Guide to Selecting the Right Roller Coating Machine

August 09, 2024

August 09, 2024 Hits:443second

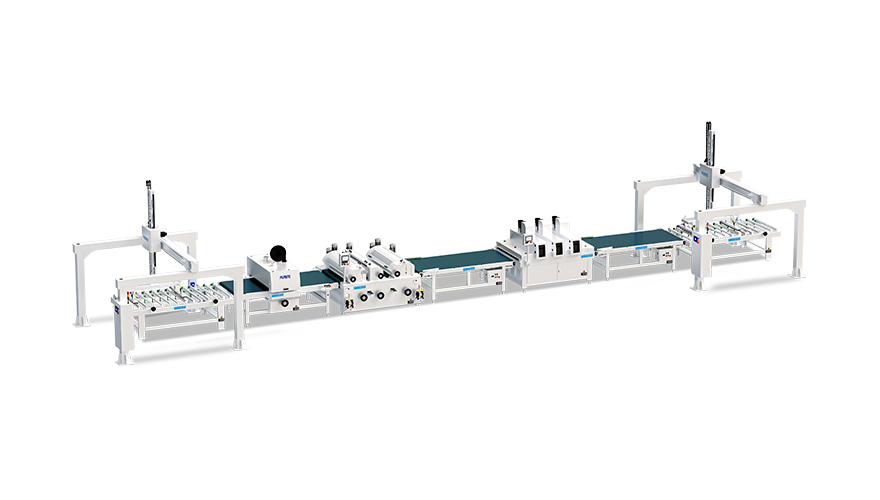

Hits:443secondAs a leading manufacturer of high-performance roller coating machines, I'm excited to share our expertise and guide you through the process of choosing the best solution for your unique business needs. At PURETE, we understand that the right roller coating machine can be a game-changer, driving productivity, quality, and efficiency in your operations.

Importance of Roller Coating Machines

Roller coating is a versatile and widely-used industrial coating technique that offers a range of benefits over traditional coating methods. By applying a uniform and consistent layer of material onto a substrate, roller coating can enhance the appearance, durability, and functionality of a wide variety of products, from furniture and automotive parts to construction materials and electronics.

Investing in a top-quality roller coating machine is crucial for businesses looking to stay competitive and meet the ever-evolving demands of their customers. These advanced machines not only improve the quality of your coatings but also streamline your production processes, reduce material waste, and enhance overall efficiency.

Key Features to Consider When Choosing a Roller Coating Machine

When it comes to selecting the right roller coating machine for your business, there are several key features and specifications to consider. At PURETE, we've identified the following as the most important factors to evaluate:

Precision Coating Control

One of the most critical aspects of a roller coating machine is its ability to precisely control the coating thickness and distribution. Look for machines with advanced features like intelligent thickness monitoring, real-time coating adjustments, and high-accuracy roller positioning systems. These capabilities ensure a consistent and uniform coating finish across your entire production run.

Material Compatibility

Depending on your specific coating requirements, you'll need to ensure that the roller coating machine you choose is compatible with the materials you'll be using. Whether it's water-based, solvent-based, high-viscosity, or UV-curable coatings, the machine should be designed to handle the unique properties of your chosen materials without compromising quality or efficiency.

Versatility and Adaptability

Your business needs may evolve over time, so it's important to select a roller coating machine that can adapt to changing requirements. Look for machines with multi-functional capabilities, such as the ability to handle a variety of substrate materials, accommodate different coating formulations, and integrate seamlessly with other production equipment.

Energy Efficiency and Sustainability

As environmental concerns continue to grow, it's crucial to prioritize energy-efficient and eco-friendly roller coating solutions. PURETE's machines are engineered to minimize energy consumption and reduce the environmental impact of your coating processes, helping you meet your sustainability goals while maintaining high productivity.

Automation and Intelligent Controls

Advanced roller coating machines like those from PURETE feature intelligent control systems and automation capabilities that can significantly enhance your production efficiency. Look for features like automated cleaning, real-time process monitoring, and integrated data analytics to optimize your coating operations and minimize downtime.

Evaluating Roller Coating Machine Performance and Efficiency

When assessing the performance of a roller coating machine, it's important to consider not just the machine's technical specifications but also its real-world impact on your production processes. At PURETE, we pride ourselves on delivering machines that not only meet but exceed the expectations of our customers.

Consistent Coating Quality

One of the key measures of a roller coating machine's performance is the quality and consistency of the coatings it produces. PURETE's machines are engineered to deliver a flawless, defect-free finish, ensuring that your products meet the highest standards of quality and customer satisfaction.

Enhanced Productivity and Throughput

Our roller coating machines are designed to maximize your production efficiency, with features like high-speed coating, automated material handling, and integrated quality control measures. This translates to increased throughput, reduced downtime, and greater overall productivity for your business.

Reduced Material Waste and Operational Costs

By precisely controlling the coating thickness and minimizing material usage, PURETE's roller coating machines help you minimize waste and optimize your material consumption. This, combined with their energy-efficient design and low maintenance requirements, can significantly reduce your operational costs and improve your bottom line.

Partnering with PURETE: Your Trusted Roller Coating Machine Manufacturer

At PURETE, we take pride in being a leading manufacturer of innovative and reliable roller coating machines. With decades of experience in the industry, our team of experts is dedicated to providing you with the best possible solutions for your business.

Commitment to Innovation

Innovation is at the core of everything we do at PURETE. We are constantly researching and developing new technologies to stay ahead of the curve, ensuring that our roller coating machines are equipped with the latest features and capabilities to meet the evolving needs of our customers.

Tailored Solutions for Your Unique Needs

We understand that every business is unique, with its own specific coating requirements and production challenges. That's why PURETE offers a range of customizable roller coating machines, allowing you to select the perfect solution for your application and industry.