Buyer’s Guide to Roller Coating Machines for Construction Materials

August 15, 2024

August 15, 2024 Hits:457second

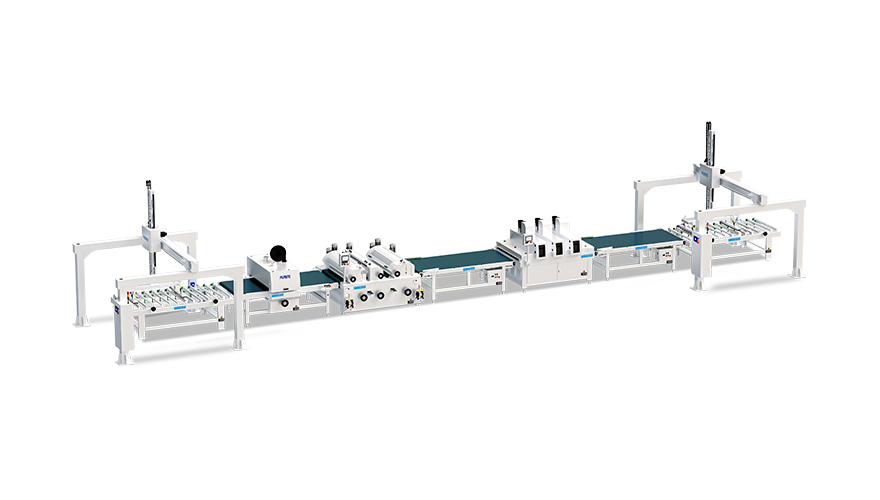

Hits:457secondIn the fast-paced world of construction materials, the choice of the right roller coating equipment can make all the difference in driving efficiency, quality, and profitability. As a leading Automatic Roller Coating Manufacturer, PURETE has established itself as a trusted partner for construction material producers seeking to optimize their coating processes.

Key Features and Specifications to Consider

When evaluating roller coating equipment, it's essential to look beyond the surface-level details and delve into the core functionalities that will directly impact your production outcomes.

Substrate Compatibility

One of the primary considerations is the versatility of the roller coating machine in handling a diverse range of substrates. PURETE's equipment is designed to accommodate a wide array of materials, including wood, glass, metal, and composite, allowing construction material manufacturers to streamline their production processes and maximize their investment.

Coating Thickness and Precision

The ability to apply coatings with consistent thickness and precision is crucial for maintaining product quality and performance. PURETE's roller coating machines incorporate advanced controls and monitoring systems to ensure accurate and uniform coating application, even on complex surfaces.

Ease of Maintenance and Cleaning

Minimizing downtime and maximizing equipment uptime are essential for maintaining high productivity levels. PURETE's roller coating machines are engineered with user-friendly maintenance and cleaning features, allowing your production team to quickly and effectively maintain the equipment, reducing operational disruptions.

Automation and Data Integration

In today's data-driven manufacturing landscape, the integration of intelligent automation and data reporting capabilities can provide a significant competitive edge. PURETE's roller coating machines are equipped with advanced automation features, such as automated defect detection and product sorting, as well as comprehensive data monitoring systems to optimize your production processes.

Comparing Different Roller Coating Machine Types

When it comes to roller coating equipment, construction material producers have a diverse range of options to choose from, each with its own unique features and capabilities.

Rotary Roller Coating Machines

Rotary roller coating machines are known for their ability to handle a wide variety of substrates and deliver high-quality, consistent coatings. PURETE's rotary systems are designed to optimize material usage, minimize waste, and provide exceptional finish quality.

Curtain Roller Coating Machines

Curtain roller coating machines offer a seamless, continuous coating process, making them ideal for applications where consistent, high-speed coating is required. PURETE's curtain roller coating solutions are engineered to provide exceptional coverage and finish performance.

Slot Die Roller Coating Machines

Slot die roller coating machines are particularly well-suited for the application of specialized coatings, such as functional or decorative finishes. PURETE's slot die systems leverage precise control and metering to deliver consistent, high-quality results.

Evaluating Roller Coating Machine Performance and Efficiency

When selecting a roller coating machine, it's crucial to assess its performance and efficiency to ensure it meets your production requirements.

Coating Quality and Consistency

Examine the machine's ability to deliver a uniform, defect-free coating that enhances the appearance and functionality of your construction materials. PURETE's roller coating equipment is renowned for its exceptional finish quality and consistency.

Productivity and Throughput

Consider the machine's production capacity and throughput to ensure it can keep up with your demand. PURETE's roller coating solutions are designed for high-speed, high-volume operation, maximizing your output and minimizing downtime.

Energy Efficiency and Environmental Impact

As sustainability becomes an increasingly important factor in the construction industry, evaluate the roller coating machine's energy efficiency and environmental impact. PURETE's equipment is engineered to minimize resource consumption and align with eco-friendly manufacturing practices.

Choosing the Right Roller Coating Machine for Your Application

When it comes to selecting the perfect roller coating machine for your construction material production, PURETE's experienced team is here to guide you every step of the way.

Tailored Solutions for Your Unique Needs

PURETE's commitment to innovation and customer-centricity means that they will work closely with you to understand your specific requirements and develop a customized roller coating solution that addresses your unique challenges and objectives.

Ongoing Support and Maintenance

Investing in a roller coating machine is not just about the equipment itself, but also the comprehensive support and maintenance services that ensure its long-term performance and reliability. PURETE's dedicated after-sales team provides ongoing technical support, preventive maintenance, and training to keep your production operations running smoothly.

Unlocking the True Potential of Your Construction Materials

By partnering with PURETE, a leading Automatic Roller Coating Manufacturer, construction material producers can unlock the true potential of their products, elevating quality, enhancing productivity, and driving sustainable growth. Whether you're seeking to optimize your existing coating processes or exploring new opportunities in the construction materials market, PURETE's innovative roller coating solutions and comprehensive support services will be your trusted partner in success.