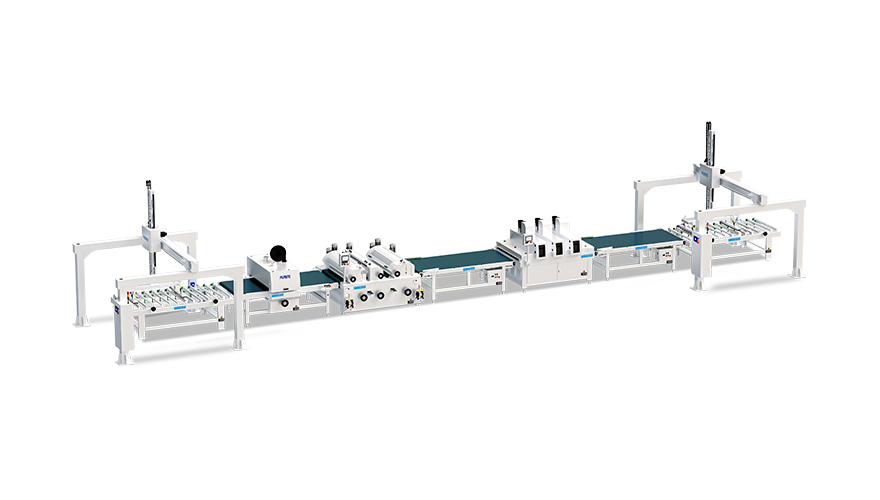

G1-1 Automatic Roller Coating Production Line: Revolutionizing Panel Painting with Intelligent Unmanned Systems

July 19, 2024

July 19, 2024 Hits:551second

Hits:551secondIn the realm of industrial manufacturing, the G1-1 Automatic Roller Coating Production Line stands out as a cutting-edge solution tailored for large panel production. This advanced system boasts fully automated loading and unloading capabilities, eliminating the need for manual labor and significantly reducing manpower costs. The integration of intelligent control systems further enhances its efficiency, making it a prime example of modern manufacturing technology.

Unmatched Efficiency with Four-Legged Gantry System

One of the standout features of the G1-1 production line is its four-legged gantry system. This innovative design facilitates automatic loading and unloading, achieving a maximum speed of six pieces per minute. The gantry system’s automation not only enhances productivity but also ensures precision and consistency in handling large panels, which is critical in maintaining high-quality output. By minimizing human intervention, the system reduces the risk of errors and enhances overall operational efficiency.

Advanced Filling and Roller Coating Machine

The G1-1 production line includes a specialized filling and roller coating machine. This dual-function machine is adept at filling and repairing wood holes on the surface of boards, as well as scraping and plastering putty. The machine’s ability to perform these tasks simultaneously streamlines the production process, reducing the time and effort required to prepare panels for painting. This ensures a smooth and even surface, which is essential for achieving a high-quality finish.

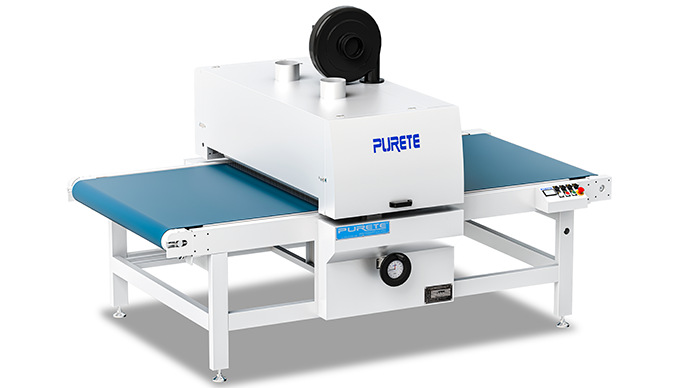

Robust Dust Cleaning Mechanism

Maintaining a clean substrate surface is crucial for optimal coating adhesion. The G1-1 production line addresses this need with a robust dust cleaner. Constructed with an 18mm steel plate welding structure, the dust cleaner is both stable and solid, capable of enduring rigorous operational demands. It features a casting whole seat and a 2.5T load-bearing lifting seat, ensuring stability during operation. The high-quality Siemens motor, combined with an RV reducer or hyperbolic reducer, delivers consistent power output, making the dust cleaner effective in various application environments.

Impressive Technical Specifications

The G1-1 Automatic Roller Coating Production Line is designed to meet the demanding requirements of modern manufacturing. With a total motor power of 57KW, it is capable of sustaining high performance over extended periods. The system requires a staffing of only 3-5 personnel, highlighting its efficiency in labor utilization. It consumes 700L of air per hour and operates at a line speed ranging from 5 to 20 meters per minute. The entire installation occupies a space of 6 by 4 meters, making it a compact yet powerful solution. With a production capacity of 1200 square meters per 8-hour shift and a production cycle of 15 days, the G1-1 is designed for high-volume output.

Cost-Effective Coating Process

The G1-1 production line is not only efficient but also cost-effective. The coating cost ranges from 3 to 5 yuan per square meter, making it an economical choice for large-scale production. This affordability, combined with its advanced features, makes the G1-1 an attractive investment for manufacturers looking to enhance their production capabilities without incurring excessive costs.

Versatile Application Substrates

The versatility of the G1-1 Automatic Roller Coating Production Line is evident in its wide range of application substrates. It is compatible with various materials, including calcium silicate board, honeycomb board, glass, glass-magnesium board, metal plate, door core board, MDF board, Osone board, leathers, gypsum board, photo frames, and hangers. This broad compatibility ensures that the system can be utilized across different industries, from construction and furniture manufacturing to automotive and aerospace sectors.

The G1-1 Automatic Roller Coating Production Line represents a significant advancement in the field of industrial manufacturing. Its intelligent unmanned production capabilities, combined with its specialized features for large panel handling, make it a standout solution for modern factories. The system’s efficiency, versatility, and cost-effectiveness provide a compelling case for its adoption, promising enhanced productivity and quality in panel painting processes. As industries continue to evolve and demand higher efficiency and precision, the G1-1 production line stands ready to meet these challenges, setting a new standard in automated manufacturing technology.