Sustainable Development Trends of the Intelligent Coating Machine System

April 14, 2025

April 14, 2025 Hits:23second

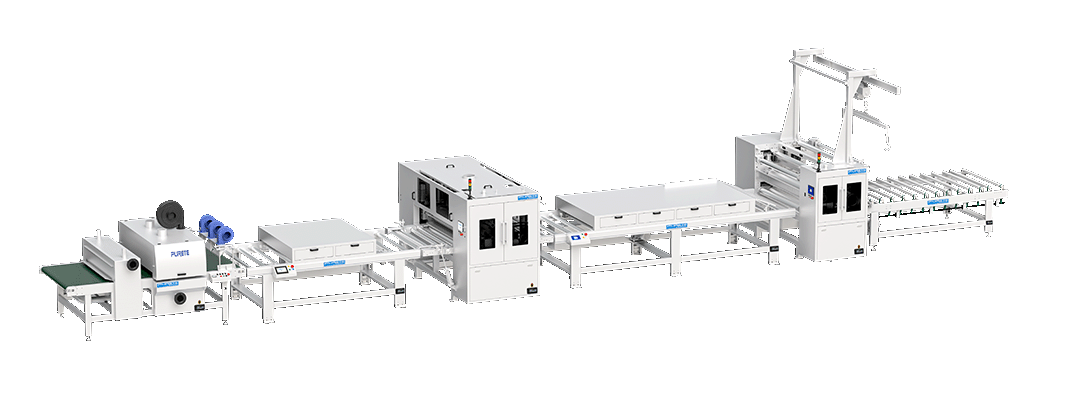

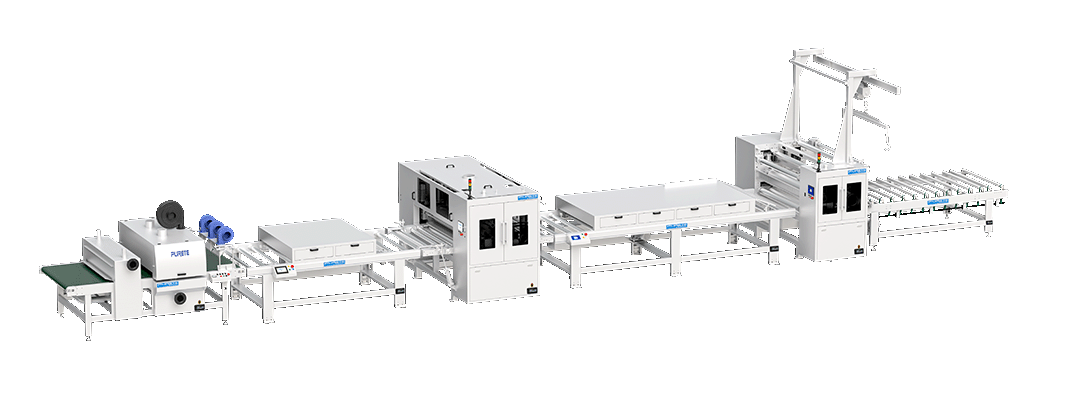

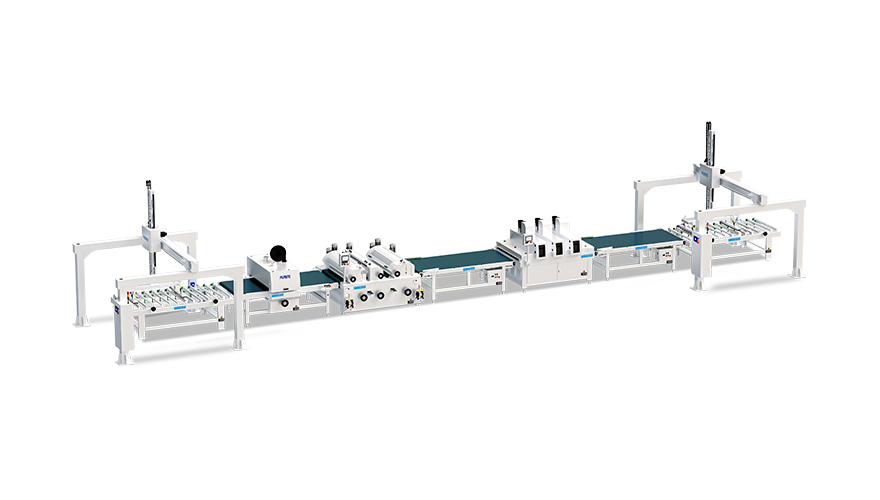

Hits:23secondIn recent years, sustainability has become a critical focus across multiple industries, including the manufacturing and surface treatment sectors. Among the technologies driving sustainable transformation is the Intelligent Coating Machine System. This advanced system integrates automation, digital control, environmental protection, and energy-saving features to optimize the coating process. As the world moves towards greener and more efficient production, the intelligent coating system is evolving in several key ways to align with sustainability goals.

1. Energy Efficiency and Resource Optimization

One of the most notable trends in the sustainable development of intelligent coating systems is the focus on energy efficiency. Traditional coating systems often consume significant amounts of electricity, compressed air, and coating materials, resulting in waste and high operational costs. In contrast, intelligent systems utilize precise control algorithms and sensors to monitor and adjust spray patterns, material flow rates, and drying processes in real time.

Modern intelligent systems are equipped with energy-saving modules such as variable-frequency drives (VFDs), smart heaters, and eco-mode operations. These features reduce power consumption by adapting to actual workload requirements, rather than operating at a constant full capacity. Additionally, advanced software can predict maintenance needs and optimize operational cycles, leading to lower energy usage and extended equipment lifespan.

2. Integration of Green Materials and Eco-Friendly Coating Processes

To meet stricter environmental regulations and consumer demand for eco-friendly products, intelligent coating systems are increasingly designed to handle water-based paints, low-VOC (volatile organic compound) coatings, and powder coatings. These materials significantly reduce harmful emissions and contribute to cleaner air in production environments.

Intelligent machines can automatically adjust to different material viscosities and drying requirements, making them highly versatile and efficient in green manufacturing. By reducing overspray and improving material transfer efficiency, these systems minimize waste and ensure uniform coating, which reduces the need for rework and material loss.

3. Digitalization and Industry 4.0 Integration

Another major trend in the sustainable development of intelligent coating systems is the integration with Industry 4.0 technologies. Through IoT (Internet of Things) connectivity, real-time data monitoring, and cloud computing, manufacturers can gain deeper insights into their coating processes and make data-driven decisions to enhance sustainability.

Digital twins—virtual representations of the physical coating process—allow engineers to simulate different scenarios and optimize workflows before implementation. Predictive maintenance powered by AI and machine learning ensures that the equipment remains in optimal condition, minimizing downtime and unnecessary repairs. This digital transformation helps reduce resource consumption and production disruptions, making operations more sustainable and cost-effective.

4. Closed-Loop Systems and Recycling Capabilities

Sustainability is also achieved through closed-loop systems integrated into intelligent coating machines. These systems collect and recycle unused coating materials, solvents, and rinse water, reducing the need for fresh raw materials and minimizing environmental discharge.

For example, automatic paint recovery systems capture overspray and filter it for reuse, while solvent recycling units purify cleaning solvents for multiple cycles of use. These innovations not only reduce waste and environmental impact but also lower operating costs for manufacturers.

5. Modular and Scalable Designs for Longevity

Modern intelligent coating systems are being designed with modular components and scalable architectures, making them easier to upgrade or reconfigure as needs change. This sustainable design approach extends the lifespan of equipment and reduces the frequency of full system replacements, which would otherwise contribute to electronic and industrial waste.

Manufacturers can add new modules—such as enhanced control interfaces, environmental monitoring units, or robotics arms—without having to overhaul the entire system. This adaptability supports long-term sustainability by promoting reuse, repair, and responsible resource management.

6. Human-Machine Collaboration and Worker Safety

Sustainability also includes the well-being of the workforce. Intelligent coating systems are increasingly being equipped with user-friendly interfaces, automation functions, and robotic assistance that reduce manual labor and exposure to hazardous chemicals.

By reducing the need for operators to be physically involved in high-risk tasks like manual spraying or chemical cleaning, the system enhances occupational safety. This aligns with the broader goal of sustainable development, which includes social responsibility alongside environmental and economic considerations.

7. Global Regulatory Compliance and Sustainability Certifications

Intelligent coating machine systems are being engineered to comply with international environmental standards such as RoHS, REACH, and ISO 14001. These certifications demonstrate a commitment to sustainability and help manufacturers gain trust in global markets.

Advanced systems come with built-in reporting tools that track energy consumption, material usage, emissions, and waste. These reports support ESG (Environmental, Social, and Governance) initiatives and help companies meet compliance requirements more effectively.

The evolution of the intelligent coating machine system represents a significant leap forward in sustainable manufacturing. By combining energy efficiency, green materials, digital intelligence, and human-centered design, these systems are reshaping the coating industry with a clear focus on environmental responsibility and long-term viability.

As global awareness of climate change and resource scarcity continues to grow, the adoption of intelligent, sustainable coating solutions will become a competitive necessity rather than a technological luxury. Investing in such systems not only ensures compliance and efficiency but also supports a cleaner, healthier, and more resilient industrial future.