What are the advantages of roller coating?

March 18, 2025

March 18, 2025 Hits:146second

Hits:146secondRoller coating is a widely used finishing process in various industries, including furniture, automotive, construction, and packaging. It involves the application of a coating material, such as paint, varnish, adhesive, or lacquer, onto a substrate using rollers. This method provides several advantages over other coating techniques, making it a preferred choice for manufacturers seeking efficiency, cost-effectiveness, and high-quality finishes.

1. High Efficiency and Productivity

One of the primary advantages of roller coating is its ability to achieve high production rates. Compared to traditional spraying or dipping methods, roller coating can:

Apply coatings quickly and uniformly over large surfaces.

Reduce production time by minimizing drying and curing times.

Allow for continuous processing, improving workflow efficiency in automated manufacturing lines.

This makes roller coating particularly suitable for industries with high-volume production needs, such as furniture manufacturing and metal fabrication.

2. Consistent and Uniform Coating Application

Roller coating provides a uniform layer of coating material, ensuring consistent quality across all coated surfaces. This consistency is crucial in industries that require precise finishes, such as:

Furniture and Woodworking: Ensures even application of stains, sealers, and lacquers on wooden surfaces.

Metal Coating: Provides a smooth, even finish for metal sheets, preventing defects such as uneven coverage or excess material buildup.

Unlike spray coating, which may result in overspray and uneven thickness, roller coating ensures that the applied material is spread evenly, leading to superior surface quality.

3. Reduced Material Waste and Cost Efficiency

Roller coating minimizes material waste, making it a cost-effective coating solution. Key factors contributing to material savings include:

Precise Application: The controlled deposition of coatings reduces excess usage.

Minimal Overspray: Unlike spray coating, roller coating eliminates airborne waste and overspray issues.

Efficient Use of Coating Materials: The ability to reclaim and reuse excess coating further enhances cost-effectiveness.

Manufacturers benefit from lower material costs and reduced environmental impact due to less waste generation.

4. Environmentally Friendly Process

With increasing emphasis on sustainability, roller coating stands out as an eco-friendly option. Its environmental advantages include:

Reduced Volatile Organic Compounds (VOCs): Less solvent-based waste is generated compared to spray coating.

Lower Energy Consumption: Roller coating requires less energy for application and drying than other methods.

Minimized Air Pollution: Since there is no overspray, the process does not release harmful particulates into the air.

These factors make roller coating an ideal choice for industries looking to comply with environmental regulations and adopt sustainable manufacturing practices.

5. Versatility in Application

Roller coating is highly versatile and can be used for various substrates and coating materials, including:

Wood: Paints, stains, and lacquers for furniture, doors, and flooring.

Metal: Protective coatings for automotive parts, appliances, and construction materials.

Plastics: Decorative and functional coatings for consumer goods.

Paper and Packaging: Coatings for printed materials, labels, and flexible packaging.

The adaptability of roller coating makes it suitable for multiple industries, allowing manufacturers to meet diverse product requirements.

6. Enhanced Surface Quality and Performance

Coatings applied through roller coating enhance the durability and aesthetic appeal of surfaces. Benefits include:

Improved Adhesion: Ensures strong bonding between the coating and the substrate.

Scratch and Wear Resistance: Provides a protective layer against mechanical damage.

Chemical and Moisture Resistance: Extends the lifespan of coated products, particularly in outdoor and industrial applications.

These advantages make roller coating ideal for applications where durability and high-quality finishes are essential.

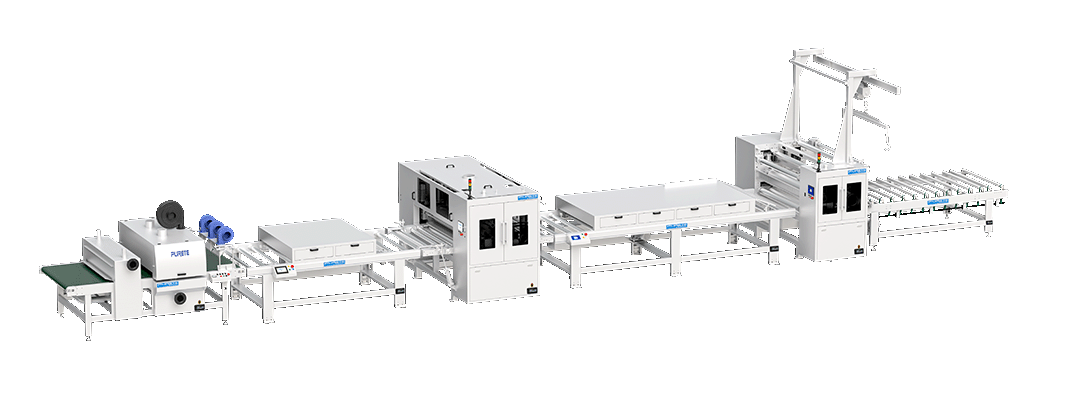

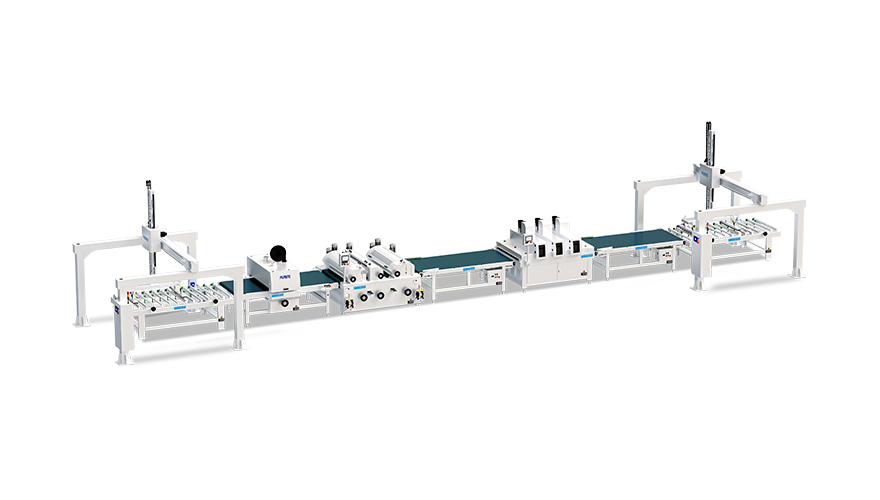

7. Automation and Scalability

Modern roller coating systems can be fully automated, reducing the need for manual labor and increasing production efficiency. Automation benefits include:

Consistent Quality Control: Reduces variability in coating thickness and finish.

Increased Throughput: Supports high-speed manufacturing processes.

Scalability: Easily integrates with existing production lines to accommodate growing demand.

Industries such as automotive and furniture manufacturing benefit from the scalability and precision of automated roller coating systems.

Roller coating offers numerous advantages over other coating methods, making it a preferred choice for manufacturers in various industries. Its high efficiency, uniform application, cost-effectiveness, and environmental benefits contribute to improved production quality and sustainability. Whether applied to wood, metal, plastic, or paper, roller coating provides durable and aesthetically pleasing finishes, enhancing product performance and longevity. As industries continue to seek innovative and sustainable coating solutions, roller coating remains a key technology in modern manufacturing