January 09th

How does roller coating differ from other methods of applying coatings, such as spray painting or dip coating?

Roller coating, spray painting, and dip coating are all techniques used to apply coatings to various surfaces, but they differ significantly in application methods, precision, and ideal use cases.

January 06th

Applications of Intelligent Coating Machine Systems Across Industries

Intelligent coating machine systems have revolutionized the way materials are coated in modern manufacturing. By integrating cutting-edge technologies like artificial intelligence (AI), real-time monitoring, and automated controls, these systems deliver exceptional precision, efficiency, and adaptability. Their applications span a wide range of industries, meeting diverse requirements from protective coatings to aesthetic finishes.

January 03rd

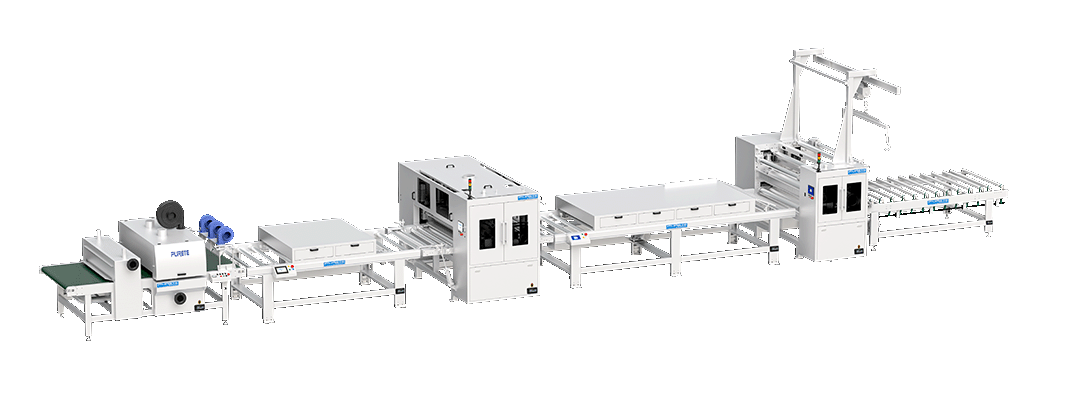

Intelligent Coating Machine System Working Principle

Intelligent coating machine systems have become a cornerstone in modern industrial production, enabling precise, efficient, and high-quality coating processes. These systems integrate advanced technologies such as automation, sensors, artificial intelligence (AI), and real-time data analysis.

January 02nd

Future Trends in Automatic Spray Painting Machine Systems

The automatic spray painting machine systems industry is continuously evolving, driven by technological advancements, increasing demand for efficiency, sustainability, and customization. As industries demand higher-quality finishes, faster production rates, and reduced environmental impact, the future of these systems is expected to be marked by innovation in automation, digitalization, and eco-friendly solutions.

December 24th

What is the Function of a Spray Painting Machine?

A spray painting machine is specifically designed to apply paint or coatings to surfaces efficiently, evenly, and with high precision. It automates the painting process, ensuring consistent coverage, reducing material waste, and enhancing productivity in various industrial, commercial, and residential applications.

December 23rd

How does the PUR laminating process differ from other laminating methods?

The PUR laminating machine process (Polyurethane Reactive) differs from other laminating methods primarily due to its adhesive properties, bonding mechanisms, and resulting durability.

December 19th

Short-Cycle Press Production Line: The Secret to Fast and Efficient Production

short-cycle press production line is a highly automated system designed for rapid lamination or pressing processes. It applies pressure, heat, and sometimes adhesives to bind materials like wood, veneers, laminates, or composites into finished panels or components.

December 18th

What are the benefits of using a spray painting machine line?

Investing in a spray painting machine line not only boosts productivity but also ensures superior finish quality, reduces costs, and promotes a safer, more sustainable workplace.

December 13th

What are the common applications of PUR laminating machines in the printing industry?

PUR laminating machines (Polyurethane Reactive laminating machines) are widely used in the printing industry for their ability to create high-quality, durable, and flexible laminated products.