The Comprehensive Guide to Curtain Coating Machines

February 28, 2025

February 28, 2025 Hits:78second

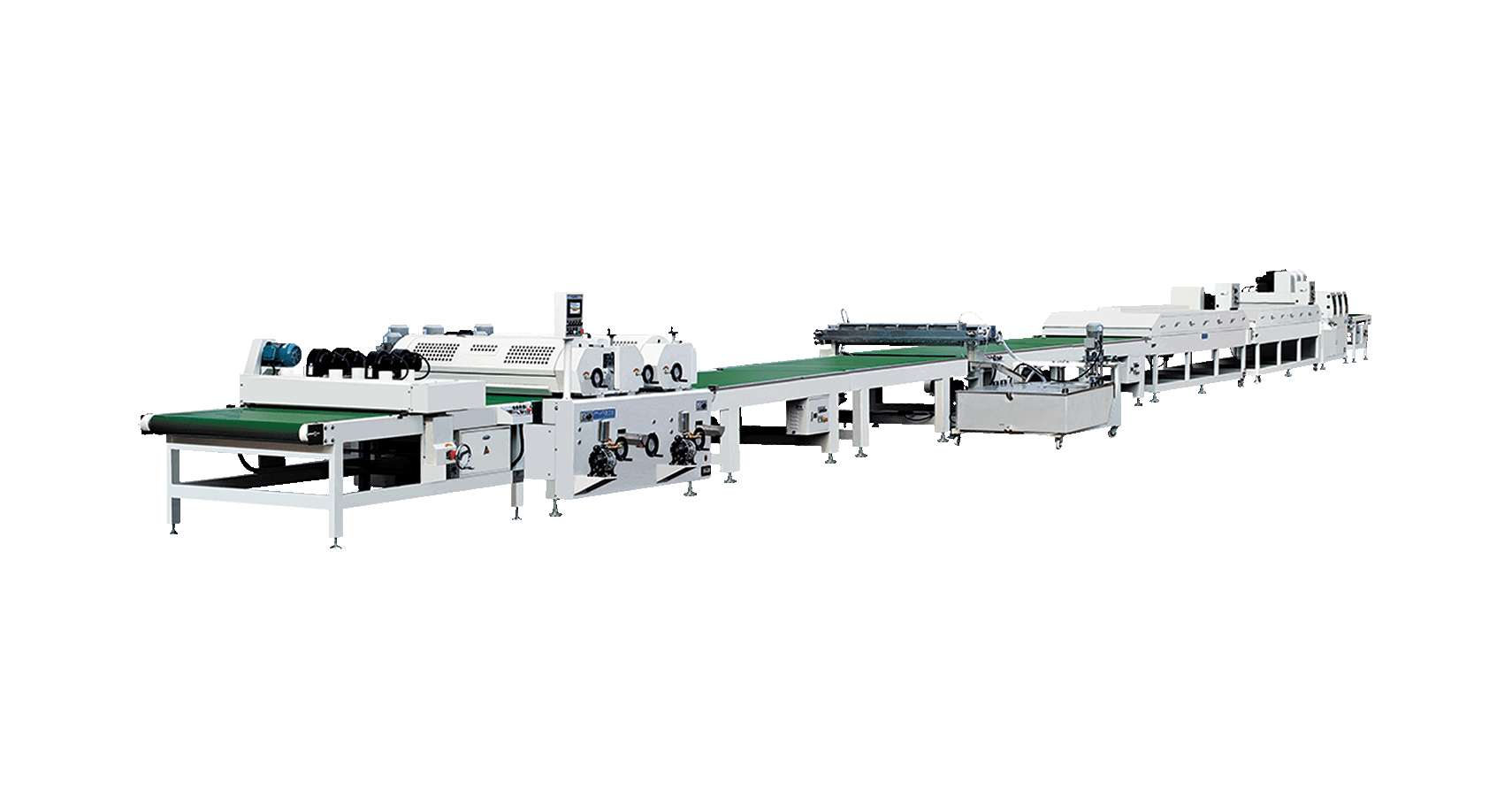

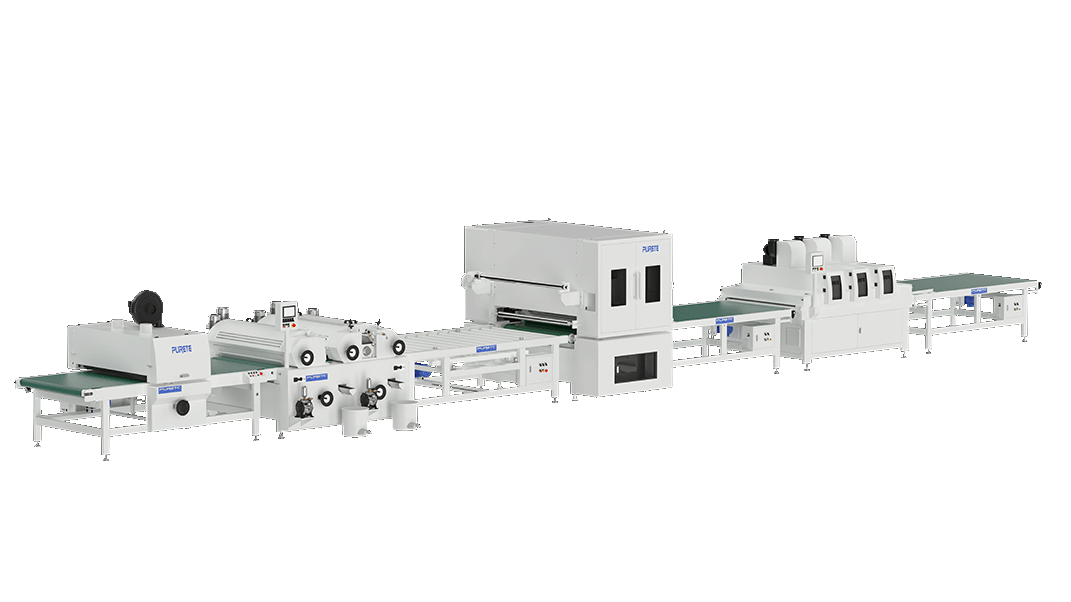

Hits:78secondA curtain coating machine is a specialized piece of equipment used in the manufacturing process to apply a uniform layer of liquid material onto a substrate. This technology is widely used in various industries, including paper, film, and textile manufacturing, to achieve precise and consistent coating applications.

Working Principle

The curtain coating machine operates on the principle of creating a continuous curtain of liquid material that falls onto a moving substrate. The substrate, typically a web of paper, film, or fabric, passes under the curtain at a controlled speed, ensuring that the liquid is evenly distributed across its surface. The key to achieving a uniform coating lies in the precise control of the liquid flow, the speed of the substrate, and the distance between the curtain and the substrate.

Components of a Curtain Coating Machine

Reservoir: The reservoir holds the liquid material to be coated. It is designed to maintain a consistent level of liquid, ensuring a steady supply to the curtain.

Curtain Forming Device: This component creates the curtain of liquid. It typically consists of a slot or nozzle through which the liquid is extruded to form a continuous sheet.

Substrate Handling System: The substrate handling system includes rollers and guides that control the movement of the substrate under the curtain. The speed and tension of the substrate are carefully managed to ensure uniform coating.

Drying System: After the liquid is applied, the coated substrate passes through a drying system to remove excess moisture and solidify the coating. This can involve hot air drying, infrared drying, or other methods depending on the material and application.

Control System: The control system manages the entire coating process, including the flow rate of the liquid, the speed of the substrate, and the drying conditions. Modern curtain coating machines often use advanced automation and sensors to ensure precise control and consistent results.

Benefits of Curtain Coating Machines

Uniform Coating: The curtain coating process ensures a highly uniform coating, which is crucial for applications where consistency is essential, such as in the production of high-quality paper and films.

Efficiency: Curtain coating machines can operate at high speeds, making them suitable for large-scale production. The continuous process reduces downtime and increases overall efficiency.

Versatility: These machines can handle a wide range of materials, including water-based and solvent-based coatings, making them suitable for various industrial applications.

Cost-Effectiveness: The ability to apply precise amounts of coating material reduces waste and lowers production costs. Additionally, the uniform coating reduces the need for post-processing steps, further saving time and resources.

Environmental Friendliness: Modern curtain coating machines are designed to minimize solvent emissions and reduce environmental impact, making them a more sustainable choice for manufacturing processes.

Applications of Curtain Coating Machines

Paper and Board: Curtain coating is widely used in the paper industry to apply coatings such as varnishes, inks, and functional coatings to improve the appearance and performance of paper products.

Film Manufacturing: In the production of plastic films, curtain coating is used to apply layers of adhesive, barrier coatings, and other functional materials to enhance the properties of the film.

Textile Industry: Curtain coating machines are used to apply coatings to fabrics for applications such as waterproofing, flame retardancy, and UV protection.

Electronics: In the electronics industry, curtain coating is used to apply conductive and insulating coatings to substrates for the production of printed circuit boards and other electronic components.

Pharmaceuticals: Curtain coating machines are also used in the pharmaceutical industry to coat tablets and other dosage forms with protective or functional coatings.

A curtain coating machine is a versatile and efficient tool for applying uniform coatings to a wide range of substrates. Its precise control and high-speed operation make it an essential piece of equipment in various manufacturing industries. Whether used in paper production, film manufacturing, or electronics, curtain coating machines offer significant benefits in terms of uniformity, efficiency, and cost-effectiveness. As technology continues to advance, curtain coating machines are likely to become even more sophisticated, further enhancing their capabilities and applications in the manufacturing sector.