Applications of Spray Painting Machines in Industrial Settings

April 07, 2025

April 07, 2025 Hits:70second

Hits:70secondSpray painting machines play a vital role in industrial processes, offering precision, efficiency, and consistent quality in applying coatings across a wide range of industries. These machines are designed to meet the demands of high-volume and high-quality production lines, making them indispensable for various industrial applications.

1. Automotive Industry

· Applications:

o Coating car bodies, bumpers, rims, and other components with precision.

o Applying anti-corrosion layers, primers, and clear coats.

· Benefits:

o Ensures uniform paint finishes and durability.

o Reduces material wastage and production time.

2. Consumer Electronics

· Applications:

o Painting device casings like smartphones, laptops, and home appliances.

o Adding decorative or protective coatings to plastic and metal components.

· Benefits:

o Provides a smooth, durable finish with aesthetic appeal.

o Meets strict tolerances and design specifications.

3. Furniture Manufacturing

· Applications:

o Applying finishes to wooden and metal furniture, including lacquer, varnish, and paint.

o Coating components of modular furniture and decorative pieces.

· Benefits:

o Achieves consistent coverage on intricate designs.

o Enhances durability and surface aesthetics.

4. Aerospace Industry

· Applications:

o Coating aircraft exteriors for corrosion resistance and aerodynamic efficiency.

o Painting interior components for fire resistance and aesthetic purposes.

· Benefits:

o Ensures precision and adherence to stringent quality standards.

o Reduces weight with optimized coating applications.

5. Construction and Infrastructure

· Applications:

o Painting structural components such as steel beams, pipes, and bridges.

o Coating walls, ceilings, and exterior surfaces for protection and aesthetics.

· Benefits:

o Protects against environmental wear and tear.

o Speeds up large-scale painting projects.

6. Metalworking Industry

· Applications:

o Applying protective coatings to machinery, tools, and fabricated metal parts.

o Adding decorative finishes to products like fences, gates, and hardware.

· Benefits:

o Prevents corrosion and extends the life of metal components.

o Enhances the appearance of finished products.

7. Plastic Manufacturing

· Applications:

o Coating plastic products such as automotive parts, consumer goods, and industrial components.

o Adding protective or decorative layers to fragile or intricate items.

· Benefits:

o Achieves a durable finish that adheres well to plastic surfaces.

o Enhances resistance to wear, UV exposure, and chemicals.

8. Industrial Equipment and Machinery

· Applications:

o Painting heavy machinery, equipment, and tools.

o Coating parts to resist wear, corrosion, or high temperatures.

· Benefits:

o Protects equipment under harsh operating conditions.

o Improves appearance and branding of machinery.

9. Glass and Ceramics

· Applications:

o Decorative and protective coatings for glass items such as bottles, windows, and ornaments.

o Coating ceramic tiles and products with glazes or paints.

· Benefits:

o Adds aesthetic value and functional durability.

o Enables mass production of high-quality finishes.

10. Packaging Industry

· Applications:

o Coating metal cans, plastic containers, and packaging materials.

o Applying protective or branding-related coatings.

· Benefits:

o Ensures compliance with food-grade and safety standards.

o Enhances the durability and visual appeal of packaging.

Spray painting machines offer versatile applications in industrial settings, from automotive manufacturing to aerospace, consumer electronics, and beyond. Their ability to provide uniform, high-quality coatings with minimal waste makes them a valuable asset for industries seeking to enhance productivity and meet stringent quality requirements. These machines are not only tools for efficiency but also key to achieving sustainable and cost-effective operations in modern industrial processes.

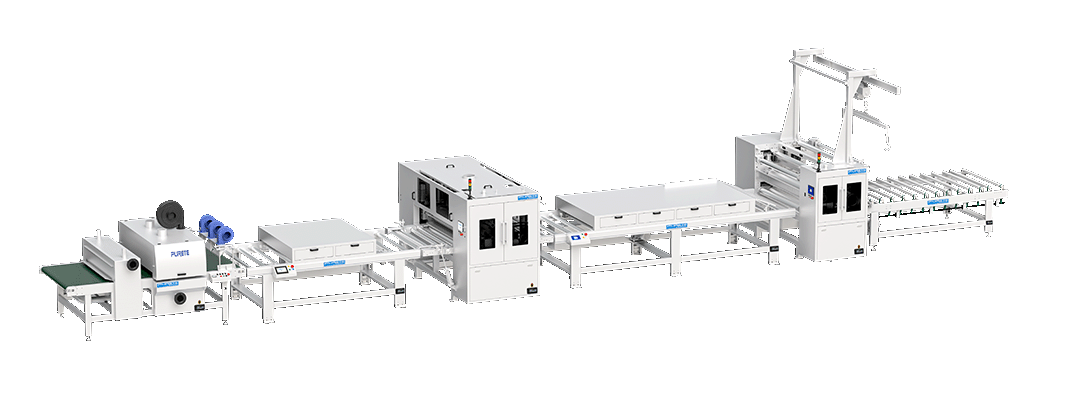

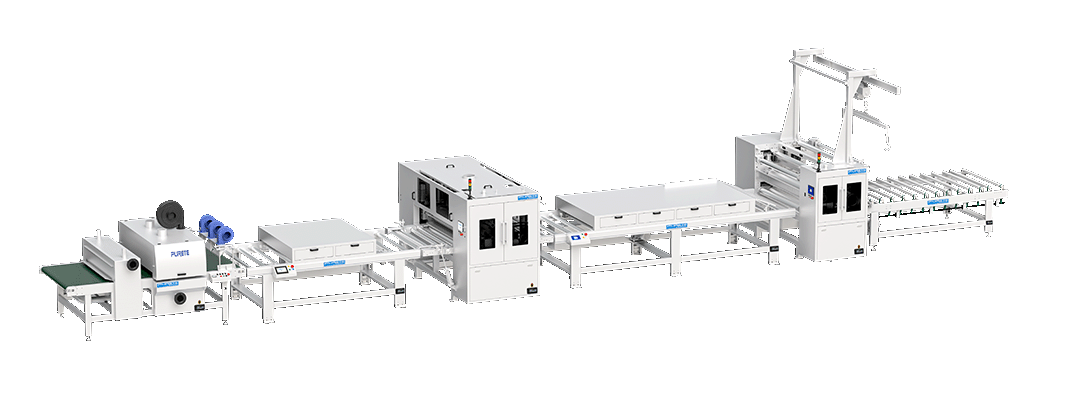

About Purete’s Spray Painting Machine Line

Purete specializes in advanced spray painting machine lines that provide high-quality, efficient, and sustainable painting solutions. Their lines integrate cutting-edge technology such as automated robotic arms, electrostatic spray systems, and precision controls that deliver exceptional consistency and minimal waste. Each system is designed to enhance productivity, reduce environmental impact, and meet strict quality standards. Whether for complex industrial applications or high-volume production, Purete's spray painting machine lines offer a customized solution that adapts to diverse manufacturing needs, ensuring reliable, high-quality finishes every time.

For more information about Purete's spray painting machine lines, visit Purete's website.