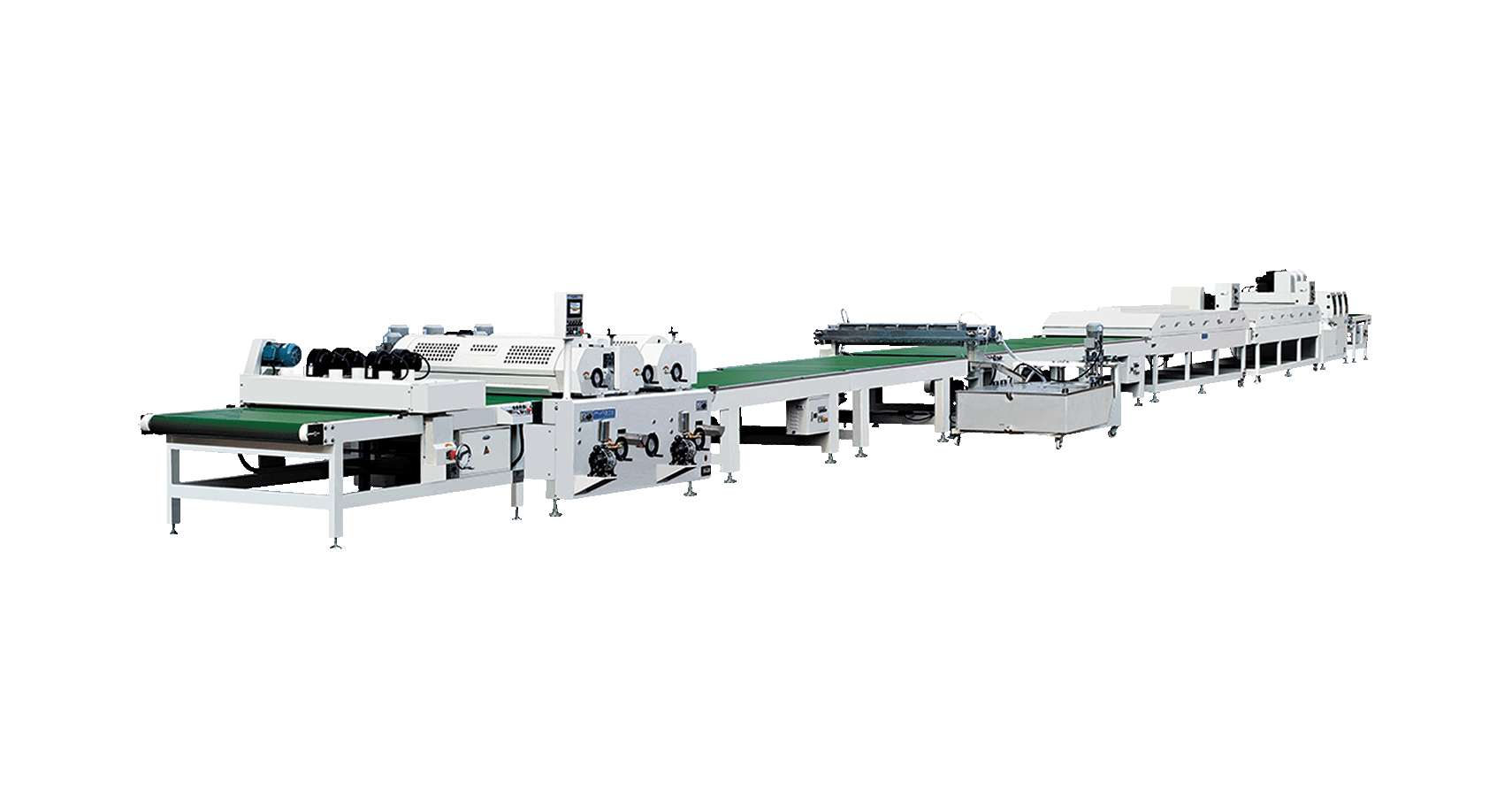

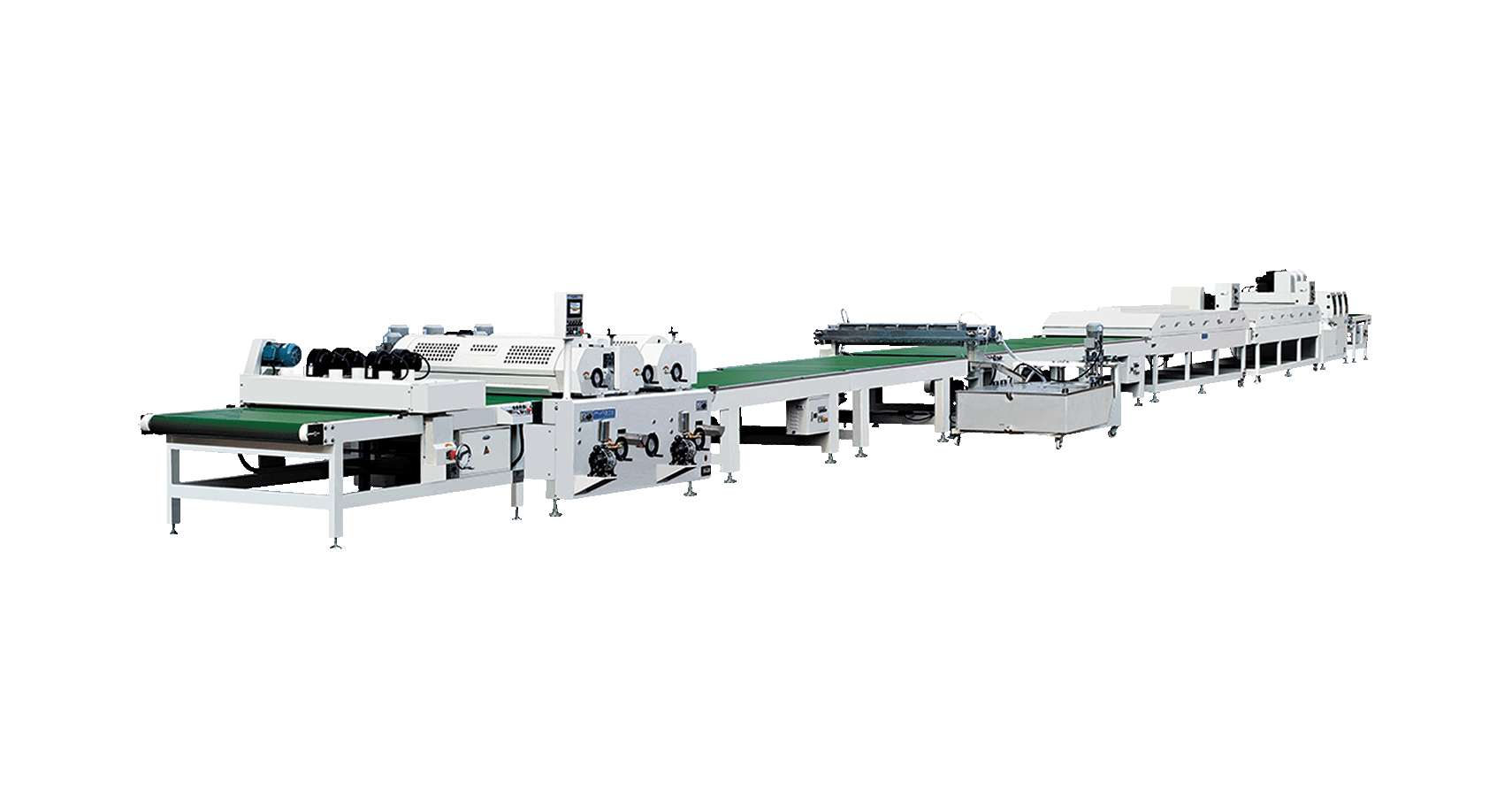

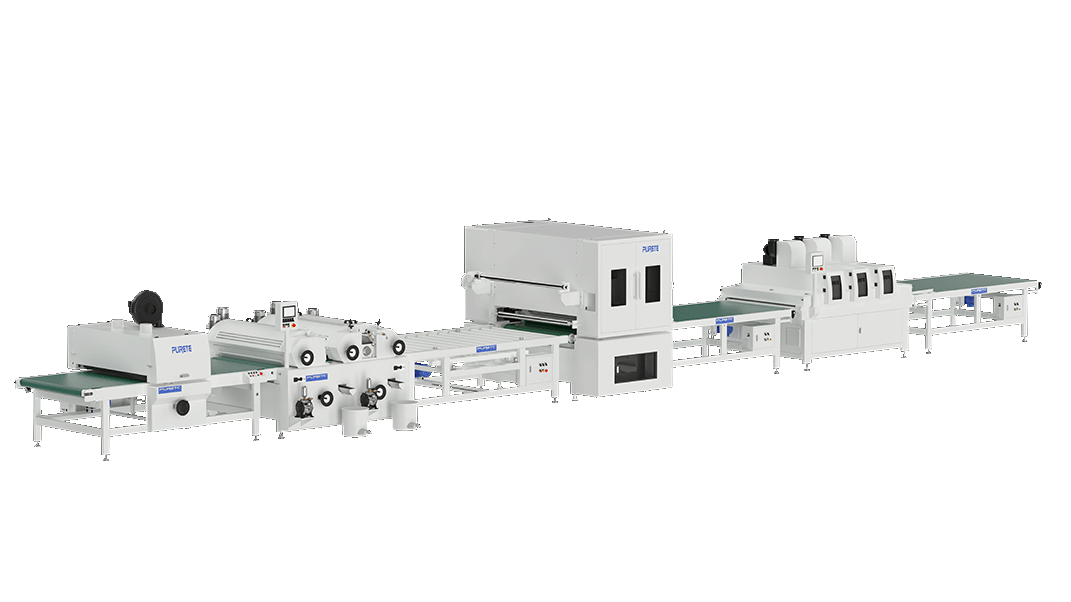

Hits:18secondPolyurethane Reactive (PUR) laminating machines have revolutionized various industries by providing high-performance adhesion, durability, and versatility. Unlike traditional adhesives, PUR adhesives offer superior bonding strength, heat resistance, and flexibility, making them ideal for numerous applications.

1. Furniture and Woodworking Industry

One of the primary industries that extensively use PUR laminating machines is the furniture and woodworking industry. These machines are used to laminate veneers, decorative films, and high-gloss finishes onto wooden panels, MDF, and particleboards. The advantages of using PUR laminating in this industry include:

Enhanced Durability: PUR adhesives create strong, moisture-resistant bonds that prevent delamination.

Aesthetic Appeal: High-gloss and textured finishes improve the visual appeal of furniture pieces.

Eco-Friendly Solutions: Many PUR adhesives are low in volatile organic compounds (VOCs), making them a sustainable choice.

2. Automotive Industry

The automotive sector relies on PUR laminating machines for interior and exterior applications. Some common uses include laminating dashboard components, door panels, and headliners. Key benefits for this industry include:

Heat and Chemical Resistance: PUR adhesives withstand extreme temperatures and exposure to chemicals.

Improved Sound Insulation: Laminated components contribute to noise reduction inside vehicles.

Lightweight Solutions: The use of PUR lamination enables lightweight construction without compromising strength.

3. Packaging Industry

The packaging industry benefits greatly from PUR laminating machines, particularly in flexible and rigid packaging applications. These machines help bond films, foils, and specialty coatings used in food, pharmaceutical, and luxury packaging. Advantages include:

Superior Barrier Properties: Ensures extended shelf life by providing excellent moisture and gas resistance.

High-Speed Production: PUR laminating allows for efficient, large-scale packaging operations.

Sustainable Packaging: Compatible with recyclable and biodegradable materials.

4. Textile and Leather Industry

PUR laminating technology plays a crucial role in the textile and leather industries by bonding multiple layers of fabrics, synthetic leather, and breathable membranes. Applications include:

Outdoor and Sportswear: Enhances waterproofing and durability in garments.

Automotive and Upholstery Leather: Provides long-lasting adhesion to synthetic and natural leather.

Medical and Protective Textiles: Ensures hygiene and protection in medical-grade fabrics and protective gear.

5. Electronics Industry

The electronics industry uses PUR laminating machines for assembling display screens, touch panels, and protective films. The benefits in this sector include:

Precision Bonding: Ensures smooth application without bubbles or defects.

Heat and Humidity Resistance: Provides long-lasting performance in electronic devices.

Flexible and Durable Adhesion: Supports bendable and foldable screen technologies.

6. Construction and Interior Design

In construction and interior design, PUR laminating machines are used for wall panels, flooring, and decorative laminates. The key advantages include:

Strong Adhesion to Various Substrates: Works on wood, glass, metal, and composite materials.

Weather and Moisture Resistance: Ideal for both indoor and outdoor applications.

Aesthetic Versatility: Enables the creation of high-quality, realistic wood, marble, and textured finishes.

7. Graphic Arts and Printing Industry

PUR laminating machines are widely used in the graphic arts and printing industry to produce high-quality book covers, banners, and commercial prints. The advantages include:

Superior Print Protection: Enhances durability and prevents fading.

Glossy and Matte Finishes: Provides aesthetic appeal for high-end print materials.

Resistance to Scratches and Water Damage: Ensures long-term preservation of printed materials.

PUR laminating machines are indispensable across multiple industries, from furniture and automotive to packaging and textiles. Their ability to provide strong, flexible, and durable adhesion makes them an essential tool for enhancing product quality and performance. As technology advances, the demand for PUR lamination is expected to grow, further driving innovation and efficiency in these industries.