Why Are Coatings So Important?

August 06, 2024

August 06, 2024 Hits:515second

Hits:515secondCoatings are crucial in various industries, providing protection, functionality, and aesthetics to products. From automotive parts to electronic devices, coatings enhance durability, performance, and appearance. Advanced technologies like Purete's roller coating production line have revolutionized the application of coatings, ensuring precision and efficiency.

Why Are Coatings Used?

Protection

Coatings protect substrates from environmental factors such as corrosion, UV radiation, moisture, and chemical exposure. For instance, in the automotive industry, coatings prevent rust and extend the lifespan of car parts.

Functionality

Coatings can impart specific properties to a substrate, such as waterproofing, heat resistance, electrical conductivity, or anti-microbial characteristics. In electronics, coatings insulate and protect components from damage, ensuring device reliability.

Aesthetics

Coatings enhance the visual appeal of products by providing a smooth, glossy, or matte finish. They can also add color and texture, making products more attractive to consumers. Packaging materials often use coatings to improve both appearance and durability.

Purete's Roller Coating Production Line

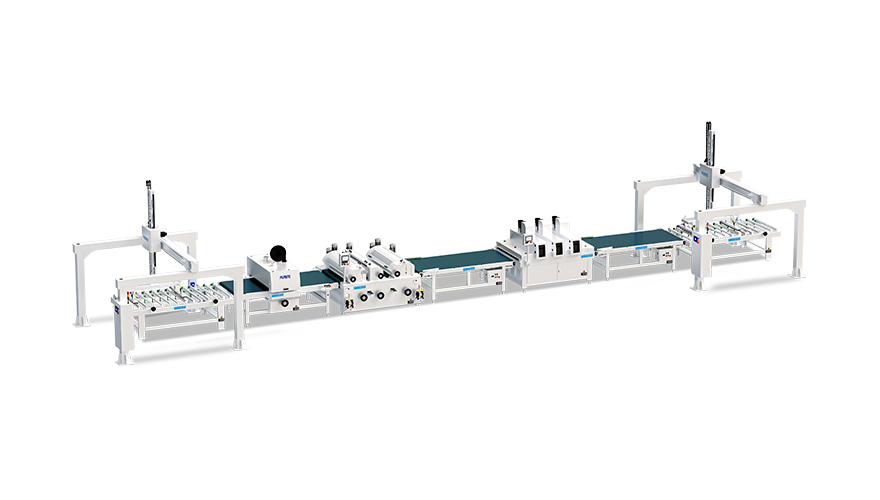

Purete Mac's advanced roller coating production lines are designed to apply coatings uniformly and efficiently. Key features include:

Precision: Ensures consistent coating thickness, crucial for product quality and performance.

Versatility: Capable of handling various coating materials, including paints, adhesives, and resins, suitable for different substrates.

Efficiency: High-speed operations and automated control systems enhance productivity and reduce operational costs.

Applications of Coatings

Construction and Renovation:

Interior and exterior paints: provide an aesthetic appearance while protecting walls from moisture, mold and stains.

Wood paint: Protects wood from moisture and UV damage while providing a variety of colors and gloss effects.

Furniture and home furnishings:

Decorative Coatings: used on furniture and upholstery to provide an aesthetically pleasing finish.

Protective coatings: protect furniture from scratches and everyday wear and tear.

Automotive Industry:

Primer: provides corrosion protection for automobiles.

Intermediate and top coats: provide a durable coating that enhances the aesthetics and weather resistance of the car.

Clear coats: provide an additional layer of protection, adding gloss and scratch resistance.

Electronics:

Conductive Coatings: used on circuit boards and other electronic components to provide conductive properties.

Anti-corrosion coatings: protect electronic equipment from corrosion and oxidation.

Packaging Industry:

Barrier coatings: used in food packaging materials to prevent oxygen and moisture penetration and extend product shelf life.

Printing inks: used for pattern and text printing on packaging.

Marine and Offshore:

Anti-fouling coatings: prevent marine organisms from attaching to the hull, reduce drag and improve fuel efficiency.

Protective coatings: protect hulls and marine structures from salt and seawater corrosion.

Medical Equipment:

Antimicrobial Coatings: used on hospital equipment and surfaces to reduce the spread of bacteria and viruses.

Protective Coatings: to protect medical equipment from chemical and physical damage.

Sports Facilities:

Athletic Field Coatings: used on basketball courts, soccer fields, etc. to provide a non-slip, abrasion-resistant surface.

Industry Trends and Innovations

Sustainability

The development of eco-friendly coatings aims to reduce environmental impact. Water-based and low-VOC (volatile organic compounds) coatings are becoming more popular as sustainable alternatives.

Advanced Materials

Nanotechnology and innovative polymers are being used to create coatings with enhanced properties, such as increased durability, better adhesion, and improved resistance to wear and tear.

Automation

Automation in coating application processes, such as Purete's G1-1 Automatic Roller coating production line, Intelligent unmanned production, ensures precise control, reduces labor costs, and increases production efficiency.

Coatings play a vital role in modern manufacturing, offering protection, functionality, and aesthetic improvements to a wide range of products. Technologies like Purete's roller coating production lines have advanced the application of coatings, ensuring high-quality, efficient, and versatile solutions for various industries.