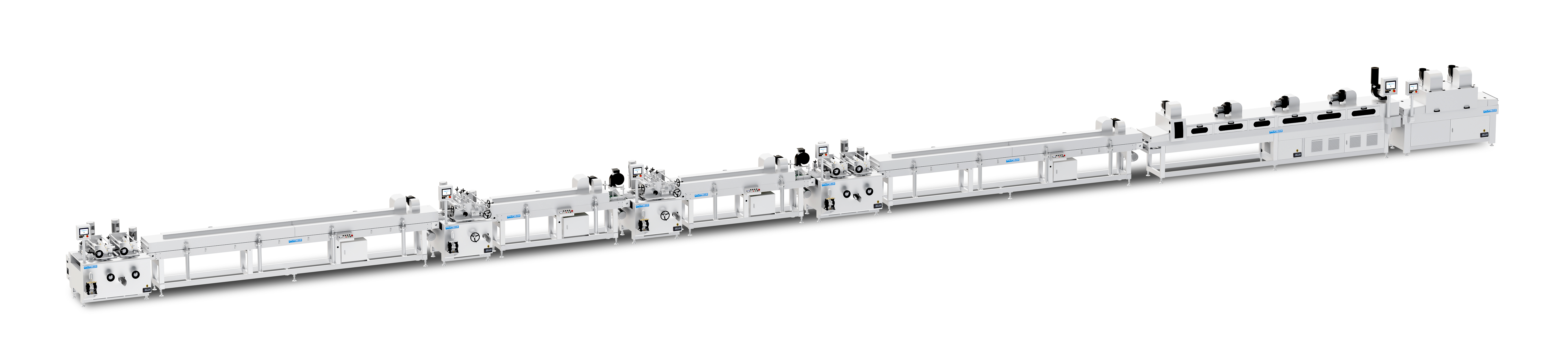

F4 Soft touch edge banding production line

Achieving the integration of edges and surfaces.The edges have been processed by an 186/254 nanometer excimer machine to achieve super matt and soft-touch effect, paired with a flat skin matte board for edge banding to achieve the integration of edges and surfaces.

Composed of dust cleaner, 6m infrared leveling, monochrome printing, 3m Infrared leveling, duble roller coating machine, nano Excimer UV system, and four lamps UV curing.

Read more

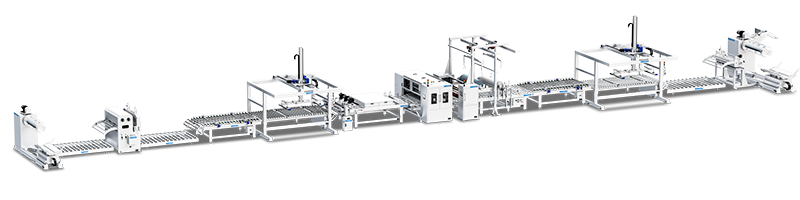

T4 Roll-to-Roll Laminating Production Line

The T4 Roll-to-Roll Laminating Production Line is specifically designed for laminating various decorative films and functional materials onto steel, stainless steel, and aluminum plates. With its continuous roll-to-roll processing and precise PUR or hot-melt adhesive coating, this line achieves excellent surface bonding, high flatness, and durable decorative effects for metal substrates.

This production line is ideal for manufacturers of metal decorative panels, elevator panels, appliance surfaces, interior wall cladding, and aluminum composite materials. Its fully automated workflow ensures high efficiency, stable quality, and reduced manual handling, making it well-suited for large-scale industrial applications.

Composed of: Aluminum product unwinding machine, feed shears, alignment roller conveyor, sheet loading gantry, infrared preheating machine, gluing machine, laminating machine, long-side trimming machine, alignment roller conveyor, board flipping machine, and unloading system.

Read more

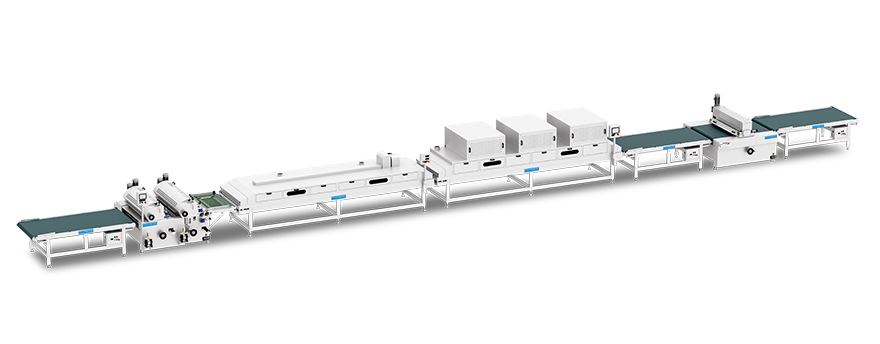

G4 Veneer Roller Coating Production Line for Decorative Panels

The G4 veneer roller coating production line is designed for industrial-scale production of high-quality decorative panels. Offering strong chemical resistance, long service life, and environmentally friendly antibacterial coatings, it supports ultra-thin veneers as thin as 0.2mm. This advanced system features a double-roller coater, dual 6-meter IR heating ovens, and a hot roller machine, ensuring precise and uniform coating application. Ideal for manufacturers seeking efficiency, consistent quality, and sustainable production, the G4 line delivers superior surface finishes while reducing labor costs and enhancing overall productivity.

Read more