Engineered Wood Lamination Solution: Advantages of the SCP3 Short-Cycle Press

April 17, 2025

April 17, 2025 Hits:20second

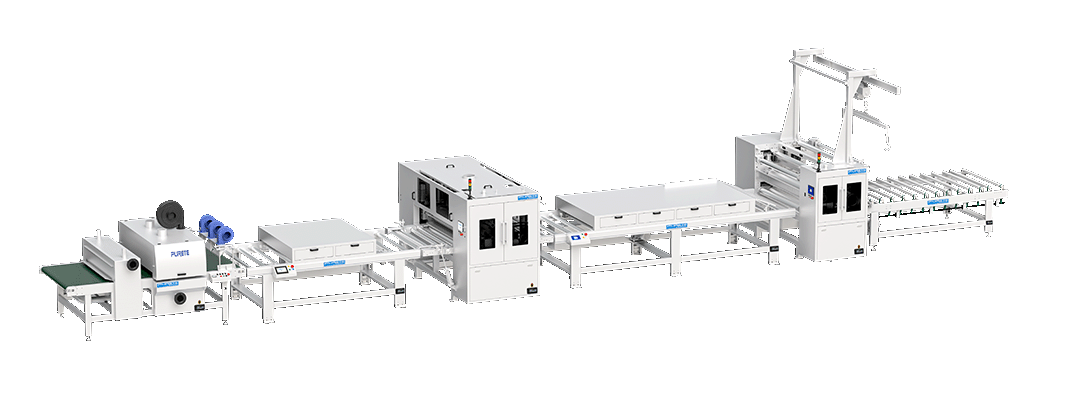

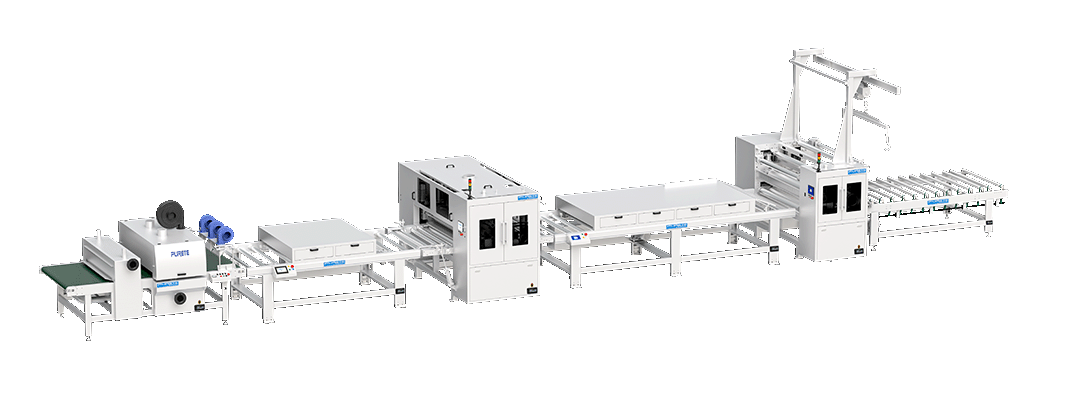

Hits:20secondAs demand continues to surge for engineered wood products in furniture, flooring, construction, and interior decoration, manufacturers face increasing pressure to deliver high-quality laminated panels quickly, efficiently, and cost-effectively. Among the advanced equipment shaping this transformation is the SCP3 short-cycle press—a cutting-edge solution designed specifically for high-performance lamination of engineered wood panels.

The SCP3 short-cycle press offers significant advancements in cycle time, surface quality, automation, and energy efficiency, making it a strategic investment for companies seeking to optimize their panel lamination operations.

What Is the SCP3 Short-Cycle Press?

The SCP3 short-cycle press is a third-generation, high-speed hydraulic press system tailored for the fast lamination of surfaces such as melamine-impregnated papers onto engineered wood panels, including particleboard, MDF, HDF, and plywood. Designed for short pressing cycles ranging from 8 to 30 seconds, the SCP3 integrates state-of-the-art technology in heating, pressure control, automation, and process synchronization.

Unlike conventional hot presses that require longer cycle times and manual interventions, the SCP3 is built for continuous industrial production, supporting both large-scale and customized manufacturing needs.

1. Superior Efficiency with Ultra-Fast Pressing Cycles

One of the core strengths of the SCP3 lies in its ultra-fast pressing cycles. With optimized thermal oil or electric heating systems and advanced hydraulic technology, the SCP3 can laminate panels in as little as 8–15 seconds, depending on the material and overlay type.

Benefits of rapid cycle times include:

Dramatically increased output per shift

Reduced operational costs per panel

Faster delivery for urgent or high-volume orders

Lower energy consumption per square meter produced

This enhanced efficiency is ideal for factories aiming to scale their output or meet tight production timelines without sacrificing product quality.

2. Exceptional Surface Quality and Uniformity

Engineered wood products often require high aesthetic value, particularly when used in visible furniture surfaces, cabinetry, or decorative wall panels. The SCP3 delivers perfectly uniform lamination, thanks to its precision control systems and consistent pressure distribution across the platen.

Surface quality advantages:

No bubbling, wrinkling, or uneven bonding

High-definition wood grain replication with embossing options

Excellent adhesion of melamine paper or decorative foils

Consistent gloss or matte finishes

Whether the end product demands smooth elegance or textured realism, the SCP3 guarantees reliable, repeatable surface finishes that enhance the value of engineered panels.

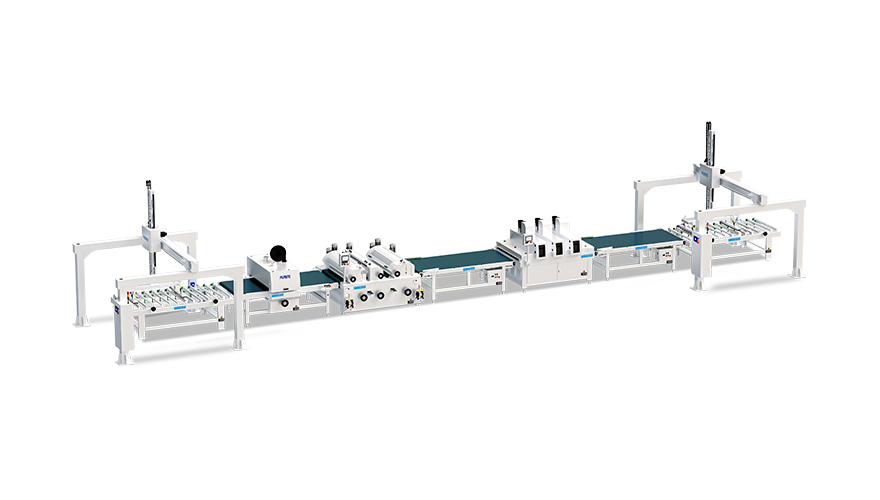

3. Advanced Automation and Intelligent Operation

The SCP3 short-cycle press is built with fully integrated automation, minimizing the need for manual handling and reducing human error. Its intelligent control system allows for recipe management, quality monitoring, and real-time adjustments based on material type or production volume.

Automation features include:

Auto-feeding and stacking systems

Preheating modules and cooling stations

Touchscreen interface with production analytics

Remote diagnostics and maintenance alerts

These capabilities enable continuous operation with minimal downtime, making the SCP3 ideal for high-demand environments and 24/7 production cycles.

4. Versatility Across Engineered Wood Applications

Engineered wood panels come in many forms and are used in a broad range of industries. The SCP3 short-cycle press accommodates various panel types, thicknesses, and overlay materials, providing unmatched flexibility for diverse manufacturing needs.

Applicable panel types:

Particle board (PB)

Medium-density fiberboard (MDF)

High-density fiberboard (HDF)

Oriented strand board (OSB)

Plywood and multi-layer boards

Compatible overlays:

Melamine-impregnated paper

Decorative films

Laminated foils

Synchronised embossed paper

This versatility allows manufacturers to respond quickly to changing customer demands and market trends—whether it’s classic wood grain finishes, modern high-gloss surfaces, or custom designer patterns.

5. Energy Efficiency and Environmental Responsibility

As sustainability becomes increasingly critical in industrial production, the SCP3 rises to the challenge with several energy-saving and eco-conscious features.

Eco-friendly highlights:

Optimized thermal insulation to reduce heat loss

Energy-efficient hydraulic systems with intelligent pressure control

Reduced VOC emissions with sealed lamination chambers

Compatibility with low-formaldehyde resins and recycled core materials

By reducing resource consumption and supporting the use of sustainable raw materials, the SCP3 helps manufacturers meet environmental regulations and green building certifications.

6. Compact Layout with Modular Expansion

Despite its high output capacity, the SCP3 boasts a compact footprint that fits well within existing factory layouts. Moreover, its modular design allows for easy expansion—additional modules for pre-heating, cooling, stacking, or quality control can be integrated as production demands grow.

This scalability makes the SCP3 suitable not only for large industrial operations but also for mid-sized factories looking to upgrade without major infrastructure overhauls.

SCP3 – A Future-Proof Lamination Solution for Engineered Wood

The SCP3 short-cycle press represents a new generation of efficiency and performance in the engineered wood industry. With fast pressing cycles, flawless surface finishes, automated operation, and environmentally conscious design, it meets the evolving demands of modern panel lamination—from mass production to high-end customization.

Whether producing laminate flooring, ready-to-assemble furniture, decorative wall panels, or kitchen cabinetry, the SCP3 empowers manufacturers to deliver top-tier products at scale, speed, and quality.

For engineered wood producers seeking a future-ready lamination solution, the SCP3 short-cycle press is more than just equipment—it’s a powerful tool for productivity, precision, and profitability.